Anti-explosion impact crushing energy-absorbing beam at bottom of vehicle

A technology of explosive impact and energy-absorbing beam, which is applied in vehicle parts, bumpers, transportation and packaging, etc., can solve the problems of increasing the injury of people in the vehicle and the absorption of the passenger compartment, and achieve the effect of improving the lightning protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

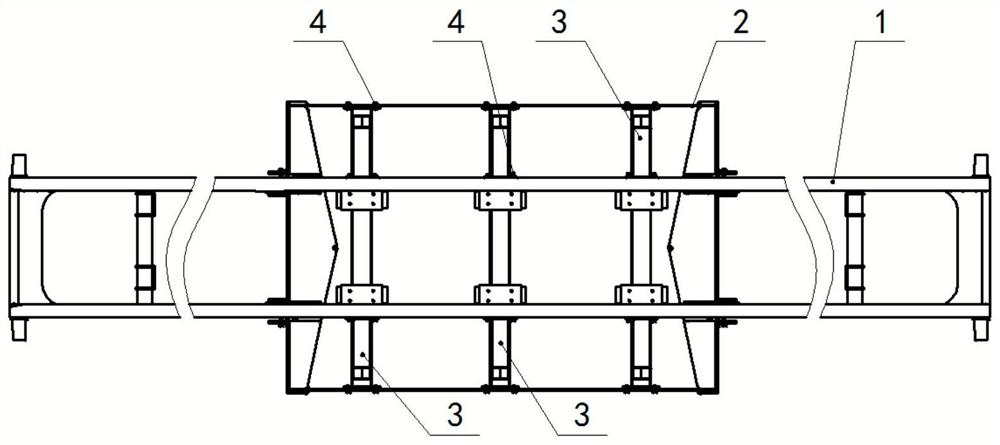

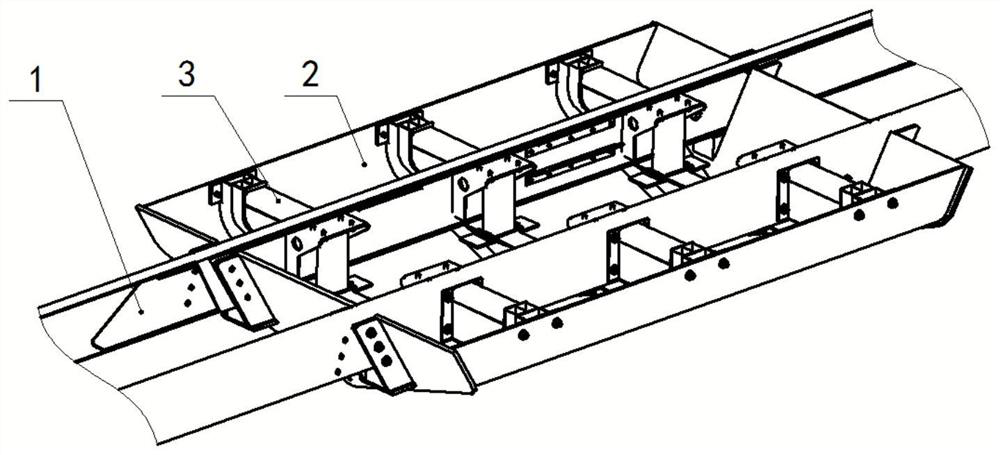

[0028] The anti-explosion impact crushing energy-absorbing beam at the bottom of the vehicle in this embodiment has a structure such as figure 1 , figure 2 , image 3 as shown, figure 1 It is the general layout drawing, which shows the layout of the anti-explosion impact crushing energy-absorbing beams at the bottom of the vehicle. It includes chassis girder 1, bottom armor 2, crushing energy-absorbing beam 3, and bolt a4.

[0029] The crush energy-absorbing beams 3 are installed on the chassis girder 1 through bolts a4, and are evenly distributed. The bottom armor 2 is located under the crush energy-absorbing beam, and is installed on the side of the crush energy-absorbing beam 3 through bolts a4.

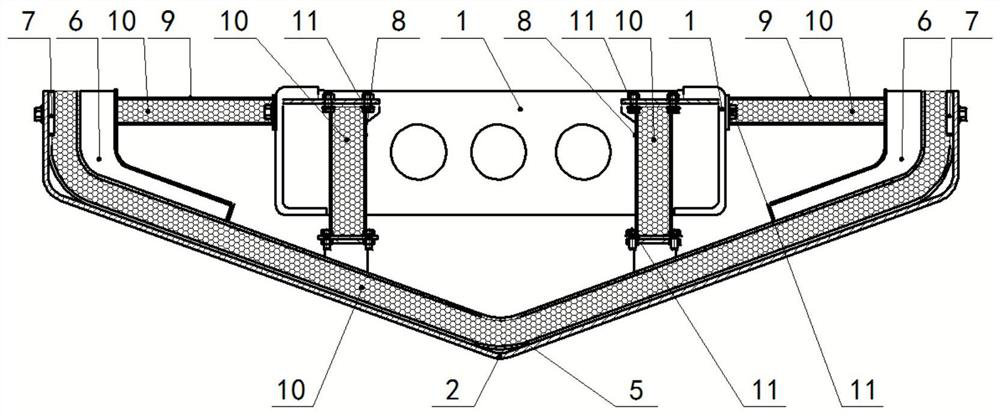

[0030] figure 2 It is a side sectional view of the anti-explosion impact crushing energy-absorbing beam at the bottom, which shows the whole structure of the anti-explosion impact crushing energy-absorbing beam at the bottom of the vehicle. Including front beam 5, side bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com