Cutting device for canning based on sponge absorption

A technology of cutting device and absorbing device, which is applied in metal processing and other directions, can solve problems such as unsanitary and nutrient waste, achieve the effects of reducing waste, avoiding one-time use, and improving hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

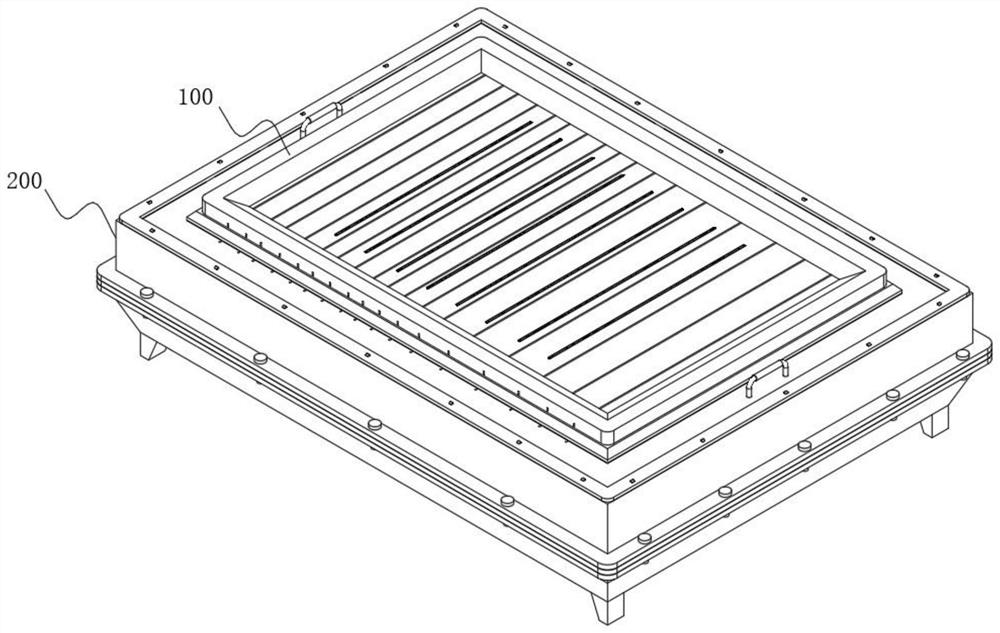

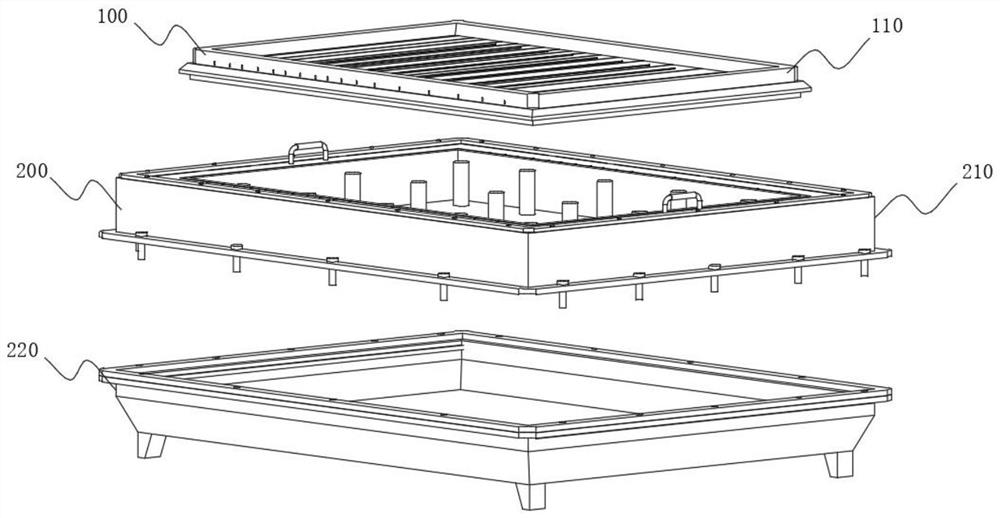

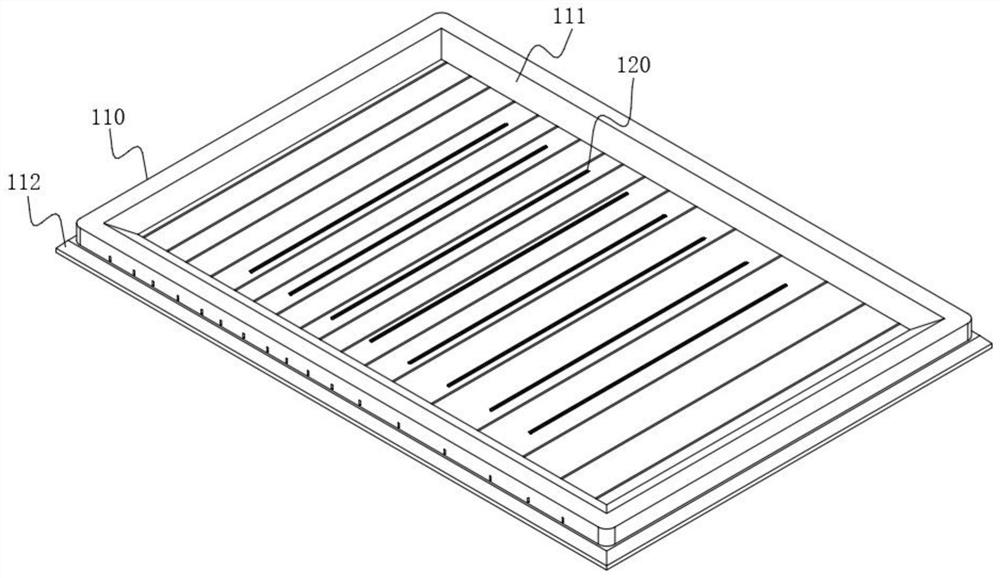

[0060] see Figure 1-Figure 13 As shown, one of the purposes of this embodiment is to provide a cutting device for can processing based on sponge absorption, including a cutting device 100 and a moisture absorbing device 200 arranged at the bottom of the cutting device 100, characterized in that: the cutting device 100 includes a cutting base 110, the top of the cutting base 110 is provided with a cutting groove 111, the cutting groove 111 is a prism-shaped groove with a large top area and a small bottom area, so that the side wall of the groove is inclined inward, so that the liquid on the surface flows into the bottom of the groove under the action of gravity , the bottom in the cutting groove 111 is equidistantly provided with a plurality of cutting mechanisms 120 along the straight line direction, and the cutting mechanism 120 comprises a mounting groove 121, and a blade 122 is arranged in the mounting groove 121, and the included angle between the blade 122 and the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com