Patents

Literature

52results about How to "Reduce upload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

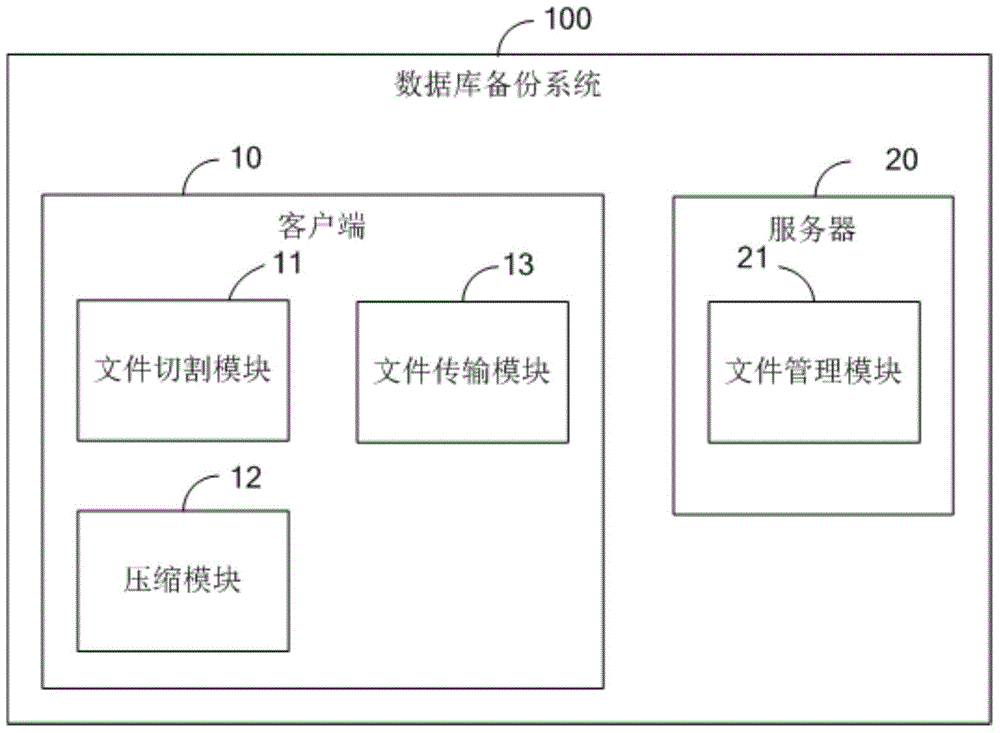

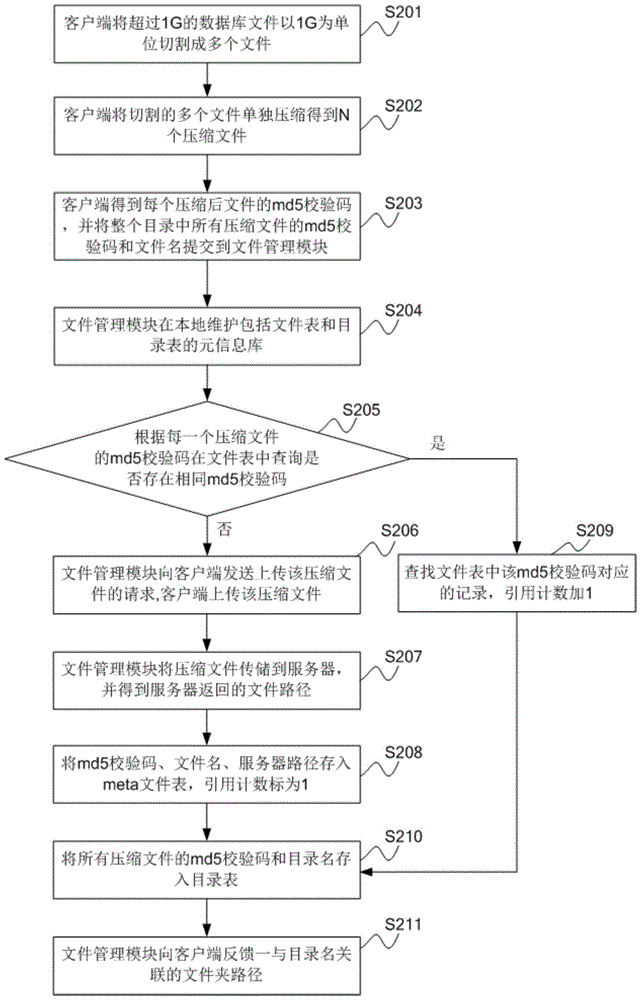

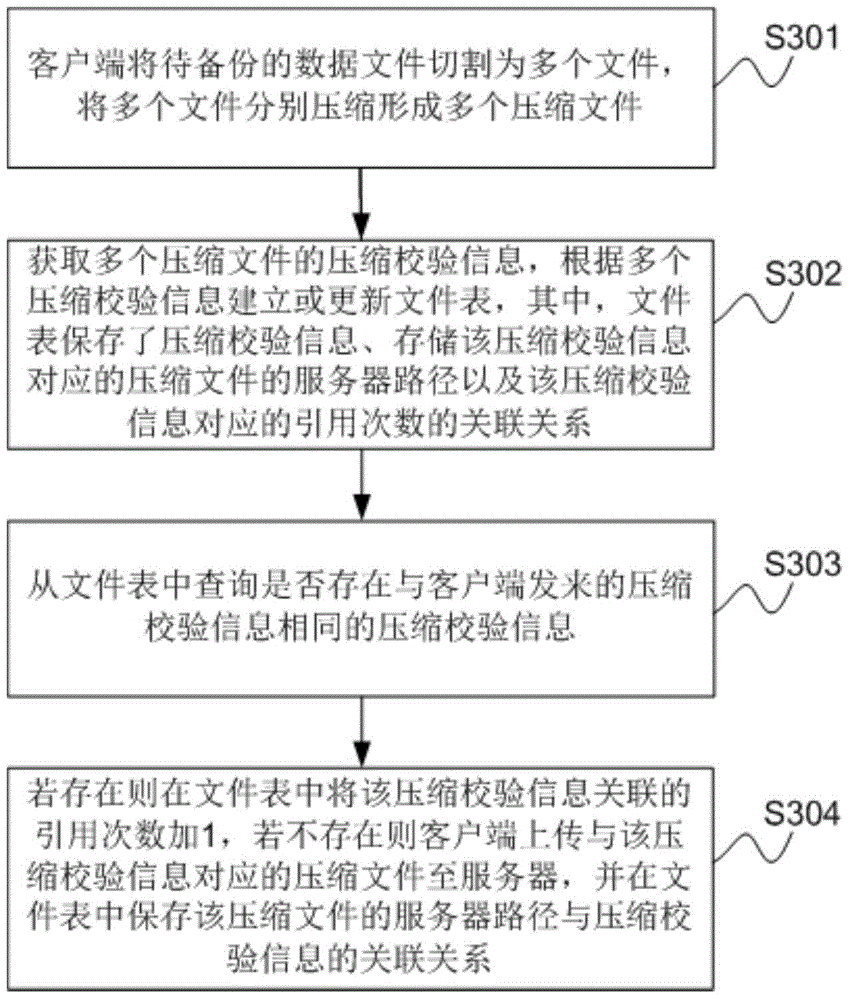

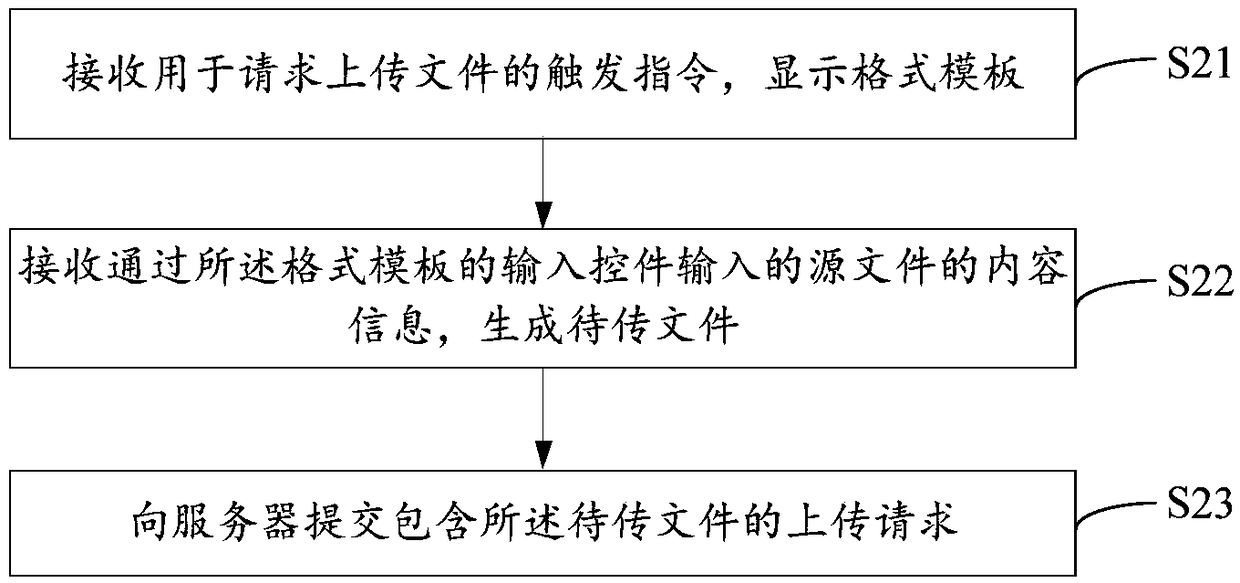

Method and system for database backup

InactiveCN105095300AShorten the timeSave space costRedundant operation error correctionSpecial data processing applicationsDatabase backupData file

The invention discloses a method and a system for database backup for solving the problems of long elapsed time and large server occupied space of the existing data backup process. The method comprises the following steps that a client cuts a to-be-backed-up data file into a plurality of files and respectively compresses the files into a plurality of compressed files; and the client obtains compression check messages of the compressed files and establishes or updates a file table according to a plurality of compression check messages, wherein the file table stores incidence relations among the compression check messages, a server path for storing the compressed files corresponding to the compression check messages, and citations corresponding to the compression check messages. According to the method and the system, the uploading file quantity is reduced through de-weight optimization, so that consumption of the server space and the uploading time can be reduced.

Owner:ALIBABA GRP HLDG LTD

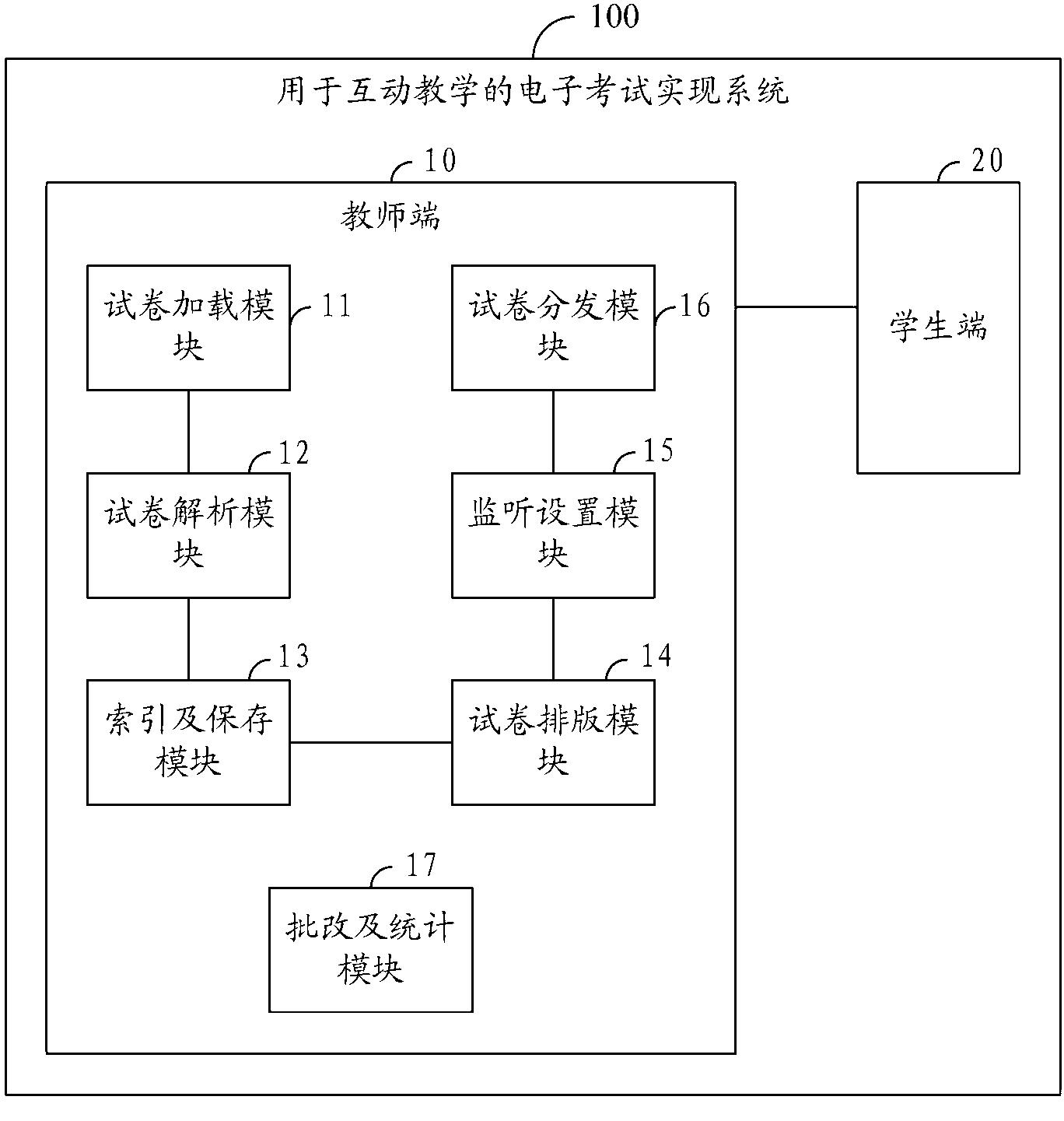

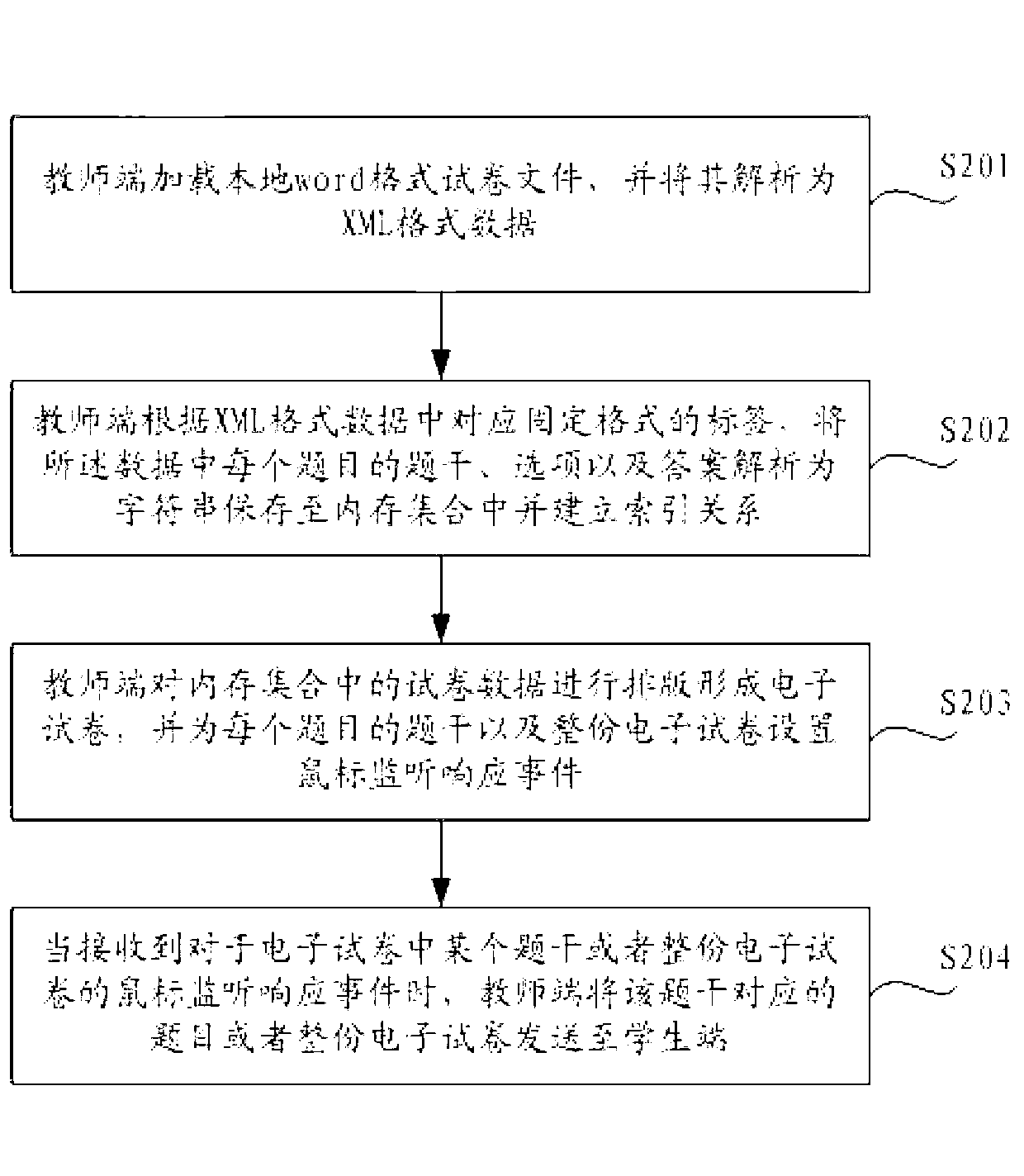

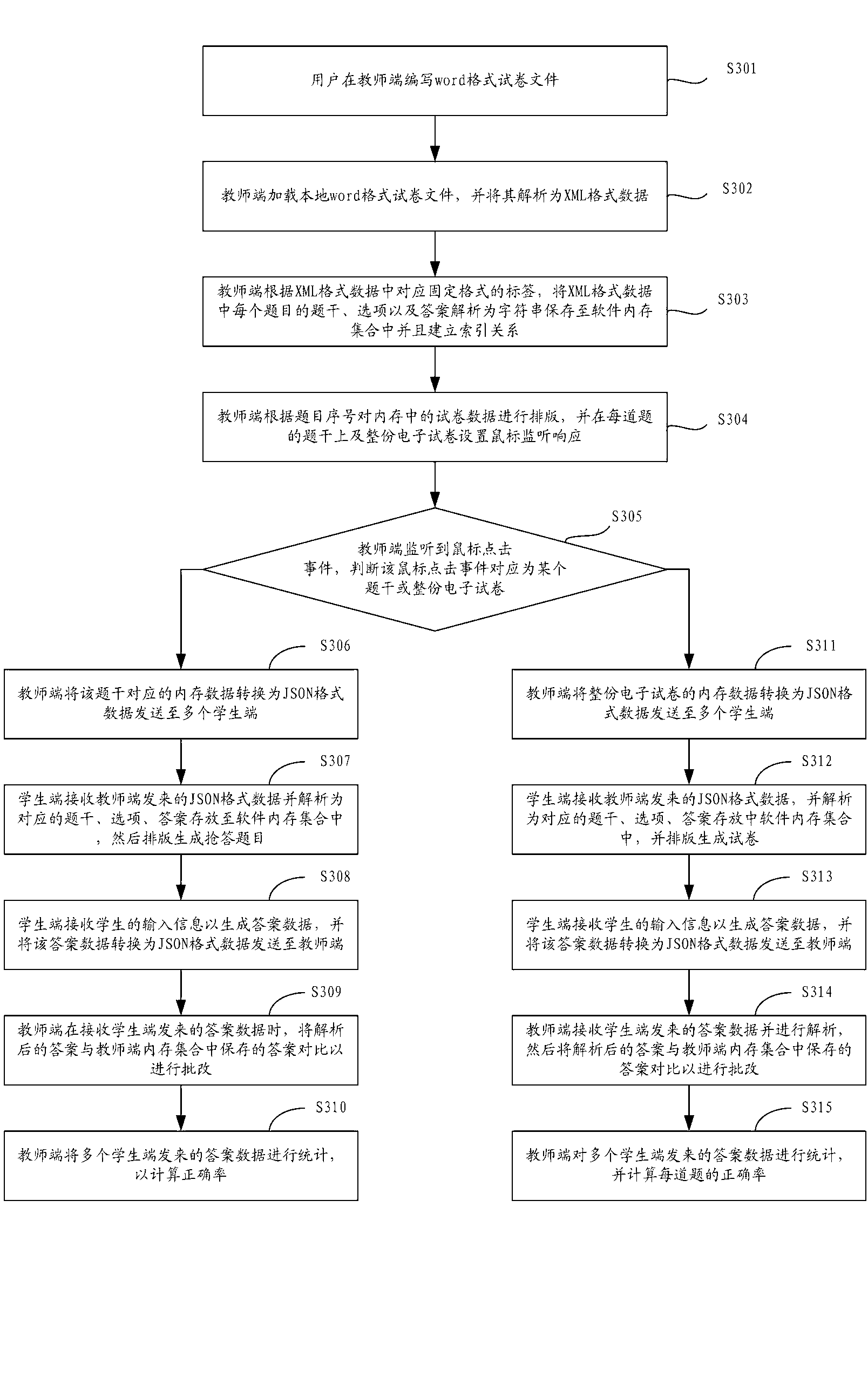

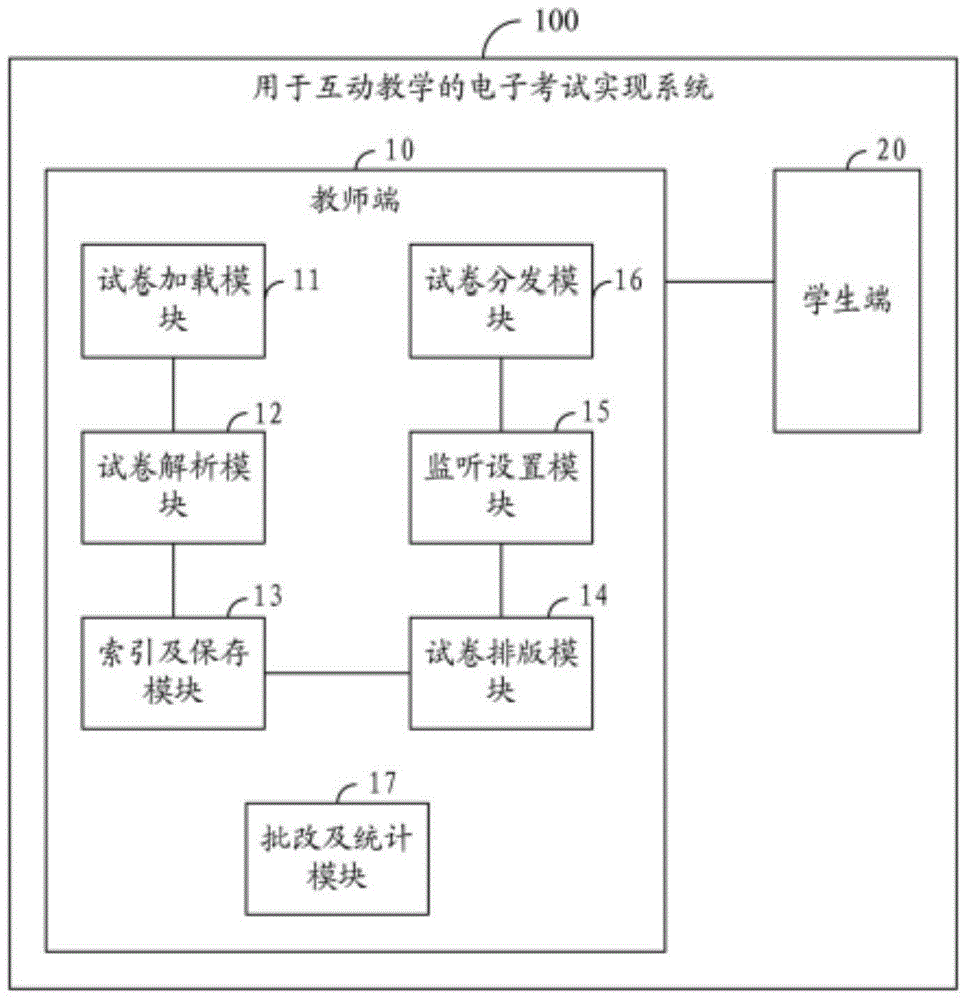

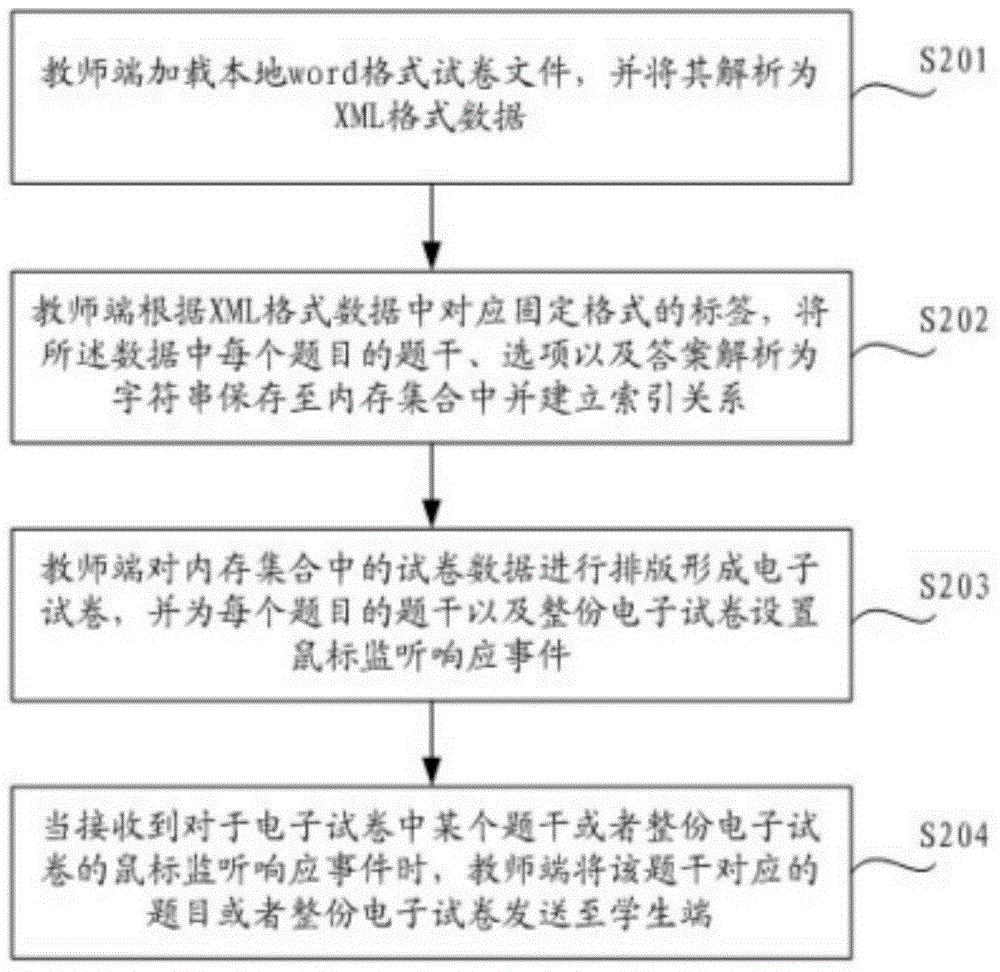

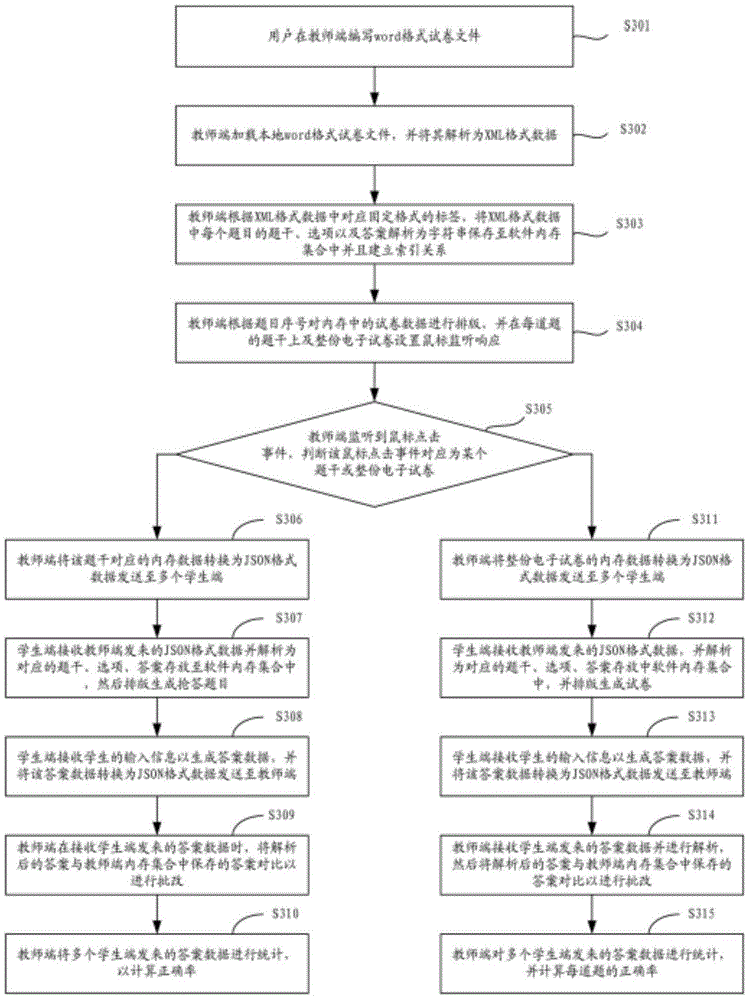

Electric examination achieving method and system used for interaction teaching

The invention provides an electric examination achieving method and system used for interaction teaching, and the electric examination achieving method and system used for the interaction teaching is suitable for the field of electric teaching. The electric examination achieving method used for the interaction teaching comprises the following steps that a local word form test paper file is loaded by a teacher terminal and the word form test paper file is analyzed into XML form data; the subject, the options and answers of each topic are analyzed into character strings to be stored in memory collection and index relationship is built according to labels corresponding to a fixed format in the XML form data; the test paper data in the memory collection are composed to form an electric test paper and mouse monitor response events are set for the subject of each topic and the whole electric test paper, when the mouse monitor response events of a certain subject or the whole electric examination test paper are received, the topic corresponding to the subject or the whole electric test paper is sent to a student terminal. Therefore, the electric examination achieving method and system used for the interaction teaching solves the problem of abnormal import of the electric test paper caused by a network reason in the prior art, a teacher can design and edit test questions conveniently, and multi-applicability of the electric test paper is achieved.

Owner:深圳市乐望教育科技有限公司

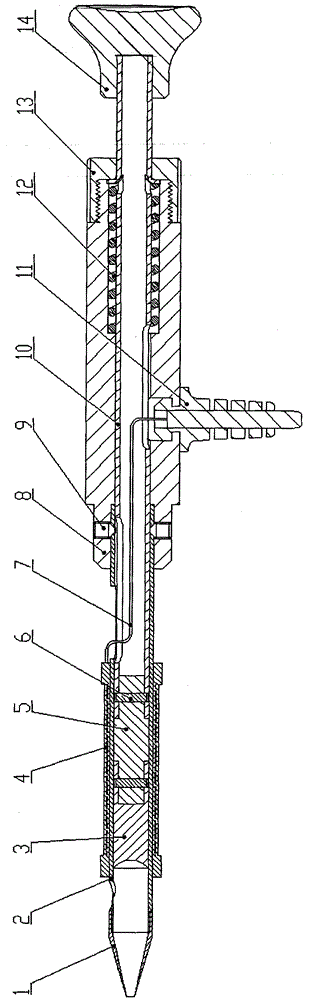

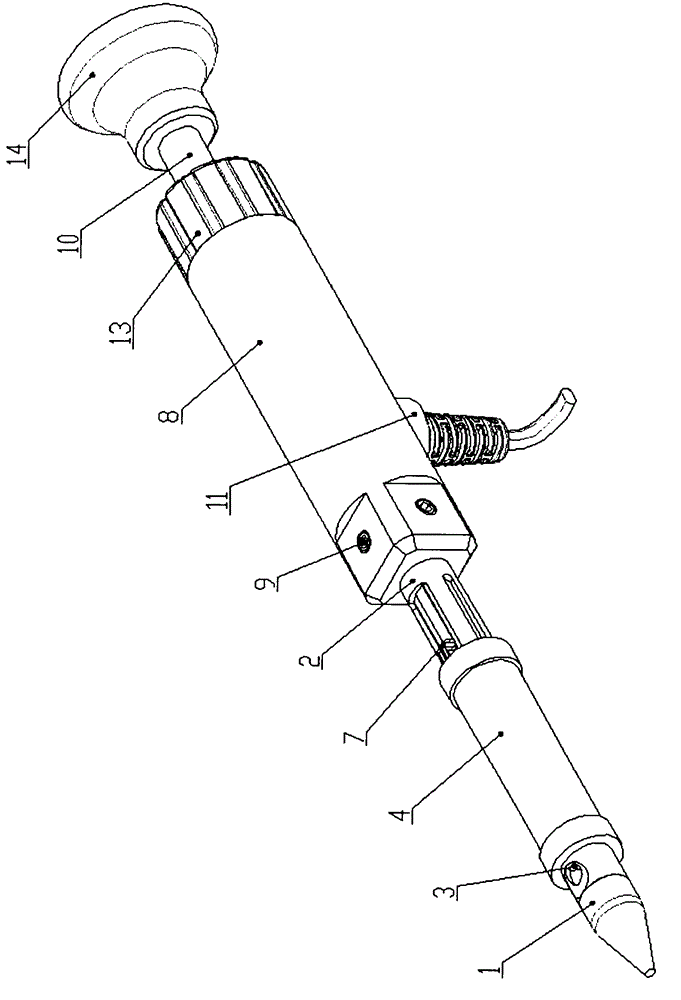

Tin-dropping electric soldering iron

The invention belongs to an electric soldering iron in an electric appliance repairing industry, and particularly relates to a tin-dropping electric soldering iron. The tin-dropping electric soldering iron consists of a soldering nozzle, an outer bushing, a piston, a heating tube, a heat insulation pushing rod, a pin, a conducting wire, a handle, a tightening screw, a pushing rod, a conducting wire connector, a return spring, a rear cover and a button. When in welding, a tin soldering wire penetrates through a wire feeding hole, the button is pressed down, an annular edge of the piston and an edge of the outer bushing collectively cut off the tin soldering wire and seal the tin soldering wire into a tin melting cavity between the soldering nozzle and the piston, and the tin soldering liquid is pushed out through a tin outlet hole in the front end of the soldering nozzle by continuously pressing the button. When the piston is reset under the effect of the return spring, pressure difference can be formed in the tin melting cavity and used for recycling the soldering tin, i.e. the tin-dropping electric soldering iron integrates the function of the electric soldering iron and the function of a tin absorber. By adopting the tin-dropping electric soldering iron, the problem of the volatilization of rosin in the tin soldering wire easily caused by a tin-dropping electric soldering iron can be overcome, and the problems that the pseudo soldering and desoldering are easily caused by the small contact area between the tin soldering wire and a soldering head of an ordinary electric soldering iron, the flow direction and the flow rate of the soldering tin are difficult to control, and the electric soldering iron needs to be operated by two hands can be overcome.

Owner:南通瑞卓模塑有限公司

Interactive teaching method based on information engineering and system thereof

InactiveCN104464422ASimple designEasy to editData processing applicationsElectrical appliancesInformatics engineeringTest question

The invention relates to the technical field of education and teaching, and particularly relates to an interactive teaching method based on information engineering and a system thereof. The interactive teaching method comprises the steps that a local word format test paper file is loaded by a teacher-terminal and parsed into XML format data; a question stem, options and an answer of each question are parsed into character strings to be saved to a memory set according to corresponding fixed formats of tags in the XML format data and an index relation is established; test paper data in the memory set are typeset so that electronic test paper is formed, and mouse listening response event is set for the question stem of each question and the whole electronic test paper; and when the mouse listening response event for a certain question stem in the electronic test paper or the whole electronic test paper is received, the corresponding question of the question stem or the whole electronic test paper is sent to a student-terminal. A problem of importing abnormity of the electronic test paper due to network reasons in the prior art is solved so that test question designing and editing are facilitated for the teacher, and multi-application of the electronic test paper is realized.

Owner:ZHENGZHOU XUESHENGBAO ELECTRONICS SCI & TECH

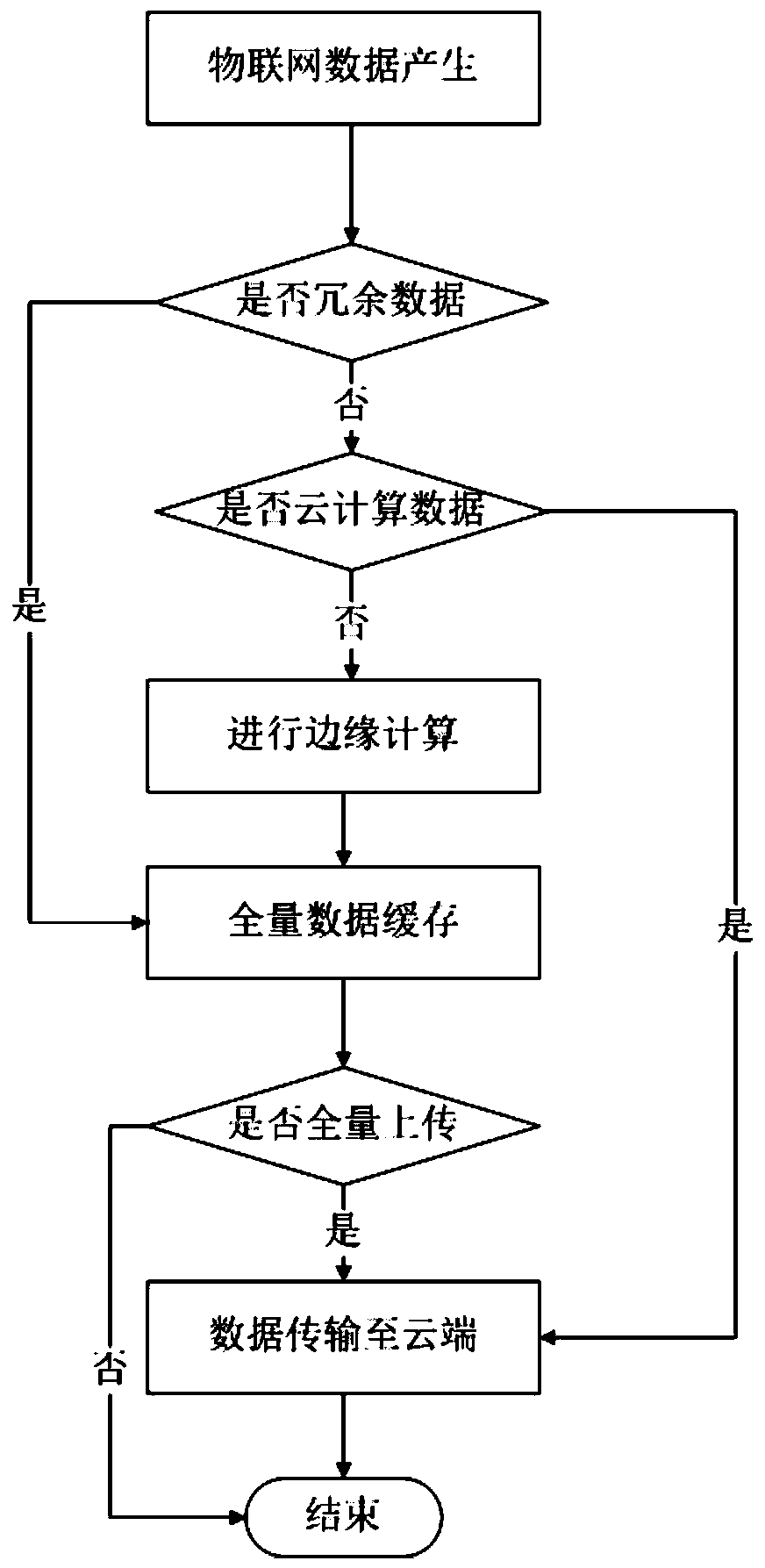

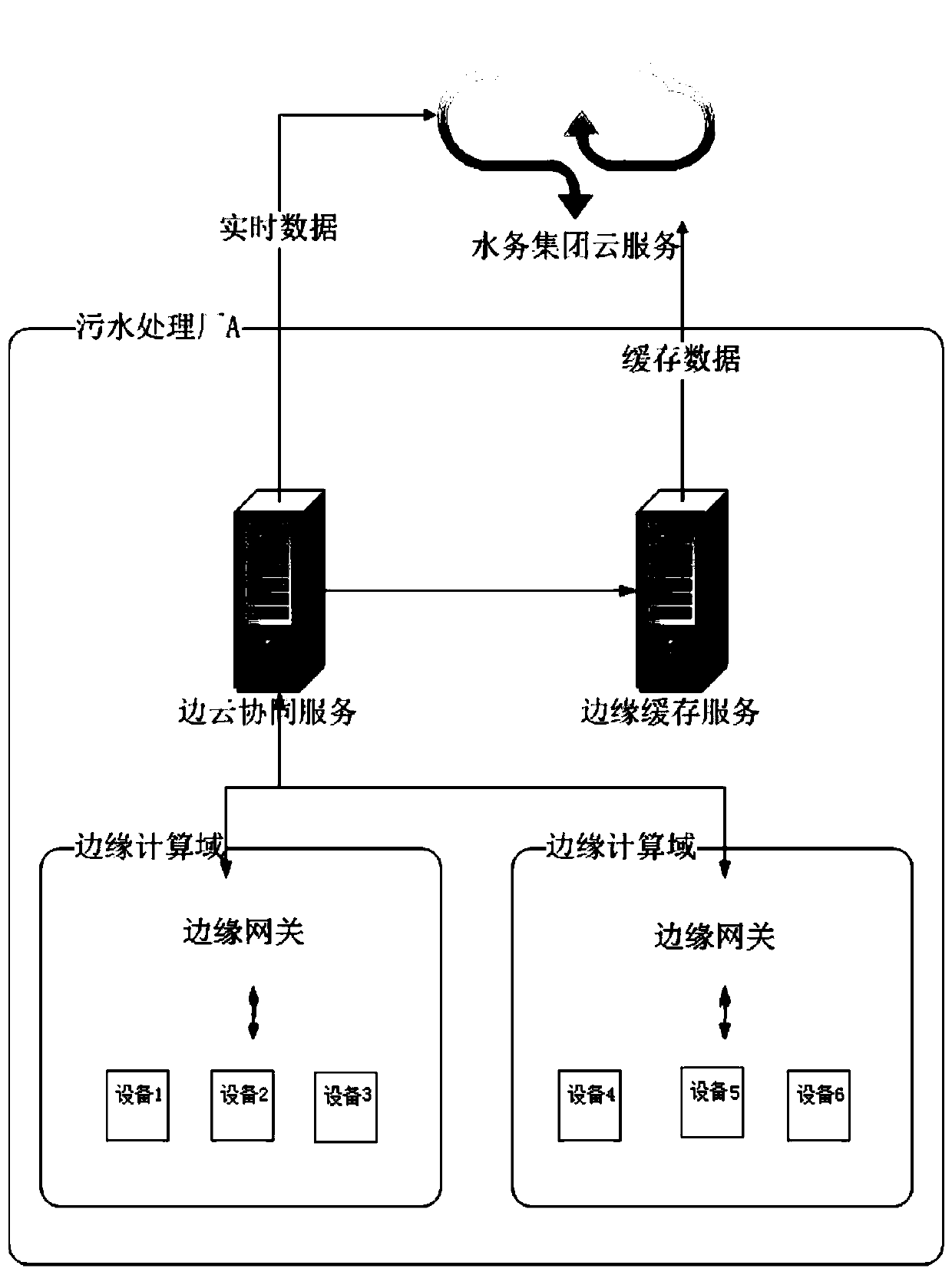

Edge cloud data collaboration method and system for sewage treatment Internet of Things application

InactiveCN110933154AOptimize the synchronization mechanismGuaranteed uploadDigital data information retrievalTransmissionCache serverEdge computing

The invention relates to an edge cloud data collaboration method for an sewage treatment Internet of Things application. The method comprises the following steps: sewage treatment Internet of Things data is obtained; the side cloud collaboration server preprocesses the sewage treatment Internet of Things data, removes redundant data, and divides remaining data into cloud computing data and edge computing data; the edge cloud collaboration server transmits the cloud computing data to a cloud server for real-time computing, and transmits the edge computing data to an edge computing node for real-time computing; the edge calculation data and the redundant data are stored in an edge cache server; and the edge cache server transmits the stored edge computing data and redundant data to the cloudserver by using the network bandwidth margin and the network valley period. Compared with the prior art, the method has the advantages that the influence of time delay on real-time online services can be effectively reduced, the waste of data assets can be reduced while the network overhead is reduced, and the real-time load pressure of a cloud platform can be reduced.

Owner:SHANGHAI SIIC LONGCHUANG SMARTER ENERGY TECH CO LTD

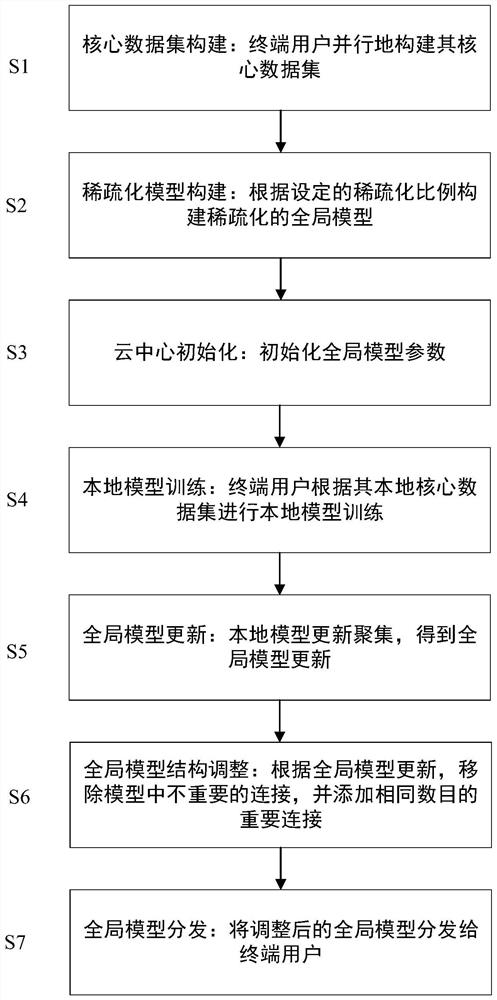

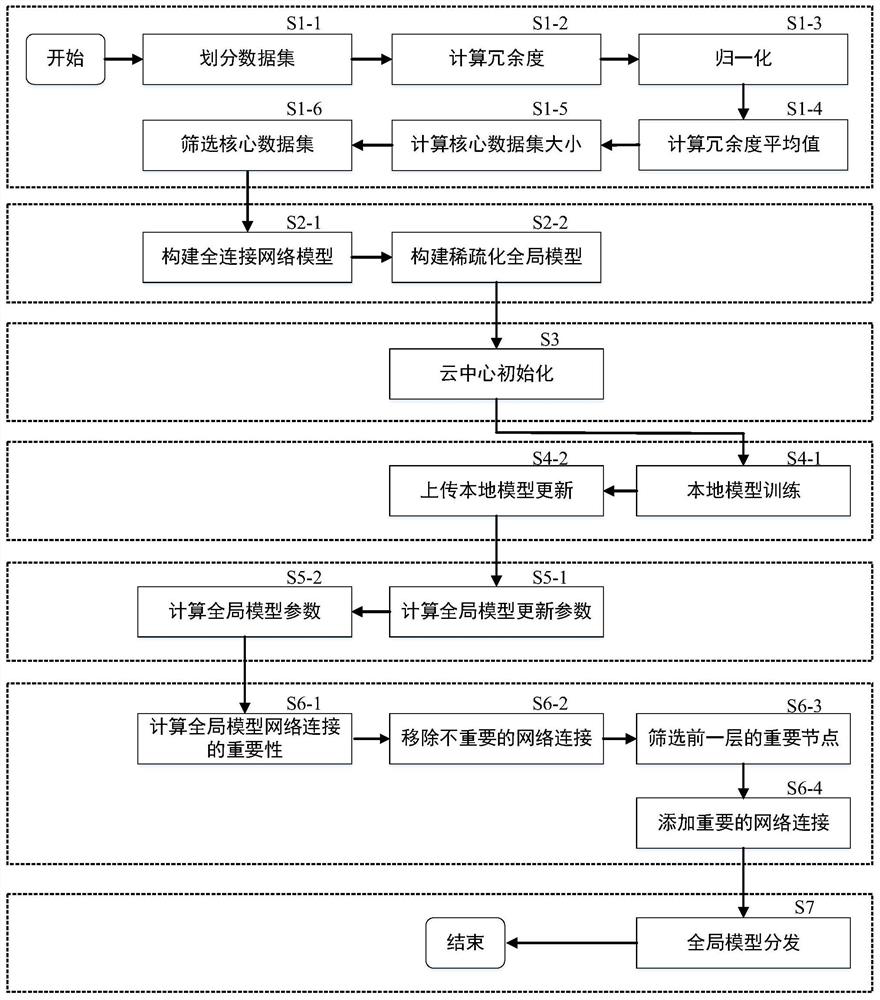

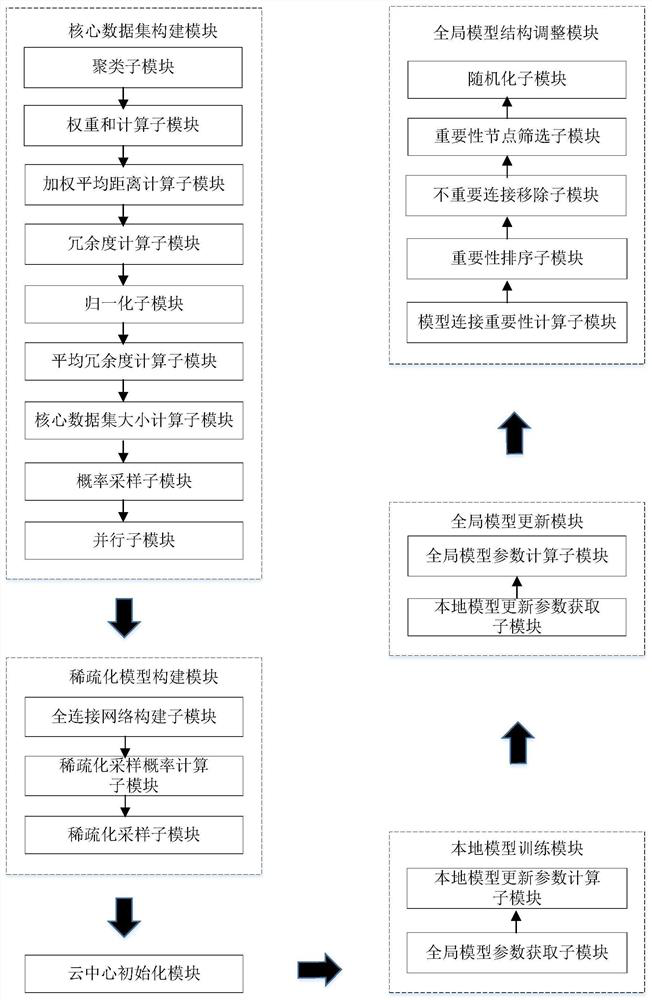

Federated learning communication traffic optimization method and system based on core data set

InactiveCN112364913AReduce uploadReduce trafficCharacter and pattern recognitionMachine learningData setNetwork structure

The invention relates to the field of federated machine learning, and discloses a federated learning communication traffic optimization method and system based on a core data set. The method comprisesthe following steps that: firstly, each terminal user screens out core data from local training data in parallel, a cloud center constructs a sparse global model according to a set sparse proportion,and each terminal user performs local model training according to the screened local core data to obtain a local model update; then, in order to enable the global model to adapt to local core data better, the cloud center adjusts the network structure of the global model according to global model update obtained by an aggregating local model update, including the two steps of removing unimportantconnection and adding important connection; and finally, the cloud center distributes the adjusted global model to each terminal user, and iterates the above steps until the global model converges. By screening the core data from the terminal user and deploying the adaptive sparse network model, the uploading of the model parameters of the terminal user and the cloud center is reduced, and the problem of high communication cost caused by frequent transmission of high-dimensional update parameters between the terminal user and the cloud center in the federated learning technology is essentially solved.

Owner:CHONGQING UNIV

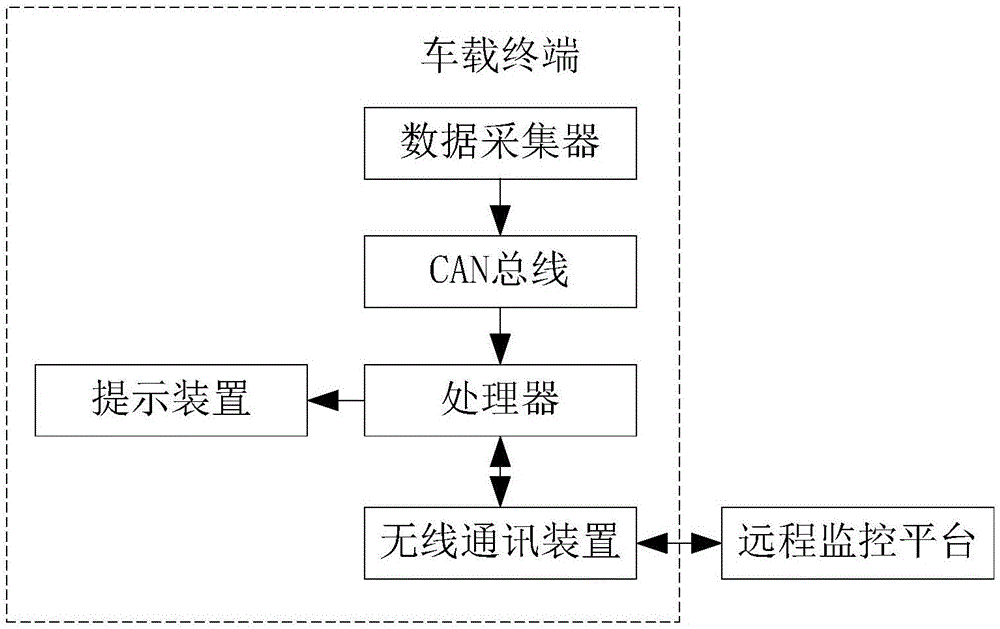

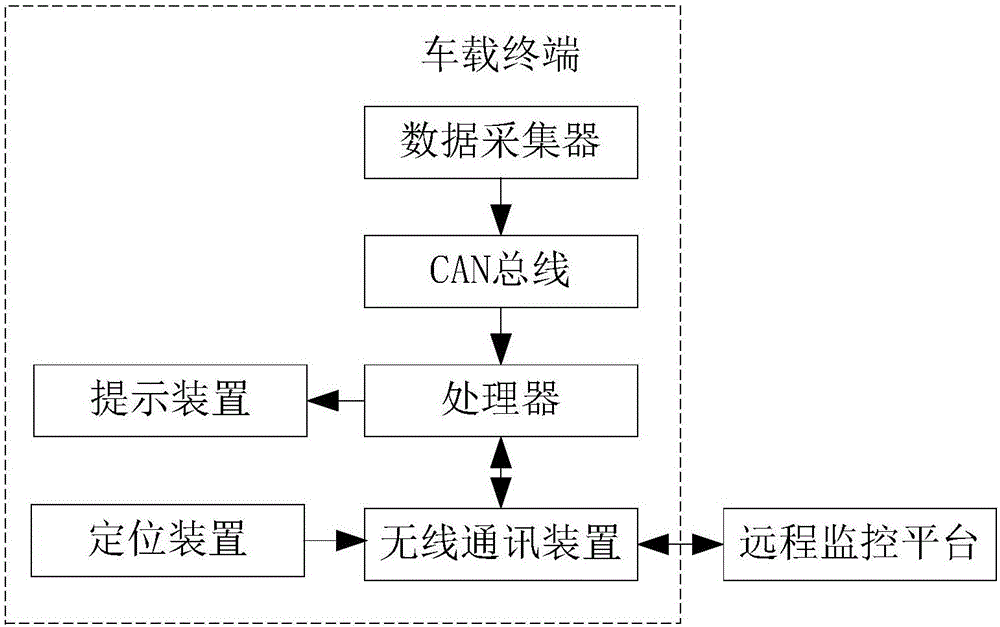

Remote monitoring system of vehicle and method

InactiveCN106686075AKeep abreast of health statusEasy maintenanceElectric/fluid circuitBus networksRemote patient monitoringTechnician

Owner:象翌微链科技发展有限公司

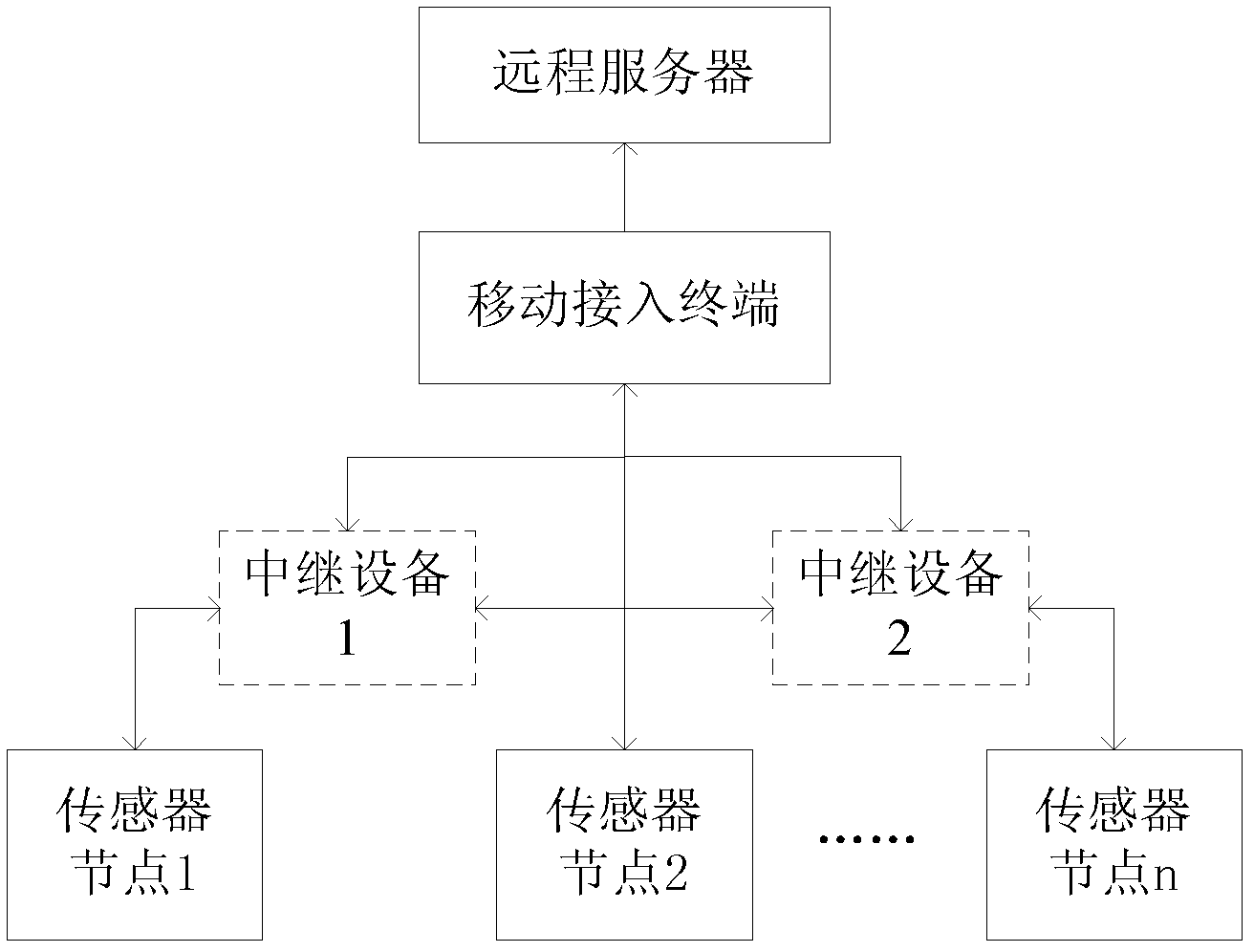

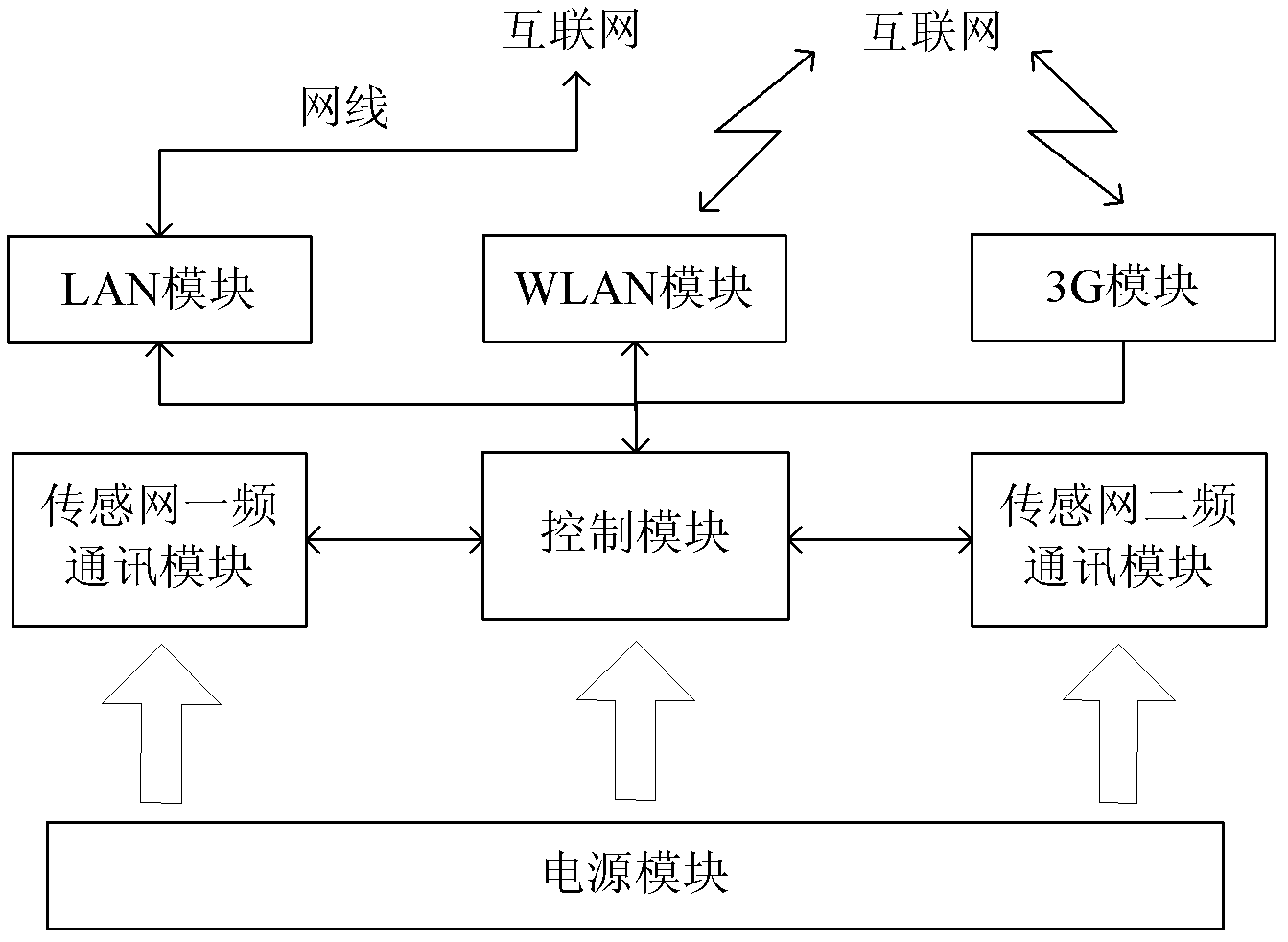

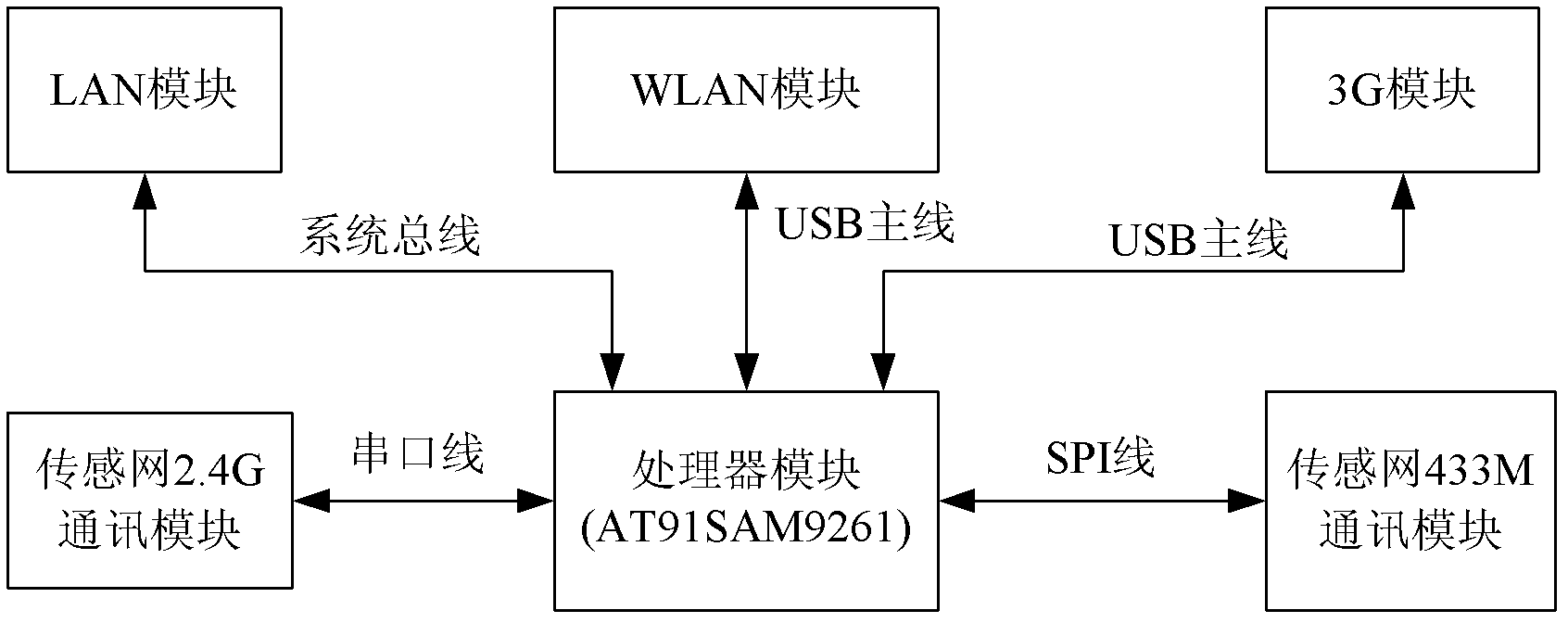

Mobile access terminal used in wireless sensor network and system thereof

InactiveCN102724734AIntegrity guaranteedReduce maintenance costsAssess restrictionNetwork topologiesMobile wireless sensor networkWireless mesh network

The invention discloses a mobile access terminal used in a wireless sensor network and a system thereof. The terminal comprise a control module, a sensing network first frequency communication module and a sensing network second frequency communication module, wherein the control module emits a receiving data command to the sensing network first frequency communication module and / or the sensing network second frequency communication module according to a work frequency of a wireless sensing network; The sensing network first frequency communication module monitors and receives data emitted by wireless sensor nodes of the wireless sensing network as a 2.4 GHz frequency range according to the receiving data command of the control module; the sensing network second frequency communication module monitors and receives the data emitted by the wireless sensor nodes of the wireless sensing network as a 433MHz frequency range according to the receiving data command of the control module. By using the terminal and the system of the invention, the terminal can monitor the data under the different frequencies and can automatically select an optimal mode to access the network according to changes of environment so that integrity of the data can be guaranteed.

Owner:BEIJING LOIT TECH

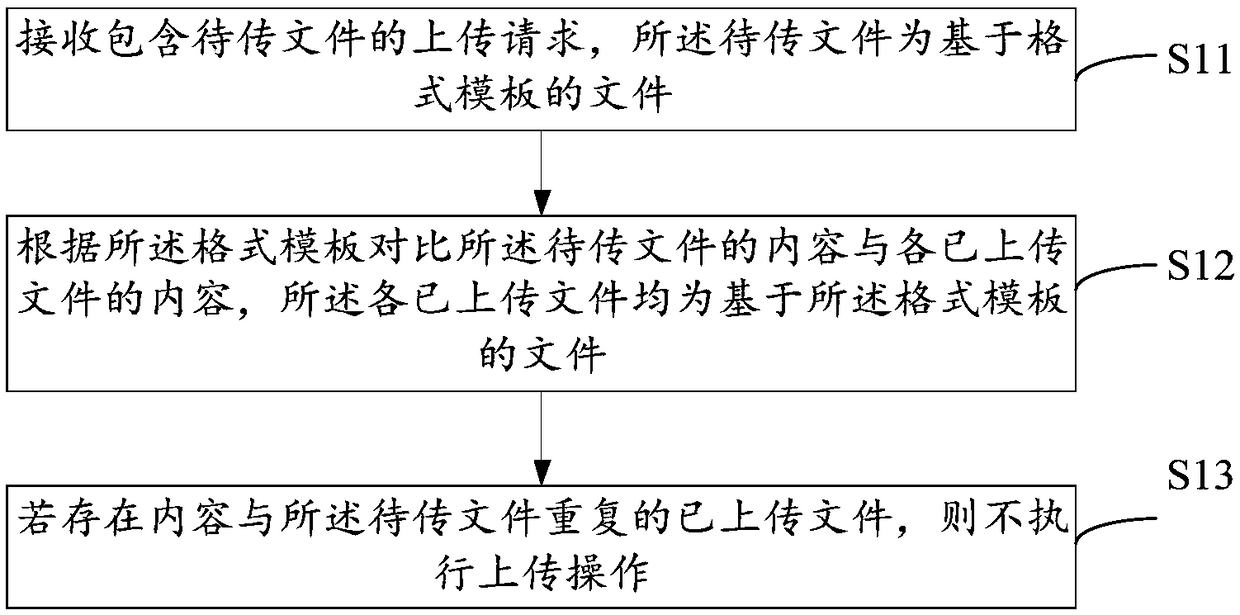

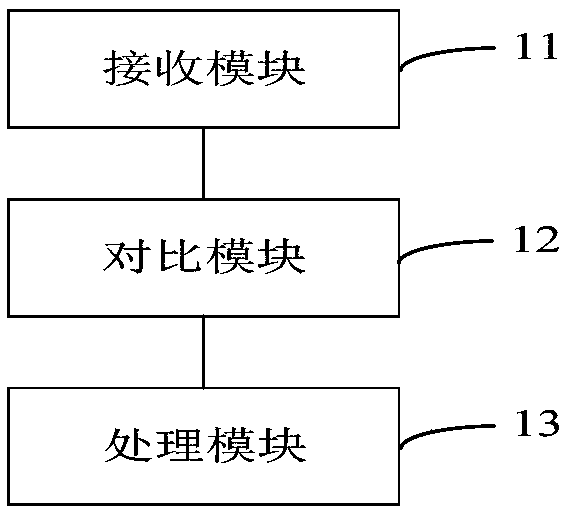

Method for preventing file from being uploaded repeatedly, and control method and device thereof

PendingCN109241009AAvoid duplicate uploadsReduce riskDigital data information retrievalNatural language data processingOperating system

Owner:CHINA PING AN LIFE INSURANCE CO LTD

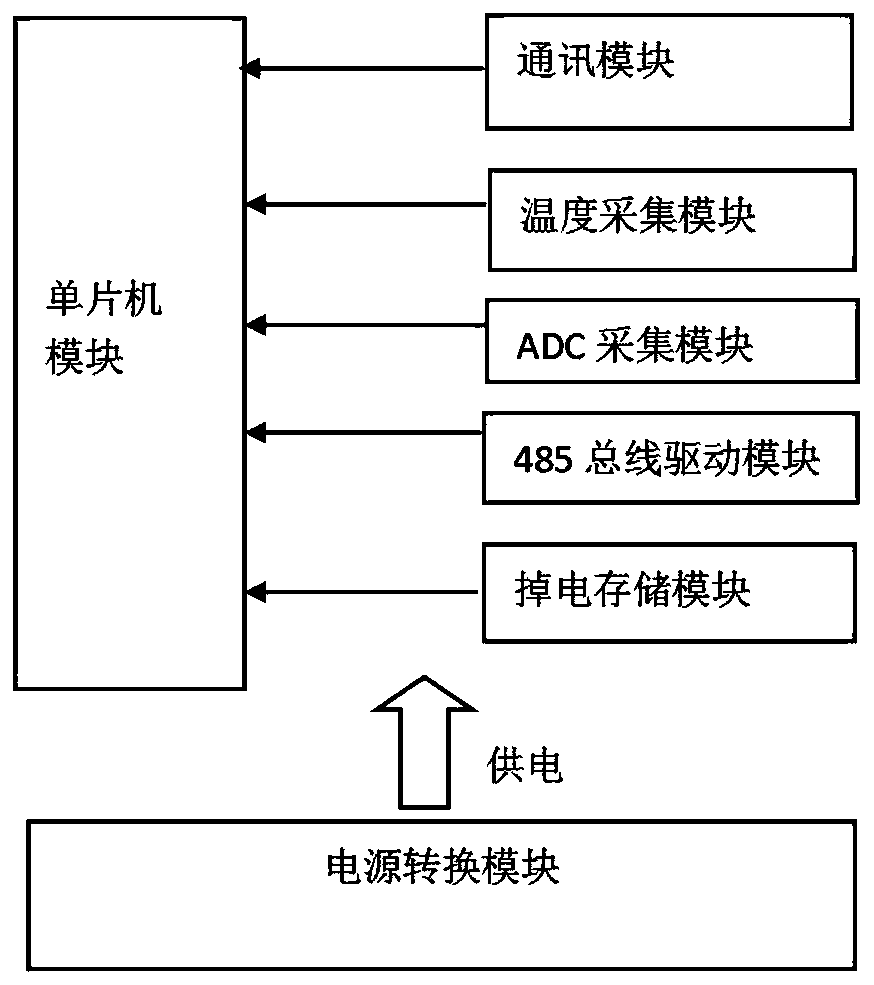

Motor sensor data acquisition unit and method

InactiveCN110597144AReduce the burden onReduce upload bandwidthProgramme controlComputer controlMicrocomputerMicrocontroller

The invention discloses a motor sensor data acquisition unit and method, and the unit comprises a single-chip microcomputer, and a temperature acquisition module, an ADC acquisition module, a 485 busdrive module and a storage module connected to the single-chip microcomputer, wherein the single-chip microcomputer starts a DSP unit, processes the temperature, voltage and current signals collected,removes periodic and sudden interference noise by a filtering algorithm, and identifies the characteristic fault of the motor by a mechanism model algorithm. When a known type is detected, the single-chip microcomputer accelerates the sampling and more accurately identifies fault information. The comprehensive collection of signals about vibration, current and temperature of the motor can determine at the acquisition end that an edge computing has been carried out, without waiting for the network host to issue a command to the bottom to execute. In the field environment where the network bandwidth is not too high, the need for data upload to the network can be reduced to improve the real-time performance of the network. The network can also be prevented from interfering with the scene tocause production accidents when the network is abnormal.

Owner:鞍钢集团自动化有限公司

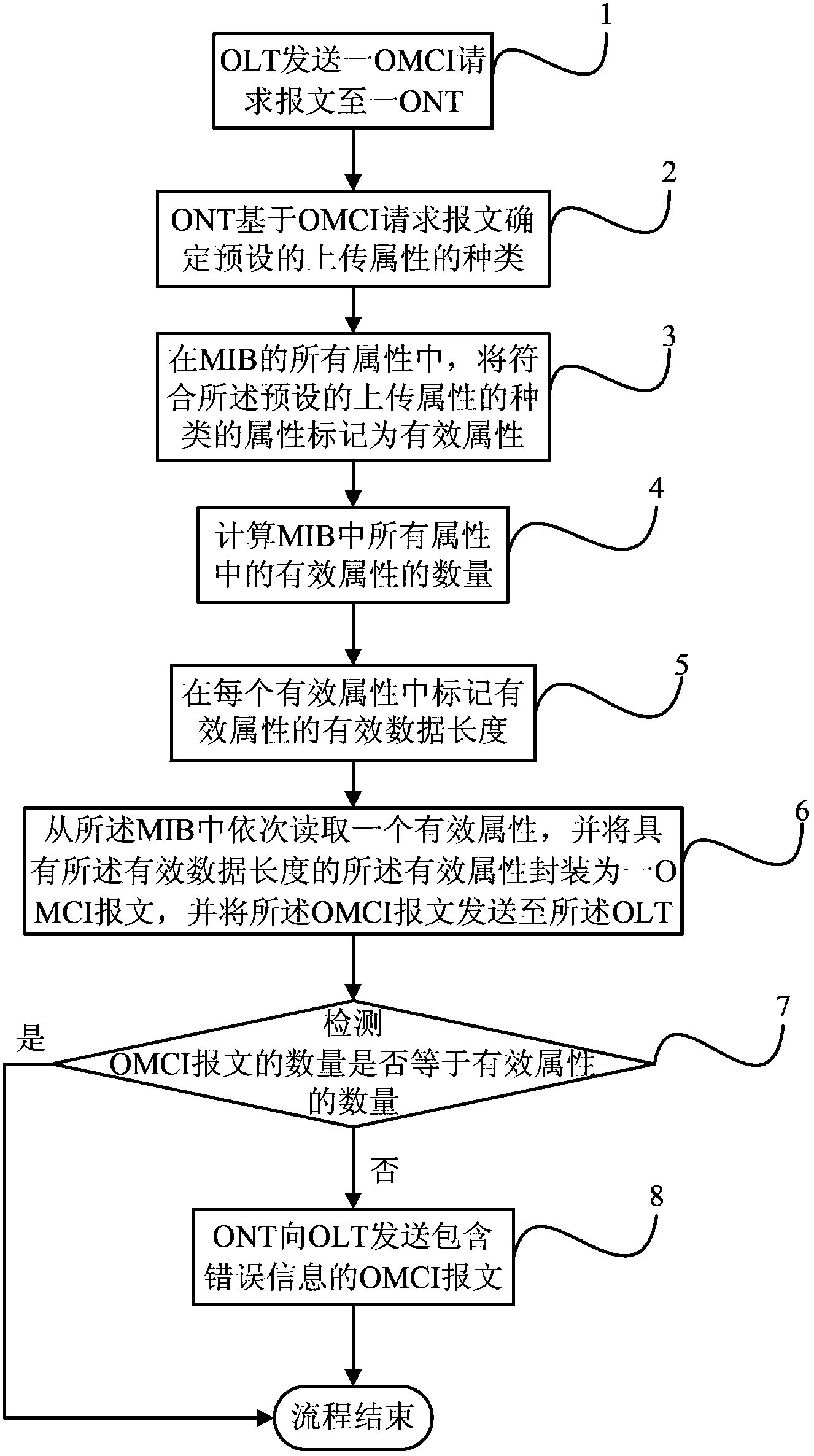

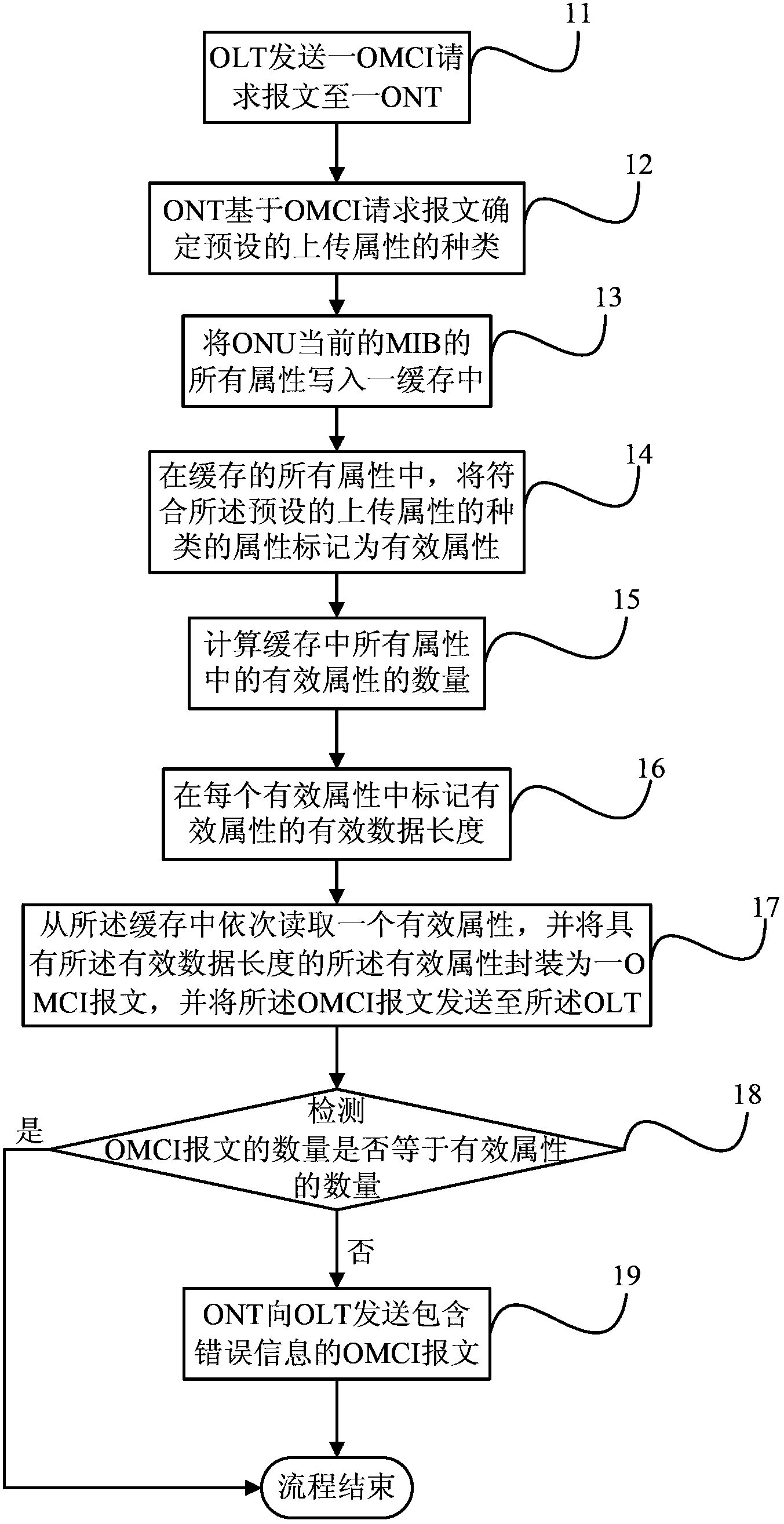

Management Information Base (MIB) data uploading method and Gigabit Passive Optical Network (GPON)

ActiveCN103546230AImprove accuracyReduce uploadMultiplex system selection arrangementsError preventionManagement information baseNetwork termination

The invention discloses a Management Information Base (MIB) data uploading method and a Gigabit Passive Optical Network (GPON). The MIB data uploading method includes: S1 based on varieties of preset uploading attributes, attributes of all attributes in an Optical Network Unit (ONU) or an MIB of an Optical Network Termination (ONT) according with the varieties of the preset uploading attributes are marked as effective attributes; S2 the effective data lengths of the effective attributes are marked sequentially one by one; S3 the effective attributes are read sequentially from the MIB one by one, the effective attributes having the same effective data lengths are packaged to be one OMCI message on the basis of the effective data lengths marked in the effective attributes, and the OMCI message is transmitted to one Optical Line Terminal (OLT). According to the MIB data uploading method, uploading of unnecessary attributes is reduced by marking the effective uploading attributes, a part of system resources is saved, information configuration accuracy is improved, and accordingly the uploading efficiency is improved.

Owner:宋易霄

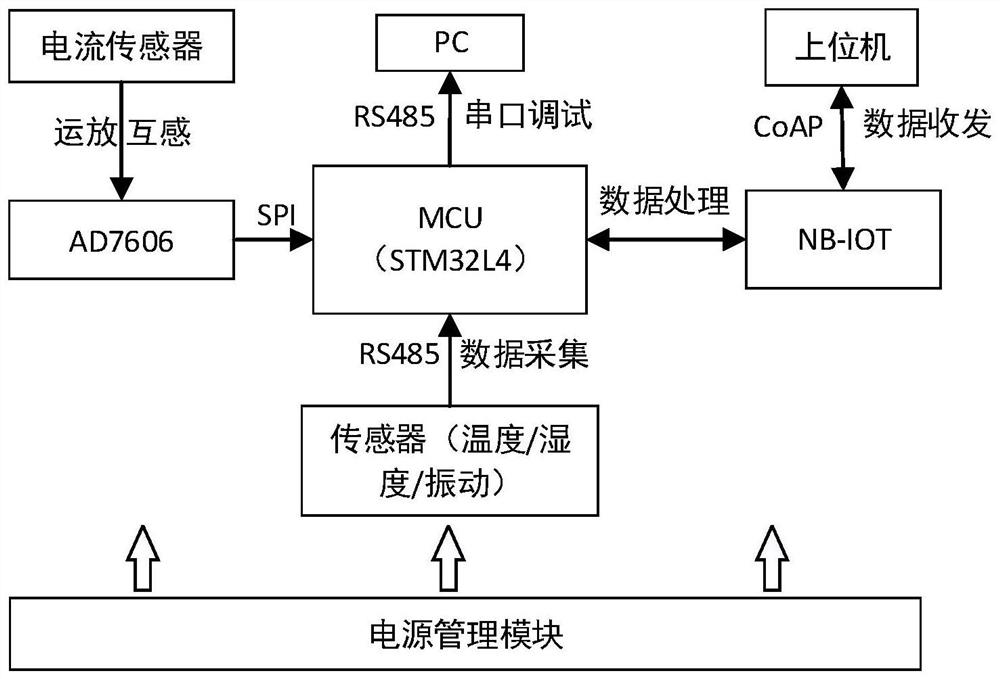

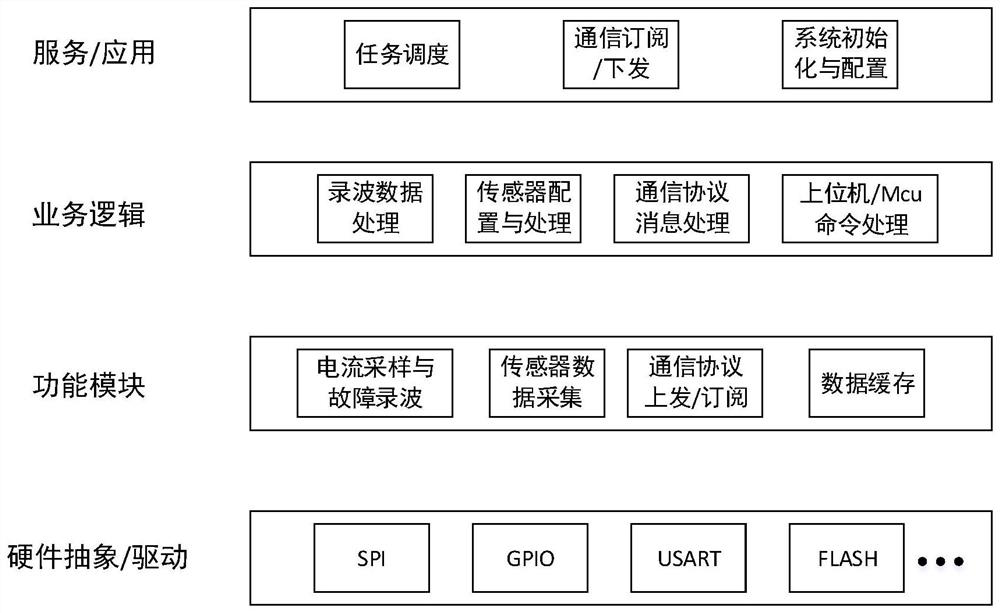

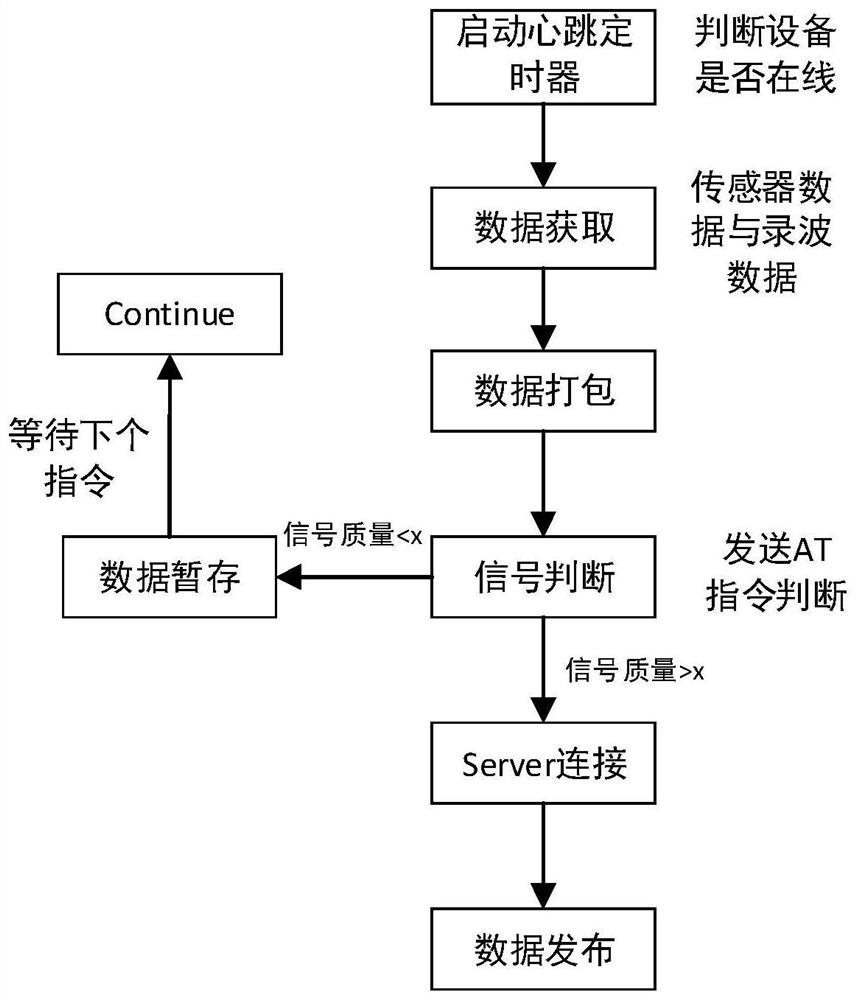

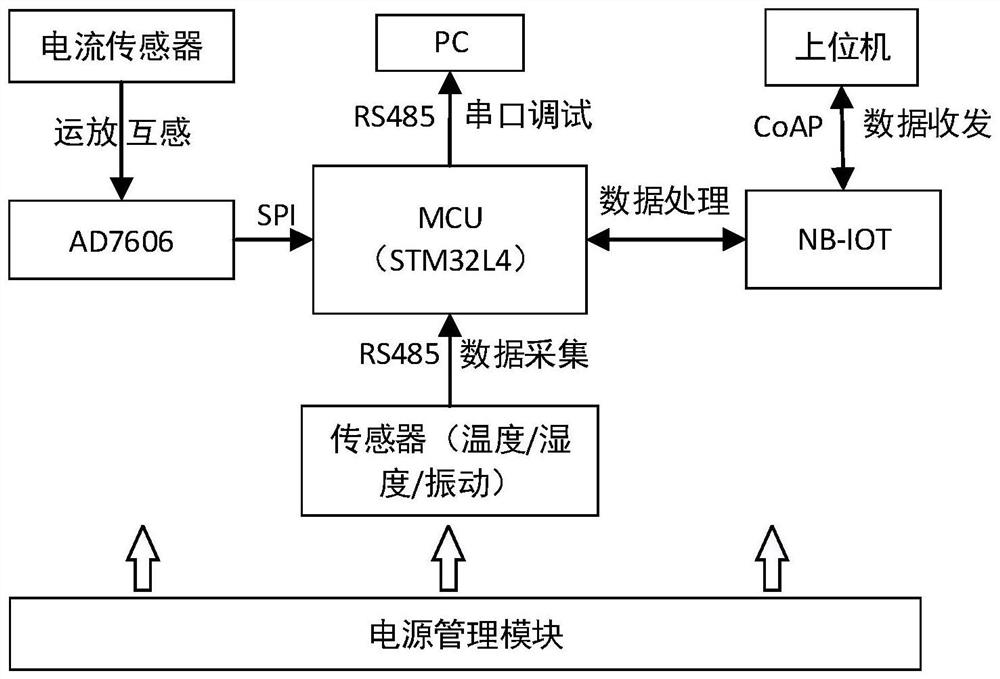

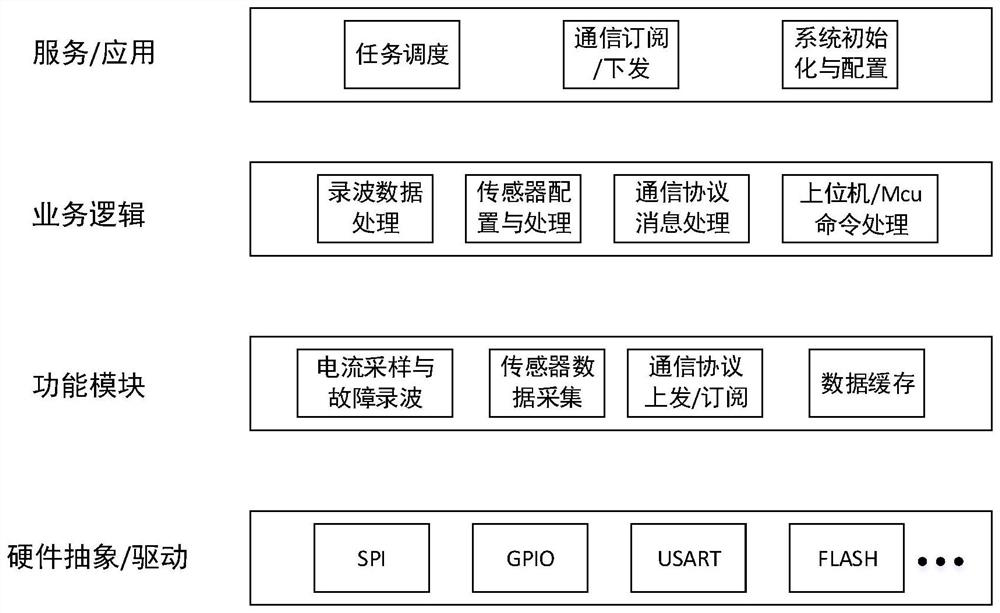

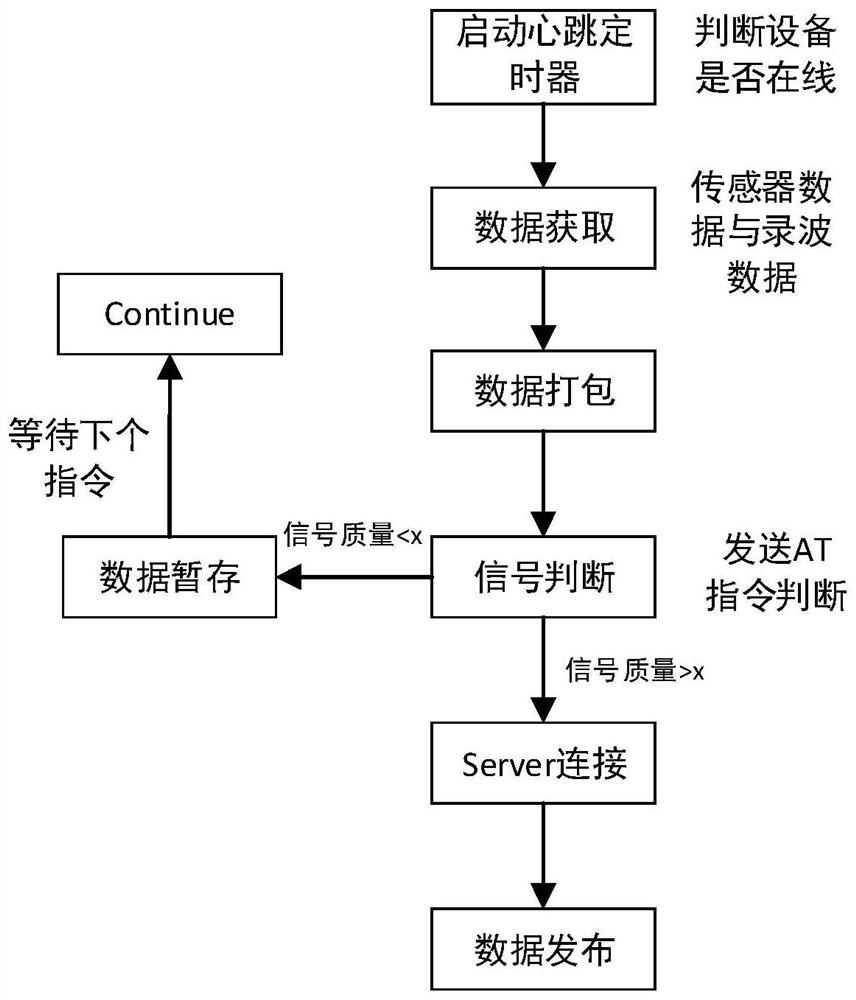

NB-IOT (Narrow Band Internet of Things)-based high-voltage cable low-power-consumption online monitoring equipment

ActiveCN113267707AWide coverageMany connectionsNetwork traffic/resource managementParticular environment based servicesData packCurrent sensor

The invention discloses NB-IOT-based high-voltage cable low-power-consumption online monitoring equipment. The NB-IOT-based low-power-consumption online monitoring equipment comprises a current sensor, an AD conversion module, a main control chip, a PC terminal, an upper computer, an NB-IOT wireless communication module, a sensor group and a power management module. According to the invention, the main control chip carries out priority classification on various required data through equipment working modes, sheath current data and fault recording data are set as a first priority, and the data of the level need to be transmitted in all working modes. Data such as temperature, vibration and equipment information are set as a second priority, and the data of the level can be transmitted only in a normal working mode. In the data transmission process, through the limitation of the sizes of the data packets, the data packets with the too large data size are removed, uploading of invalid data is reduced, in different working modes, the frequency of data communication and the transmission amount of data communication can also be correspondingly changed, communication power consumption is reduced, and normal operation of equipment is also guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

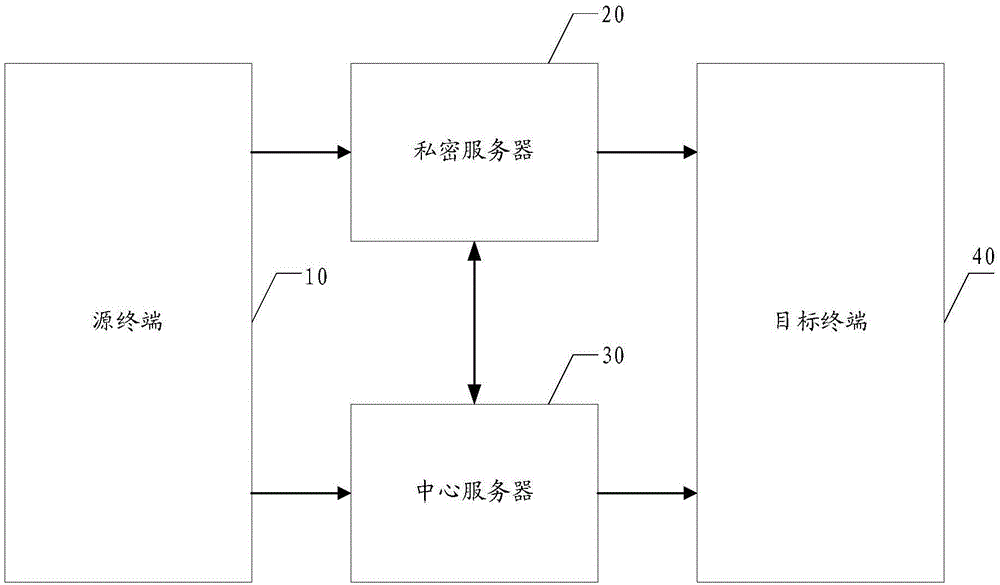

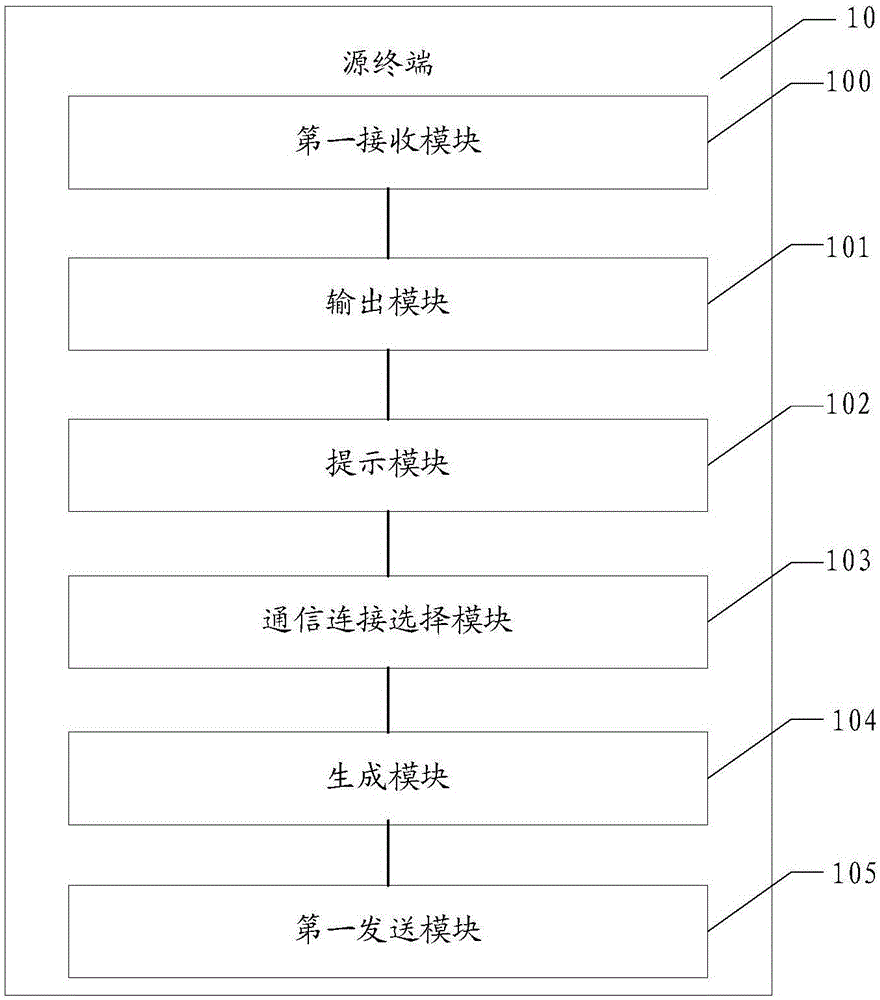

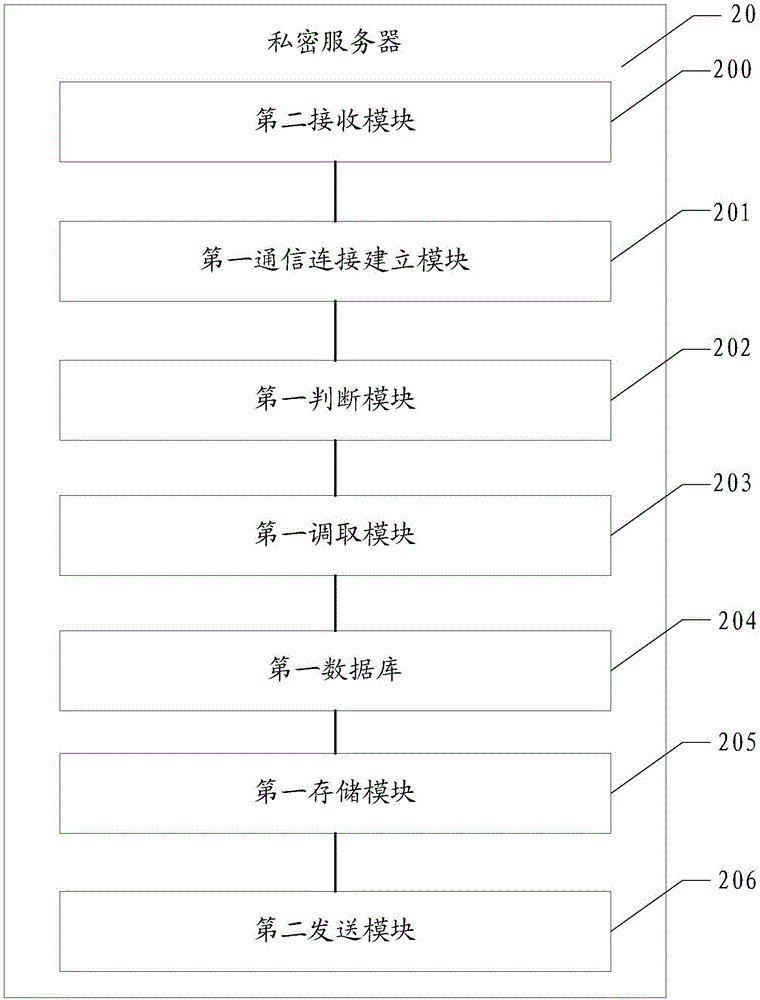

Instant messaging data transmission method and instant messaging data transmission system

InactiveCN105119805AFast data transferFast transmissionData switching networksData transmissionIp address

The invention discloses an instant messaging data transmission method. The instant messaging data transmission method comprises the following steps: a source terminal generates an identification code according to to-be-sent instant messaging information data and a preset rule, the source terminal sends a communication connection request to a private server, the source terminal sends a data transmission request to the private server after communication connection between the source terminal and the private server is established, the private server judges whether identification information consistent with the identification code exists in a first database, the private server calls the instant messaging data corresponding to the identification information from the first database if the identification information consistent with the identification code exists in the first database, and the private server sends the instant messaging data to a target terminal corresponding to IP address information of the target terminal. The invention further discloses an instant messaging data transmission system. When the fact that corresponding instant messaging data exists in the first database is determined through the data transmission request sent by the source terminal, the uploading process of the instant messaging data is reduced, and the data transmission speed is improved.

Owner:深圳市云舒网络技术有限公司

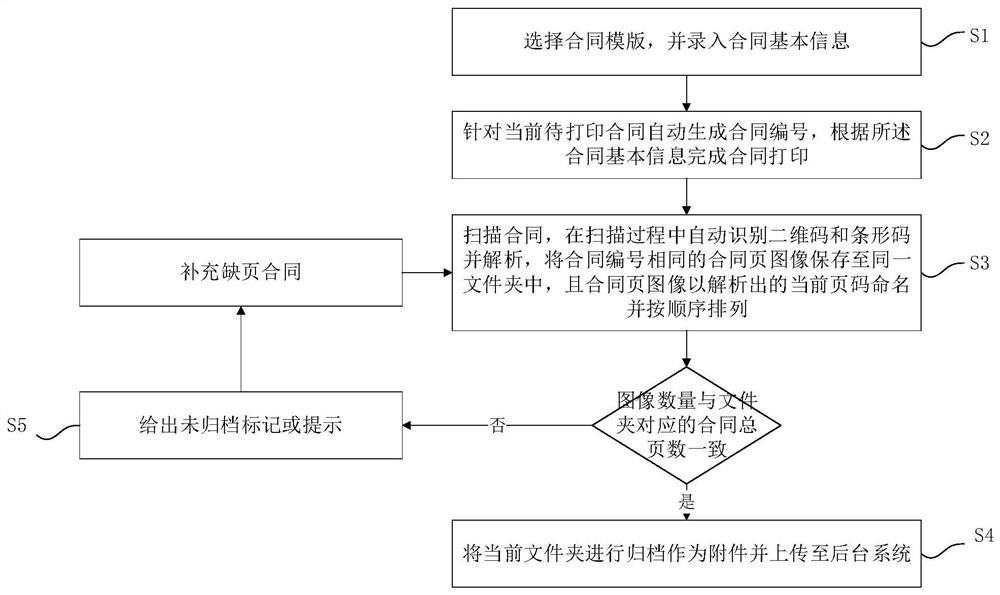

Paper contract management method

ActiveCN112540965AReduce uploadReduce steps to uploadData processing applicationsNatural language data processingHome pageSoftware engineering

The invention is applicable to the technical field of contract management, and provides a paper contract management method, which mainly comprises the steps of information input, contract printing, contract scanning analysis and contract filing, and is characterized in that printed contract pages have bar code information (a home page has a two-dimensional code), and a plurality of printed contracts can be scanned together; images obtained through scanning can be automatically sorted, named and archived, when scanning recognition is correct, accessories can be automatically uploaded, contractscan be inquired and approved in a background system, and the problems that paper contracts are manually uploaded in batches and matched with system data after being uploaded are solved. When contractpages with wrong scanning recognition occur, information can be manually supplemented and then stored in the folder to be uploaded, the problem that automatic uploading cannot be achieved due to thefact that two-dimensional codes or bar codes are not clearly scanned is solved, finally, uploading of all paper contracts is guaranteed, and the paper contracts are electronically managed.

Owner:湖北航天信息技术有限公司

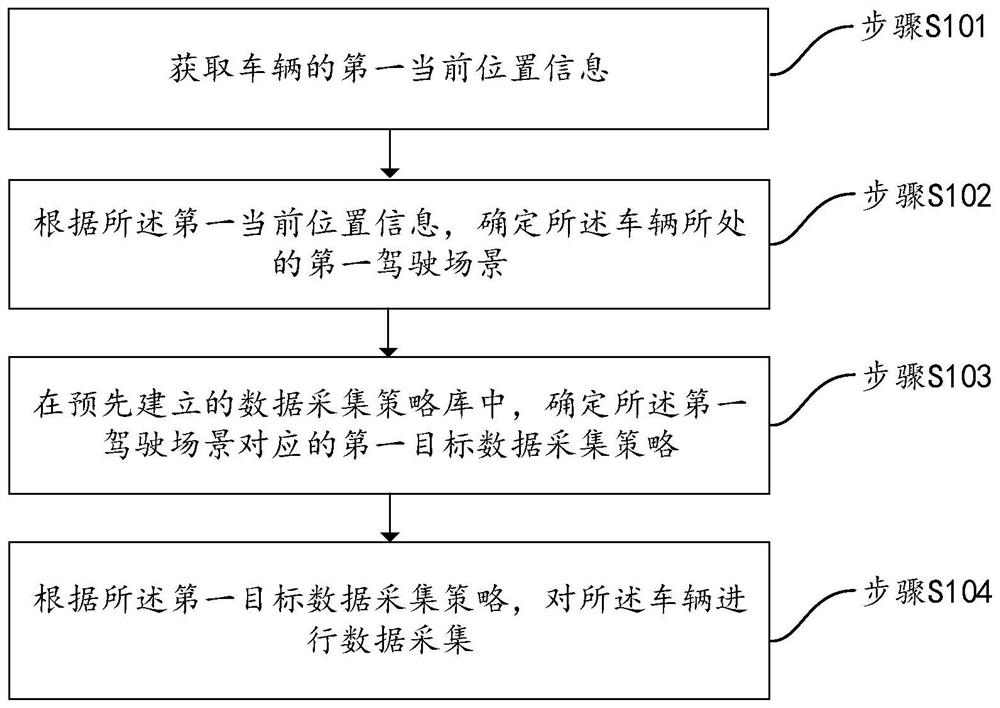

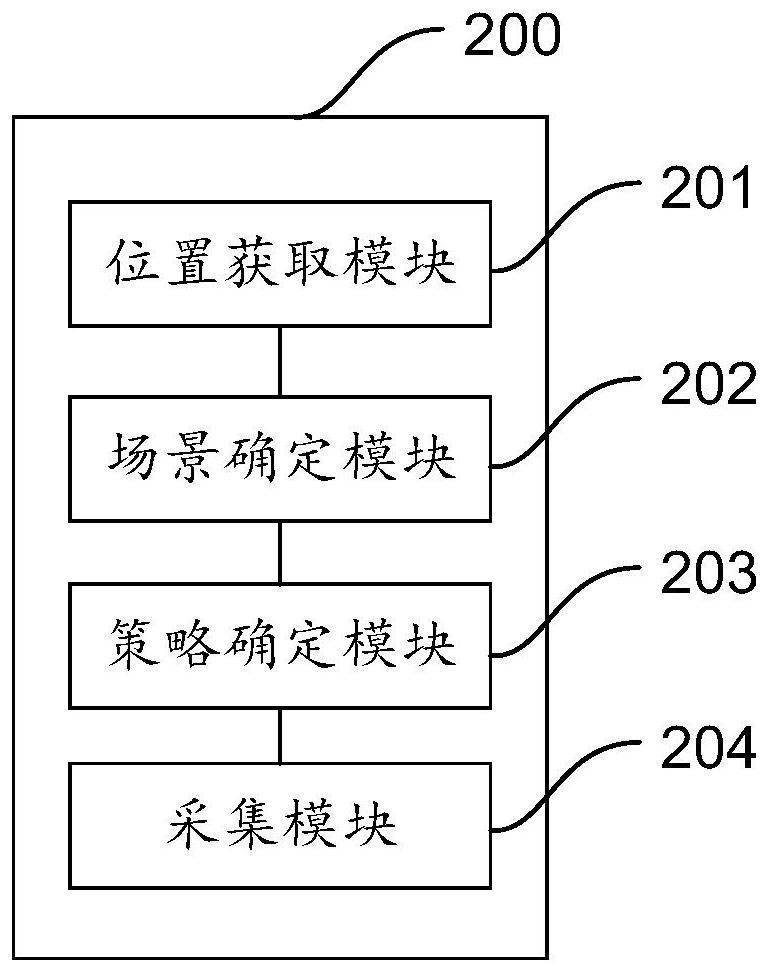

Data acquisition method and device, readable storage medium and vehicle

PendingCN114245303AReduce uploadReduce consumptionTelemetry/telecontrol selection arrangementsNetwork traffic/resource managementIn vehicleScene matching

The invention provides a data acquisition method and device, a readable storage medium and a vehicle, and belongs to the technical field of data processing. The method comprises the steps of determining a first driving scene where a vehicle is located according to first current position information of the vehicle; and determining a first target data acquisition strategy corresponding to the first driving scene in a pre-established data acquisition strategy library, so that the vehicle can perform data acquisition on the vehicle according to the first target data acquisition strategy. According to the embodiment of the invention, the corresponding target data acquisition strategy is matched based on the position information of the vehicle and the corresponding driving scene, and data acquisition is carried out on the vehicle according to the acquisition item in the target data acquisition strategy and the acquisition frequency corresponding to the acquisition item, so that the acquired data volume and the acquisition frequency can be effectively reduced, and on-demand acquisition is realized; therefore, the memory occupation amount is reduced, the CPU load of the vehicle-mounted terminal is reduced, the uploading of redundant data is reduced, and the flow consumption is reduced.

Owner:诺博汽车科技南京有限公司

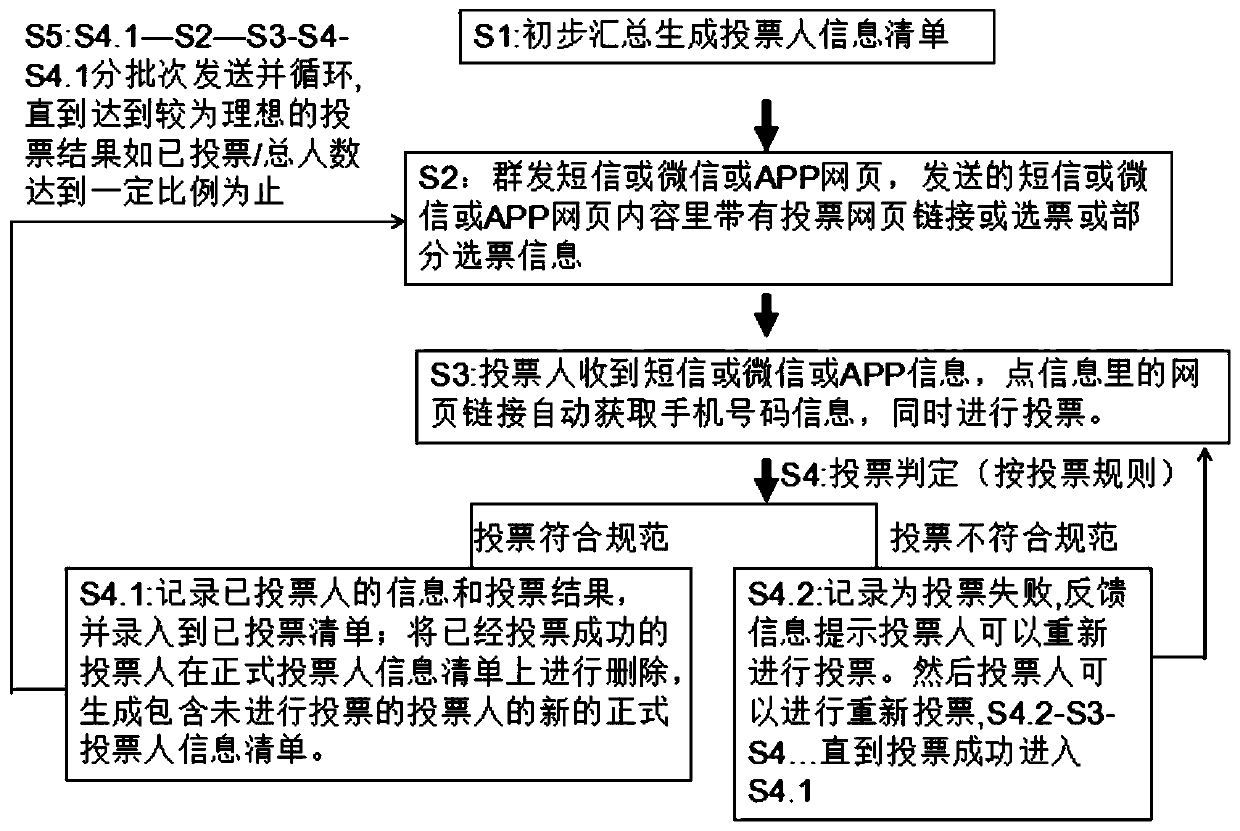

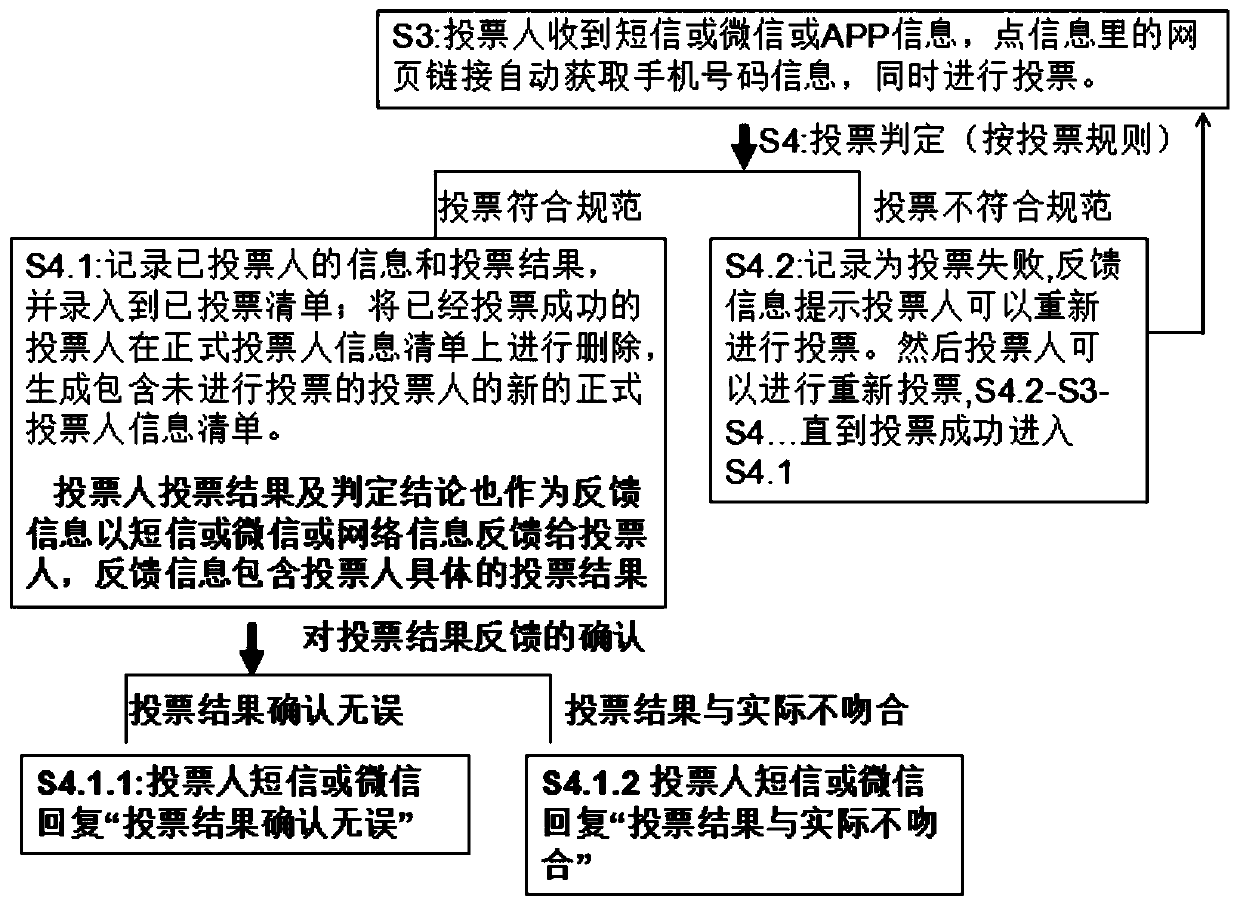

Electronic voting method

PendingCN110189462AEasy to participateShorten the timeVoting apparatusUser verificationComputer science

The invention relates to the field of electronic voting technologies, in particular to an electronic voting method. The method comprises the specific step that S1, a voter information list is generated through preliminary summarization. The application fields of the method include but not limited to house-owner convention voting or other public affair decision-making fields. Through the method, the problems that voting is difficult and electronic voting efficiency is low in public affairs are solved while it is convenient for voters to participate in public affair decision by voting; and sincea network technology carrying voter identity information automatically is applied to electronic voting, voter identities are automatically recognized, the link that mobile phone numbers and verification codes need to be input for user verification on the voter identities in the prior art is omitted, voting efficiency is improved, time is saved for the voters, and the electronic voting method is more advanced.

Owner:合肥诺优信息科技有限公司

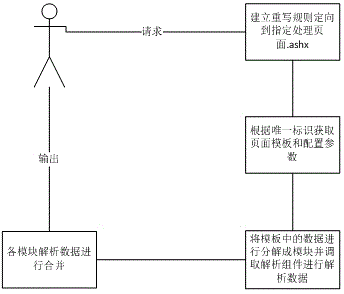

Method for realizing virtualized page

ActiveCN105278924AMeet functional changesRealize unified managementSoftware simulation/interpretation/emulationVirtualizationSystem stability

The invention relates to a method for realizing virtualized pages. The method is characterized by comprising: defining an unique identification UniqueKey for each virtualized page, according to a request sent by a client, obtaining data from Memcached, then determining the data through program codes, if the data is not null, directly outputting the data, if the data is null, performing further processing; then, sending a request through a SOA, according to the unique identifications, obtaining a template of the page from a database, and obtaining data; performing merging processing on the data, according to setting conditions of the page, determining whether the data needs to be stored in the Memcached, returning to the merged data; and finally, a virtualized station receiving the analyzed merged data, and outputting the data to the client. Thus, automation operation is realized to the maximum extent, and manpower cost for project maintenance is reduced. The method satisfies function modification of the virtualized page, and rapidly brings new pages online. Uploading of a server is reduced, and system stability is improved, and unified management of the virtualized pages can be effectively satisfied.

Owner:同程大唐汇智网络科技南京有限公司

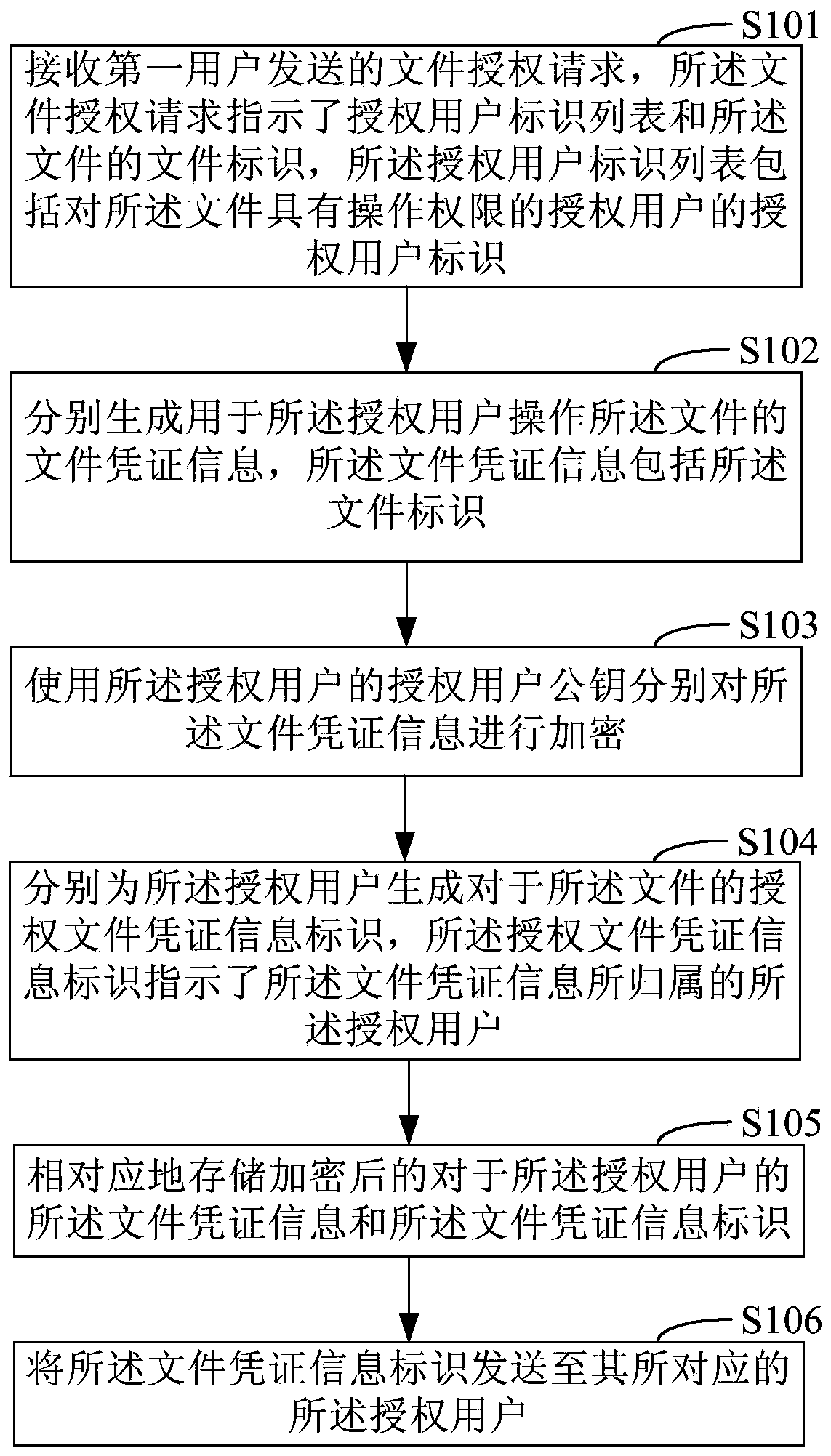

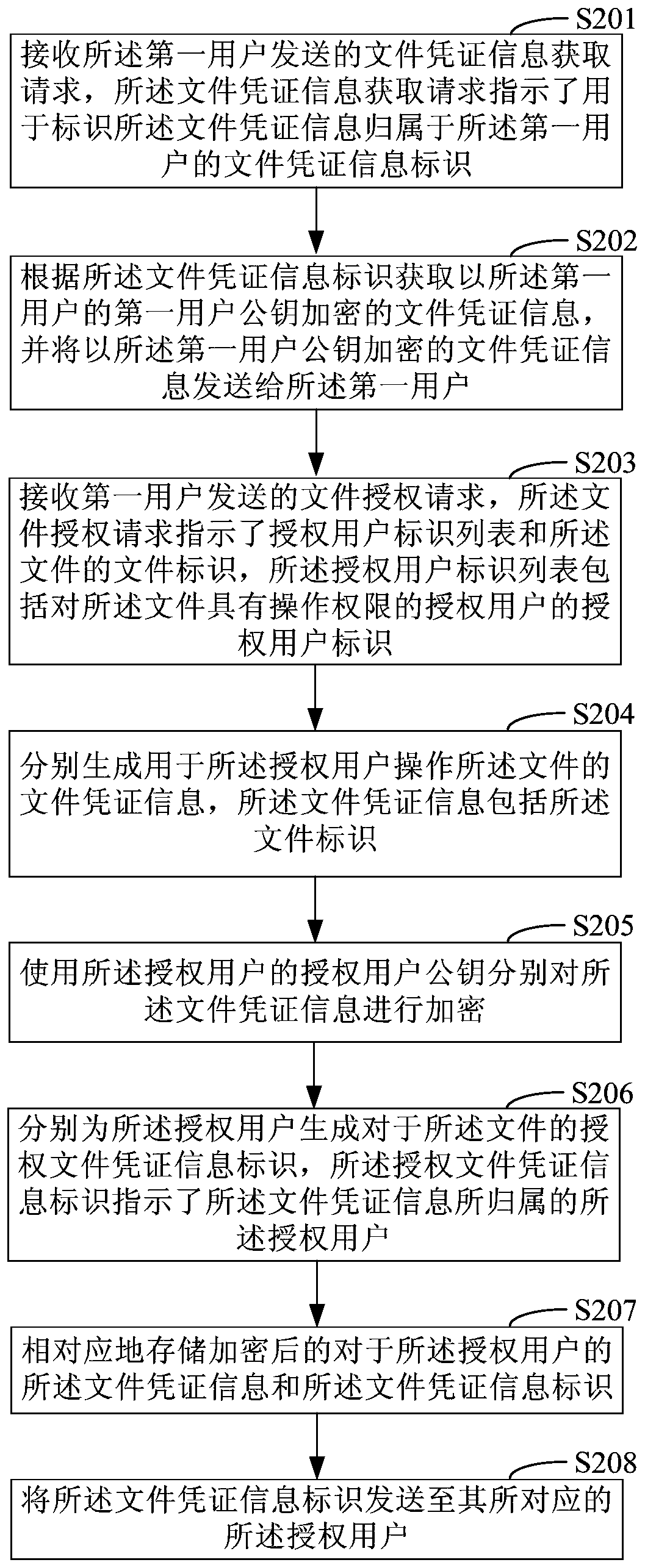

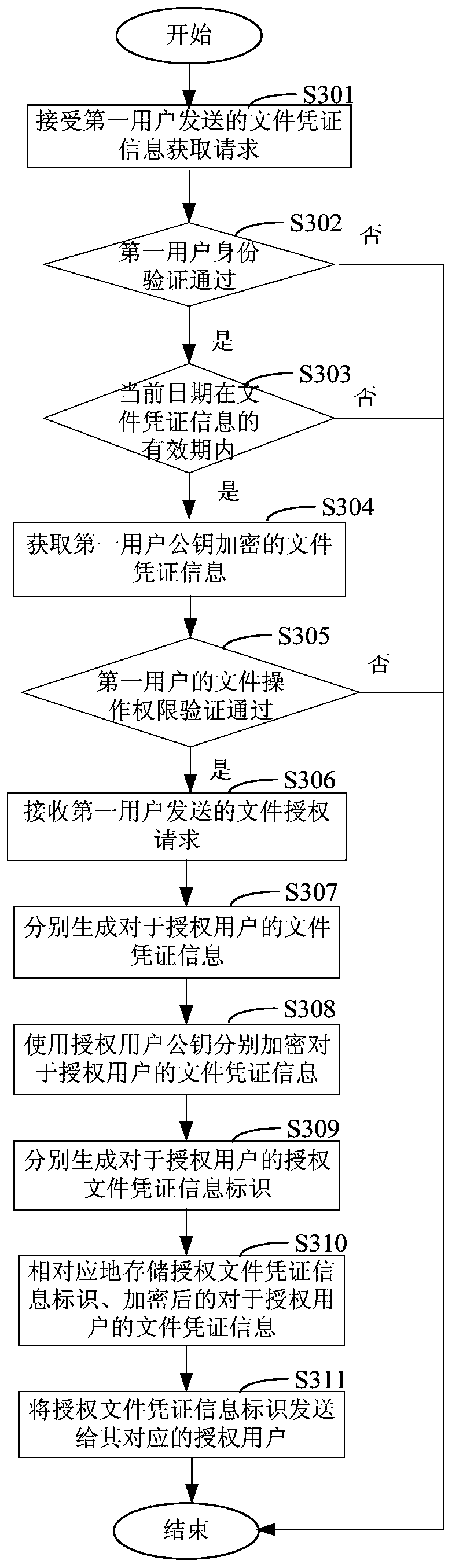

File authorization access method, device and system based on file certificate information

The invention discloses a file authorization access method, device and system based on file certificate information, and relates to the technical field of computers. The specific embodiment of the method comprises the following steps: receiving a file authorization request sent by a first user; respectively generating file certificate information for the authorized user to operate the file; respectively encrypting the file certificate information by using an authorized user public key of the authorized user; forming authorization file certificate information identifiers for the files for the authorization users respectively; correspondingly storing the encrypted file voucher information and the encrypted file voucher information identifier for the authorized user; and sending the file certificate information identifier to the corresponding authorized user. According to the embodiment, the file stream frequency is reduced, and the consumption of network resources is reduced.

Owner:THE PEOPLES BANK OF CHINA DIGITAL CURRENCY INST

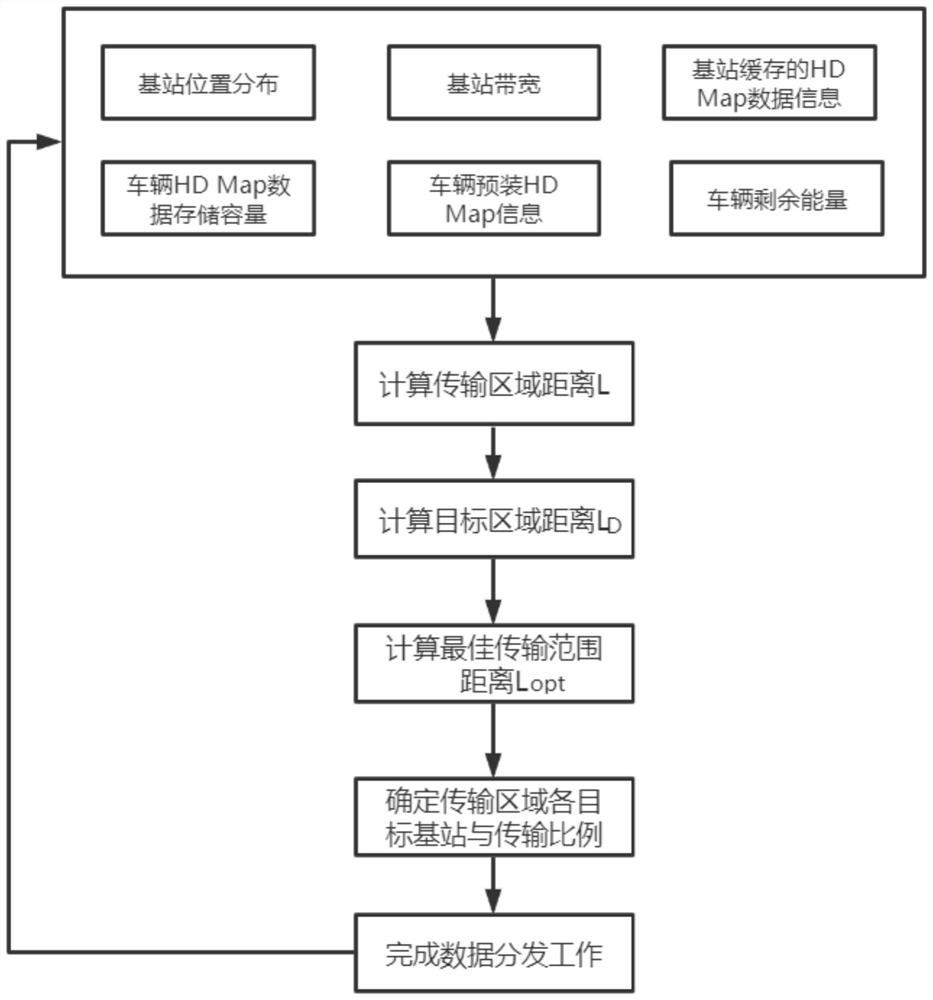

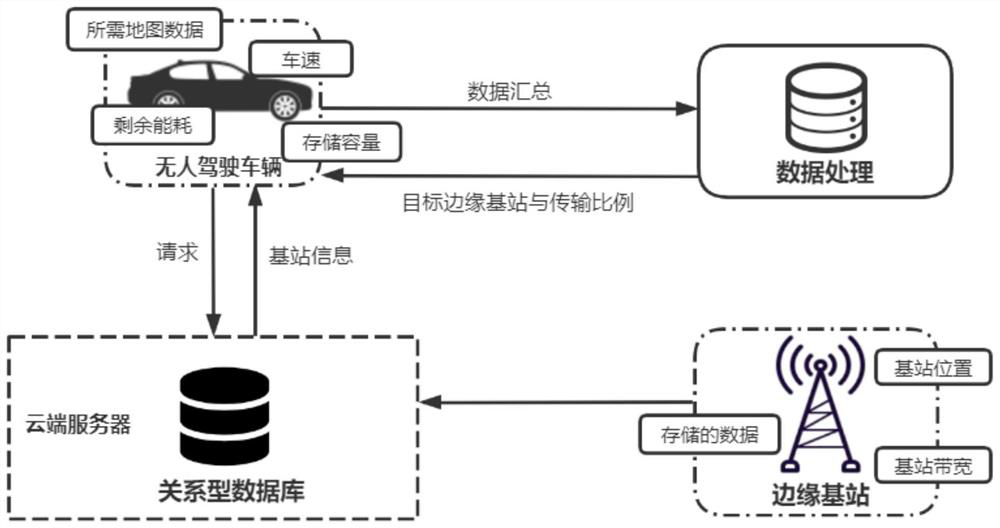

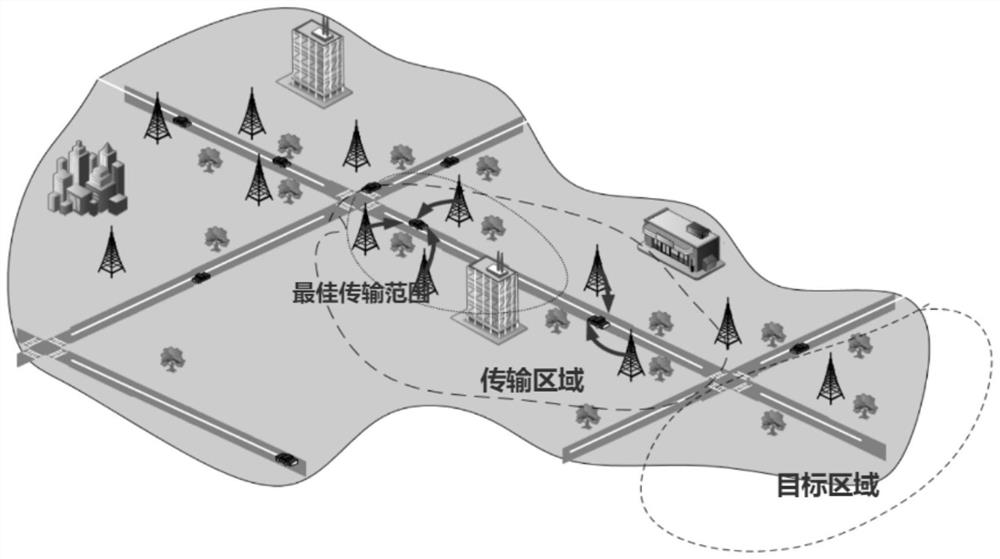

Unmanned HD Map data distribution method based on energy consumption

ActiveCN112908011AReduce upload and download timesReduce data transfer timeDetection of traffic movementData transmissionData information

The invention discloses an unmanned HD Map data distribution method based on energy consumption, and the method comprises the steps that 1), an unmanned vehicle obtains edge base station information from a cloud server, wherein the edge base station information comprises an edge base station ID, an edge base station position distribution condition, an edge base station bandwidth and HD Map data information cached by an edge base station; (2) the unmanned vehicle obtains data information of the unmanned vehicle, wherein the data information comprises HD Map data storage capacity, pre-installed HD Map information and residual energy; 3) a transmission area distance L and a target area distance LD are calculated; 4) an optimal transmission range distance Lopt is calculated; and 5) the unmanned vehicle determines all target edge base stations and the respective data transmission ratios in the transmission area, and then completes the data distribution work. According to the invention, the required HD Map data information can be transmitted within the minimum transmission time under the condition that the energy consumption of the unmanned vehicle is limited.

Owner:SOUTH CHINA UNIV OF TECH

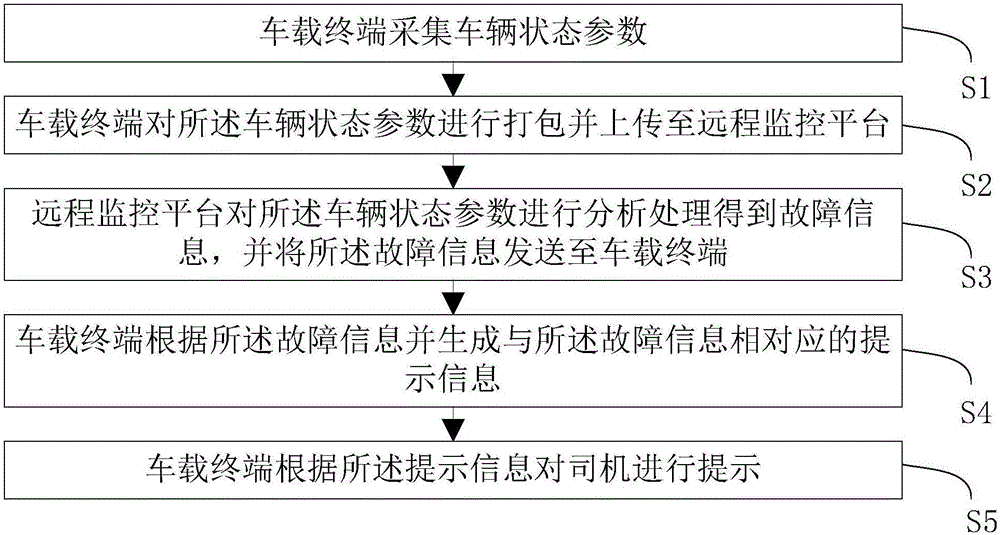

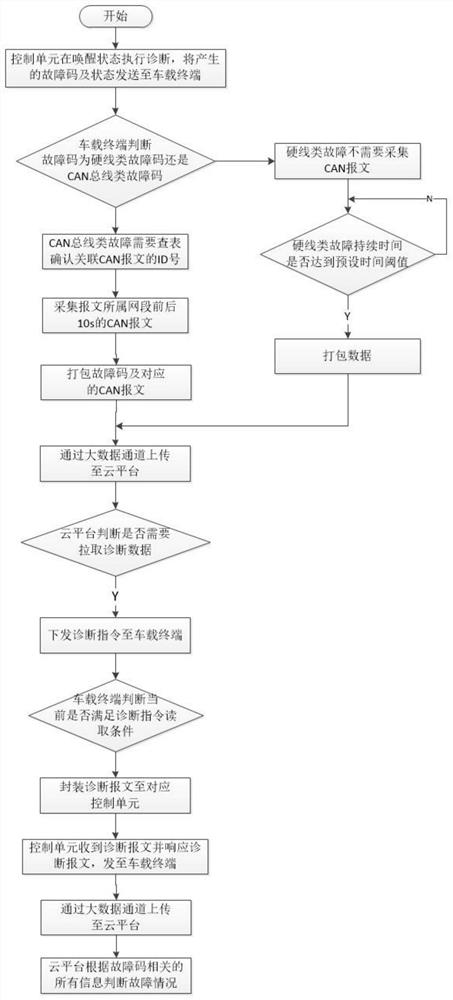

Vehicle fault online diagnosis method and system

PendingCN114839949ASave data processing and storage spaceImprove trustProgramme controlElectric testing/monitoringEmbedded systemIn vehicle

The invention relates to a vehicle fault on-line diagnosis method and system, and the method comprises the steps: a control unit executes self-diagnosis, converts a fault code and a fault code state into a CAN message, and transmits the CAN message to a vehicle-mounted terminal if the fault code is generated or the fault code state is changed; the vehicle-mounted terminal judges whether the fault code is a hard wire type fault code or a CAN bus type fault code, if the fault code is a hard wire type fault, the CAN message associated with the fault code is not collected, whether the duration of the hard wire type fault reaches a preset time threshold value or not is continuously judged, and if yes, the vehicle-mounted terminal packs the fault code and uploads the packed fault code to the cloud platform. After the whole vehicle fault code is reported on line, the fault code can be accurately and comprehensively analyzed, the real situation of the fault can be systematically approved, then an early warning prompt is given to a vehicle owner, and through the process, the sense of confidence of the vehicle owner is effectively improved.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

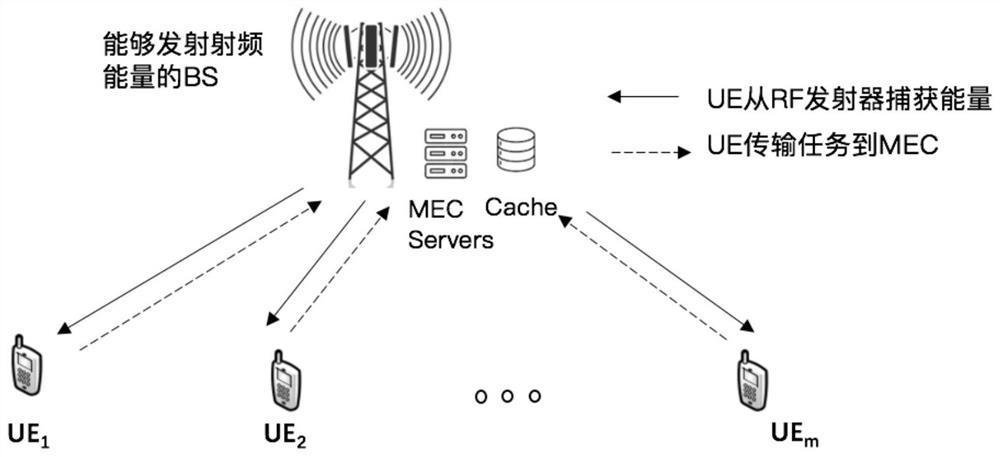

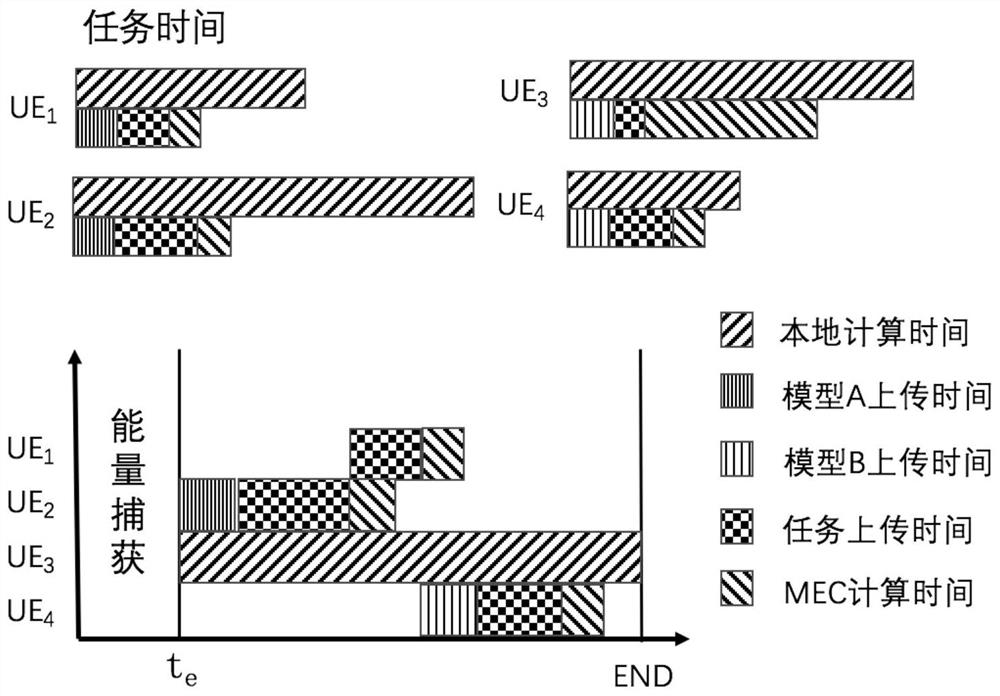

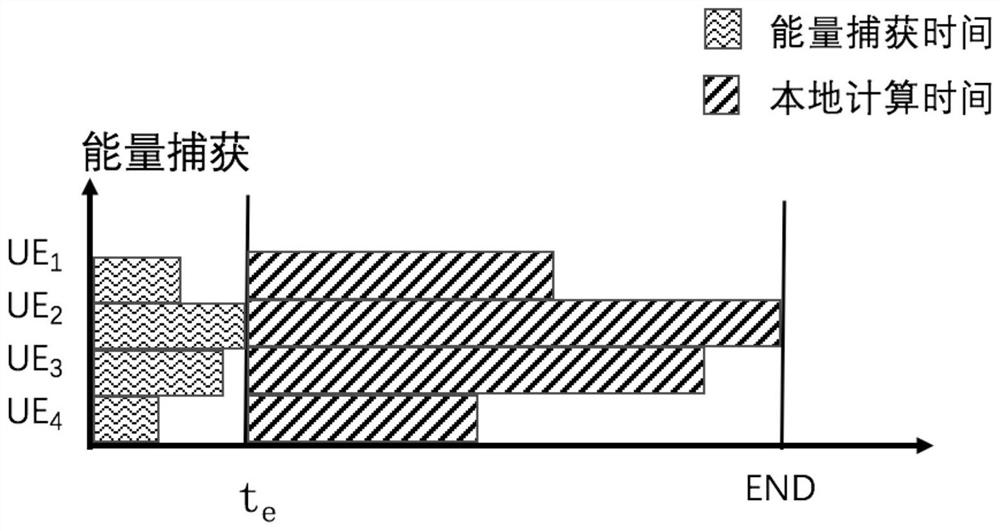

Task calculation unloading decision and scheduling method for energy capture network model

PendingCN112231009AShorten the timeIn line with the concept of green environmental protectionPower managementProgram initiation/switchingAlgorithmGenetics algorithms

The invention discloses a task calculation unloading decision and scheduling method for an energy capture network model. The method comprises the following steps of: counting a task generation type and a specific calculation amount; enabling the user equipment to capture energy in a unified manner; reasonably utilizing a Cache model to carry out calculation unloading; dynamically adjusting a modelin the Cache; determining a target function and a limiting condition, and establishing a problem model; and solving the mathematical problem with hybrid discrete continuous optimization by adopting an LRU replacement algorithm and a genetic algorithm so as to obtain an unloading decision of task calculation and a task unloading sequence. According to the invention, a reasonable task scheduling scheme is realized, and the speed of completing all calculation tasks can be effectively improved.

Owner:ZHEJIANG UNIV OF TECH

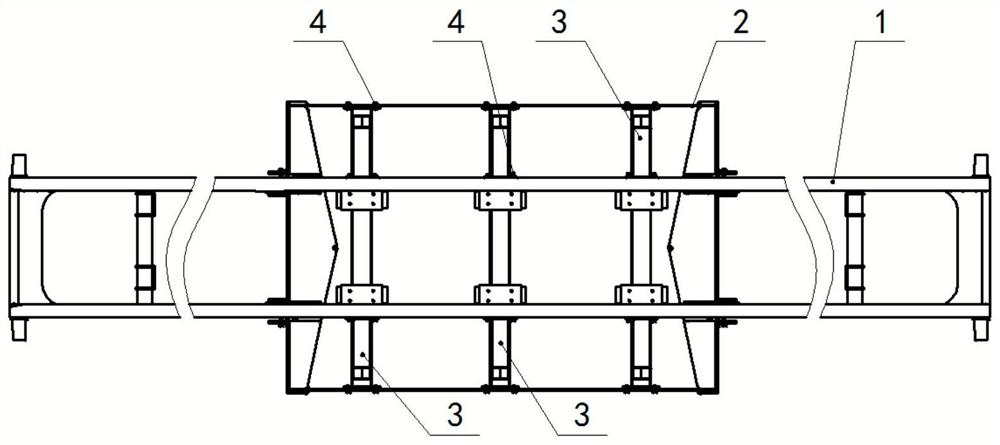

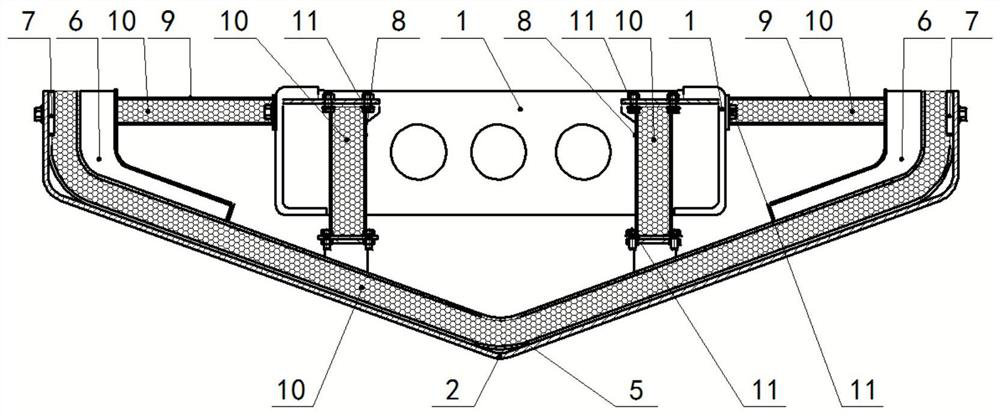

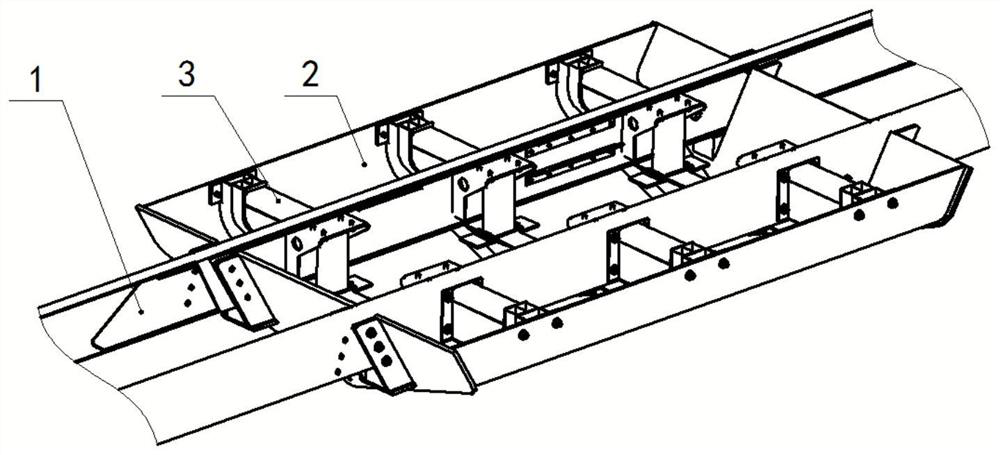

Anti-explosion impact crushing energy-absorbing beam at bottom of vehicle

An anti-explosion impact crushing energy-absorption beam at the bottom of a vehicle (3) comprises a front beam (5), a side beam (6), an installation support (7), a front beam crushing energy absorption box (8), a side beam crushing energy absorption box (9), foamed aluminum (10) and a bolt b (11). The anti-explosion impact crushing energy-absorption beam is characterized in that the front beam (5)is preferably an aluminum alloy rectangular bent pipe beam, is filled with foamed aluminum, is in contact with the bottom armor, plays a role in deforming the bottom armor and absorbing part of explosion impact energy to crush the energy-absorbing beams (3), and is mounted on the chassis girder (1) through bolts a (4) and uniformly distributed; when a vehicle is exploded, the multi-stage buffering and crushing energy absorption effects can be generated, most of energy acting on the bottom lightning protection armor is absorbed, and uploading of the energy is reduced; and the strain of the bottom armor is reduced, so that the lightning protection performance of the vehicle is improved, and finally the effects of protecting passengers and improving the survival rate of the passengers are achieved.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

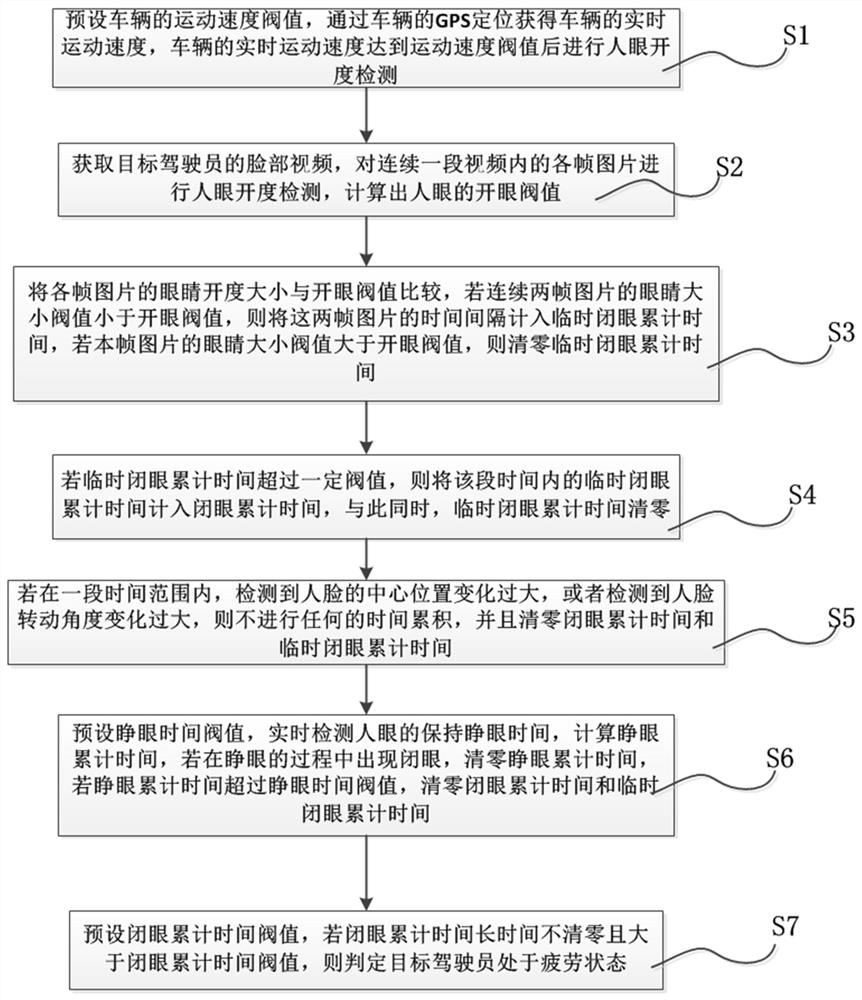

MDVR equipment integrated fatigue detection method of motorcade management platform

ActiveCN111784973AImprove accuracyReduce uploadCharacter and pattern recognitionAlarmsDriver/operatorOphthalmology

The invention discloses an MDVR equipment integrated fatigue detection method of a motorcade management platform. The method comprises: when the real-time movement speed of the vehicle exceeds a movement speed threshold value, carrying out human eye opening degree detection, counting the temporary eye closing cumulative time according to the condition that the eye opening degrees of two continuousframes of human eyes are smaller than an eye opening threshold value, and counting the eye closing cumulative time when the temporary eye closing cumulative time exceeds a certain threshold value, soas to reduce continuous intermittent misjudgment caused by a bad optical environment; when it is detected that the cumulative opening time of the human eyes exceeds an eye opening time threshold value, the cumulative eye closing time can be reset if the rotation angle and the shaking amplitude of the face recognition face are too large, the cumulative eye opening time needing to be reset within continuous time periods, otherwise, the cumulative eye opening time needing to be reset, and therefore the possibility of resetting the cumulative eye closing time by mistake is extremely low. As longas the eye closing cumulative time exceeds the eye closing cumulative time threshold value, the target driver is judged to be in the fatigue state, and the number of wrong alarms is greatly reduced.

Owner:广州敏视数码科技有限公司

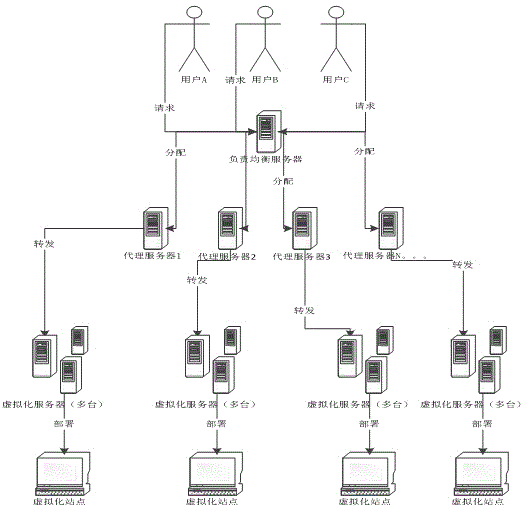

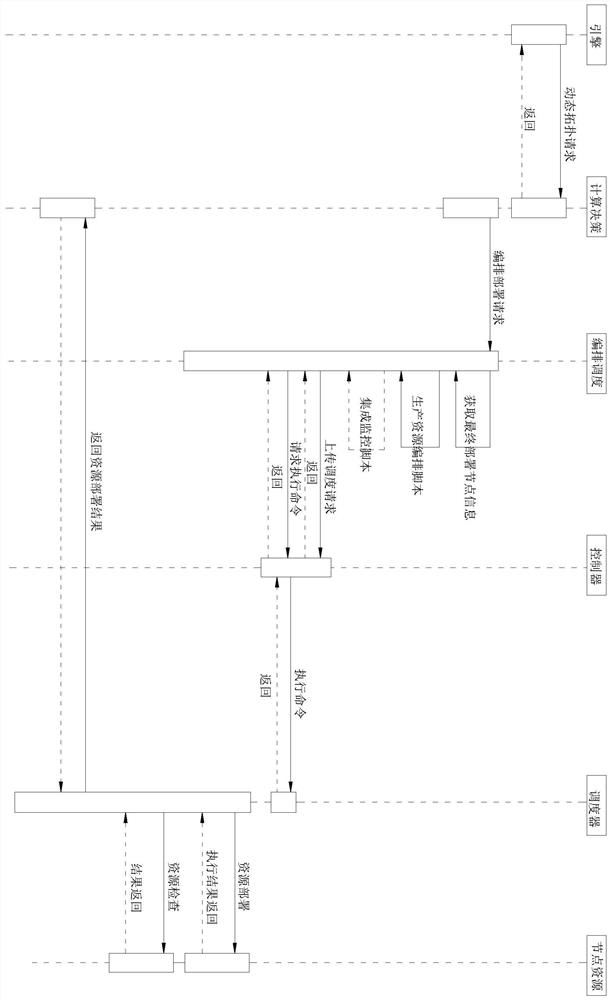

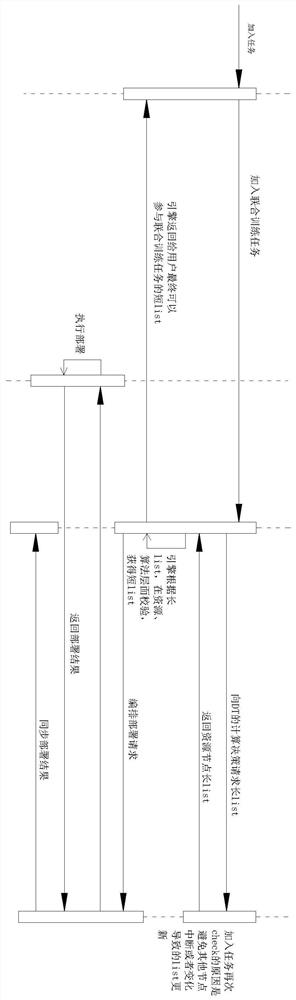

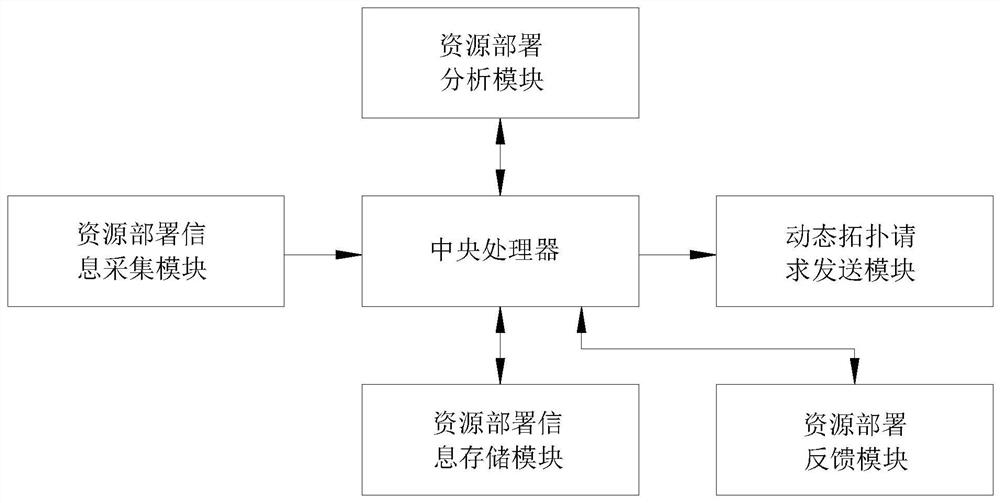

Agent startup deployment system based on cloud platform computing decision

PendingCN114844783AReduce uploadRelieve pressureDatabase updatingTransmissionDecision systemTopology information

The invention discloses an agent start deployment system based on cloud platform computing decision, which comprises an engine, a computing decision system, an arrangement scheduling system, a controller, a scheduler and a node resource, and is characterized in that the engine is interconnected with the computing decision system, the computing decision system is interconnected with the arrangement scheduling system, and the arrangement scheduling system is interconnected with the controller; the controller is interconnected with the scheduler, and the scheduler is interconnected with the node resources. According to the agent starting deployment system based on the cloud platform calculation decision, the dynamic topology is preprocessed before deployment, uploading of junk information is greatly reduced, the system pressure is reduced, meanwhile, the dynamic topology information is dispatched to the corresponding data nodes after decision analysis and arrangement, deployment is reasonable, and retrieval and browsing are convenient.

Owner:新智云数据服务有限公司

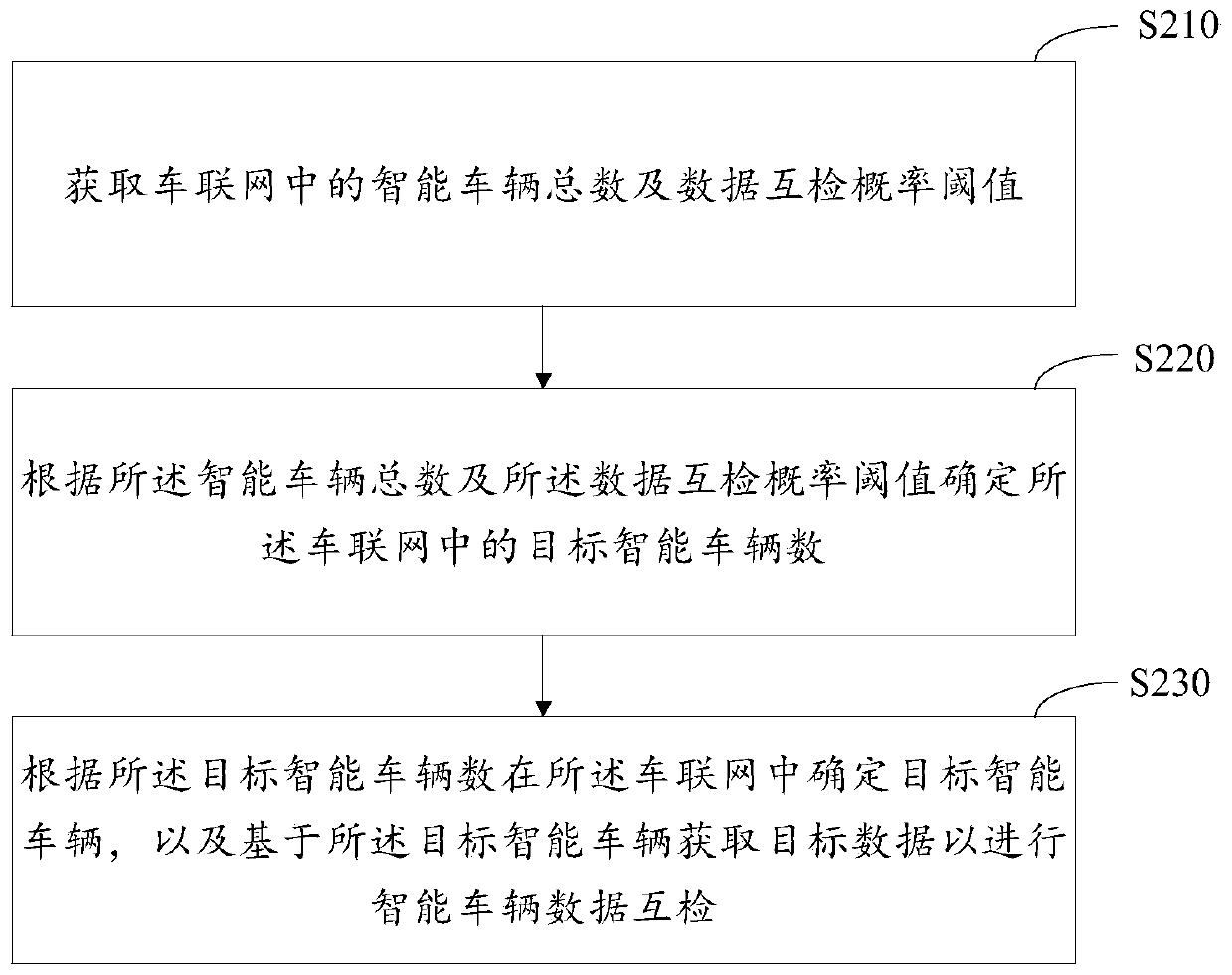

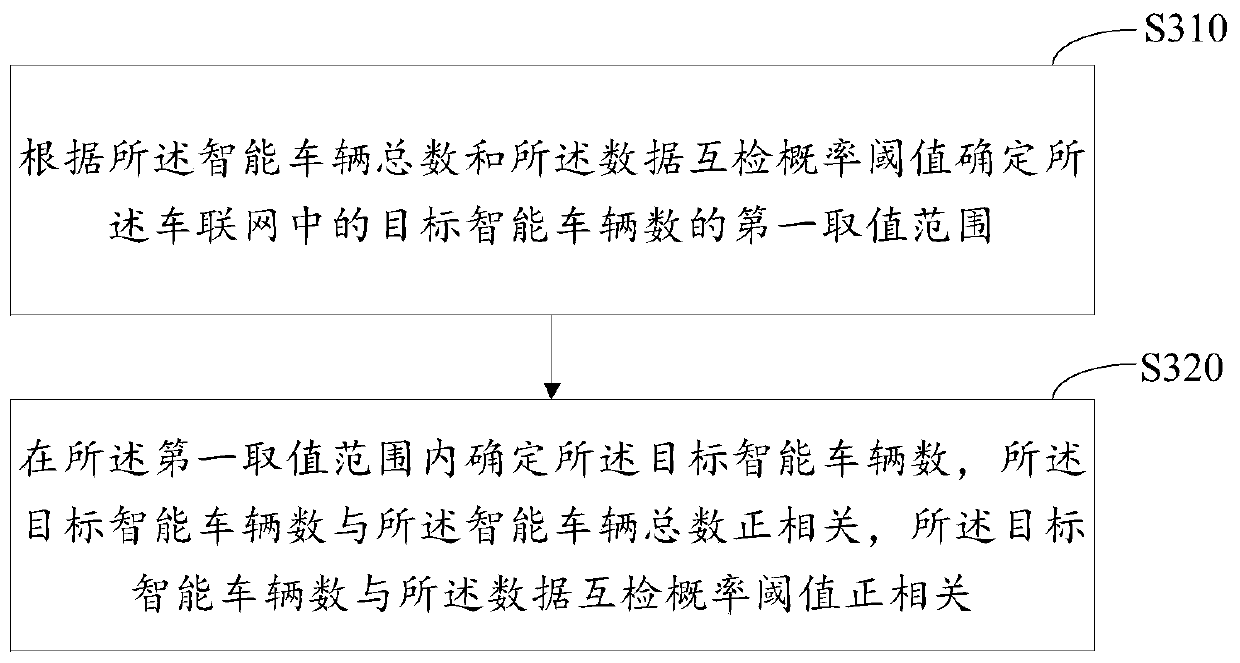

Intelligent vehicle data mutual inspection method and device

ActiveCN111050299AReduce wasteIncrease profitParticular environment based servicesDetection of traffic movementInternet trafficReliability engineering

The embodiment of the invention provides an intelligent vehicle data mutual inspection method and device. The intelligent vehicle data mutual inspection method comprises the steps that the total number of intelligent vehicles in the Internet of Vehicles and a data mutual inspection probability threshold value are acquired; determining the number of target intelligent vehicles in the Internet of Vehicles according to the total number of the intelligent vehicles and the data mutual inspection probability threshold; and determining a target intelligent vehicle in the Internet of Vehicles according to the target intelligent vehicle number, and obtaining target data based on the target intelligent vehicle to perform intelligent vehicle data mutual inspection. According to the technical scheme of the embodiment of the invention, the data uploaded by the intelligent vehicle in the Internet of Vehicles can be mutually checked, the waste of network traffic is reduced, and the utilization rate of the network traffic in the Internet of Vehicles is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

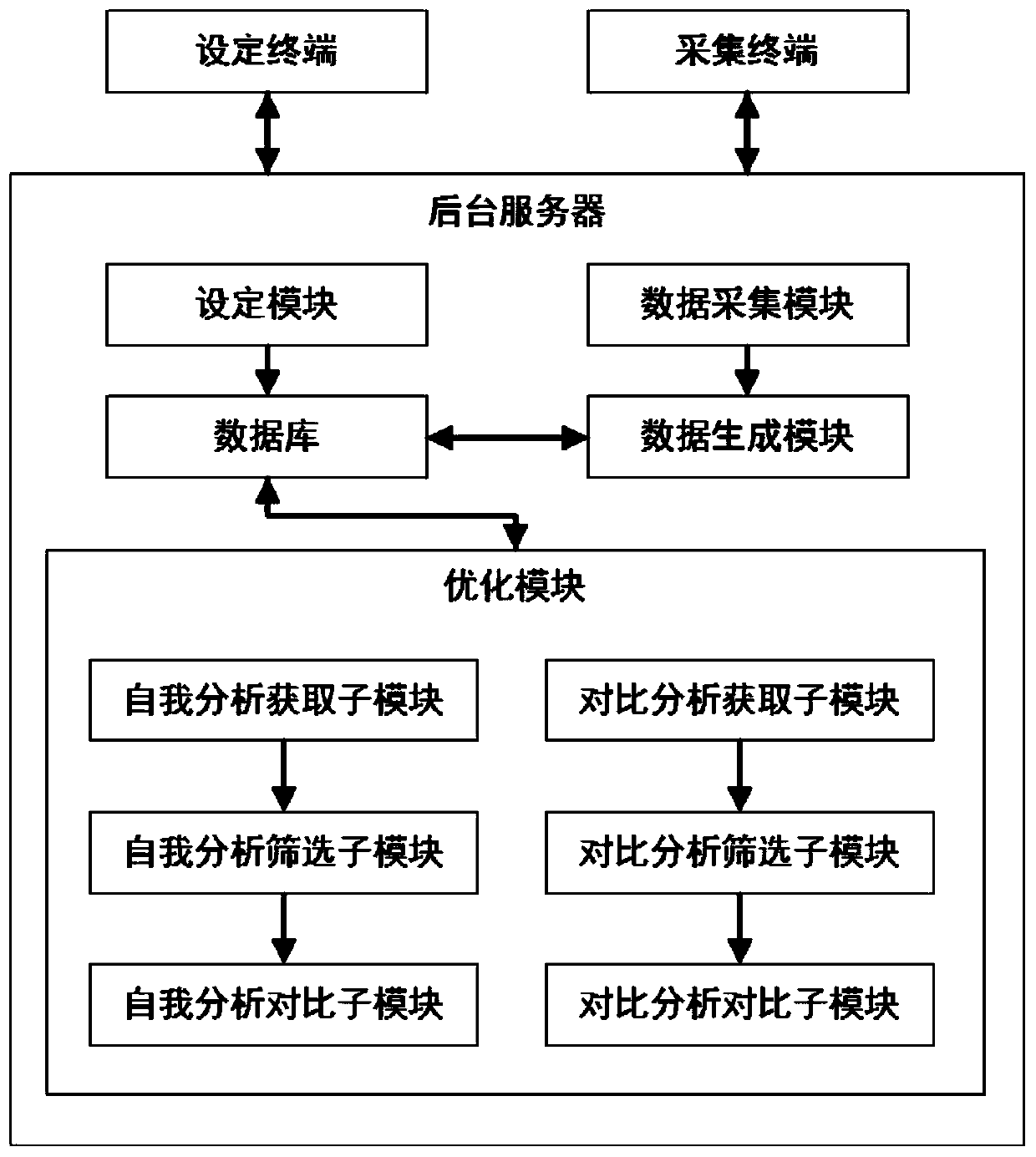

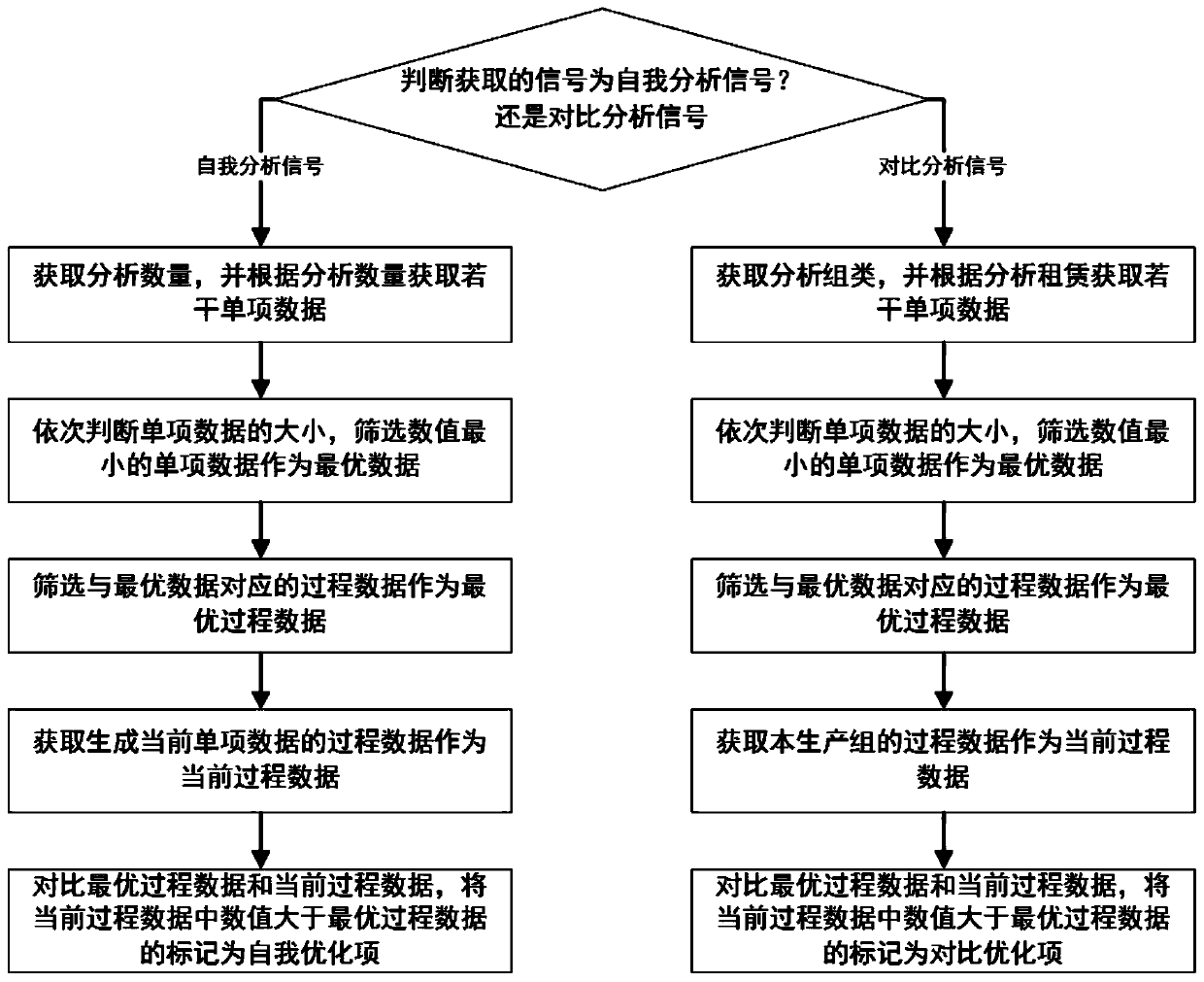

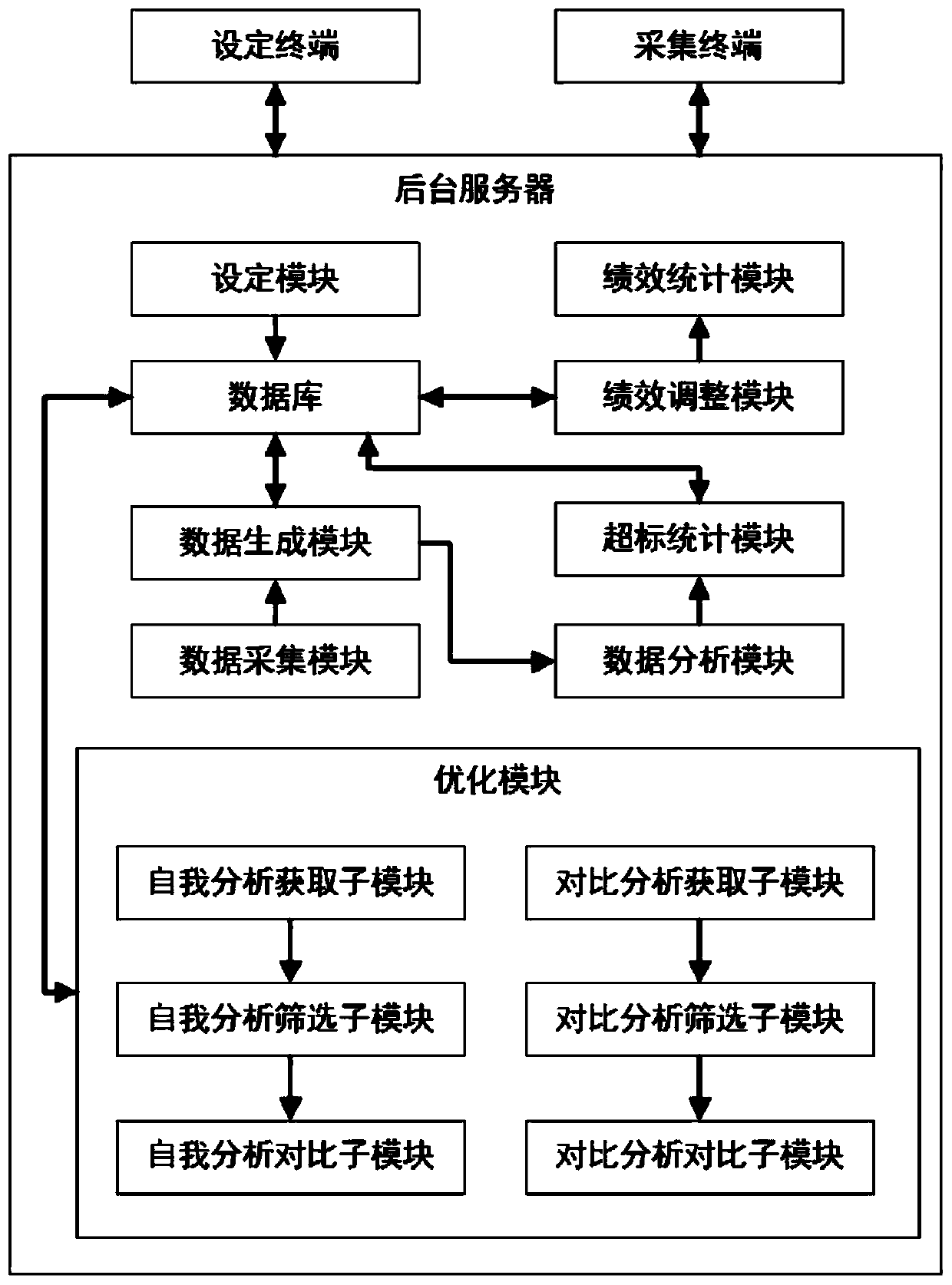

Cost optimization management system and method

The invention relates to the technical field of cost management, in particular to a cost optimization management system and method, and the system comprises a data generation module used for generating single data according to the actual information of parameters and a statistical rule; and a data analysis module used for acquiring the standard data and marking the single data as standard exceeding data when the single data exceeds the standard data. The method comprises the following steps: a data generation step: obtaining a statistical rule, generating process data according to actual parameter information and the statistical rule, and generating single data according to the process data; and a data analysis step: obtaining standard data, and when the single data exceeds the standard data, marking the single data as standard exceeding data. By adopting the scheme, the single data can be automatically generated according to the obtained parameters, and the standard exceeding data can be screened out according to the generated single data and the set standard data to remind a manager.

Owner:重庆回形针信息技术有限公司

A low-power on-line monitoring device for high-voltage cables based on nb-iot

ActiveCN113267707BWide coverageMany connectionsNetwork traffic/resource managementParticular environment based servicesData packCurrent sensor

The invention discloses an NB-IOT-based high-voltage cable low-power online monitoring device, including a current sensor, an AD conversion module, a main control chip, a PC terminal, an upper computer, an NB-IOT wireless communication module, a sensor group and power management module. The present invention uses the main control chip to classify the various required data according to the priority of the equipment working mode. The sheath current data and the fault recording data are set as the first priority. In all working modes, this level of data needs to be transmission. Data such as temperature, vibration, and device information are set as the second priority, and data at this level will only be transmitted in normal working mode. During data transmission, the size of the data packet is limited, and the data packet with too large amount of data is eliminated to reduce the upload of invalid data. Under different working modes, the frequency of data communication and the transmission volume of data communication will also be changed accordingly. The communication power consumption is reduced, and the normal operation of the device is also guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

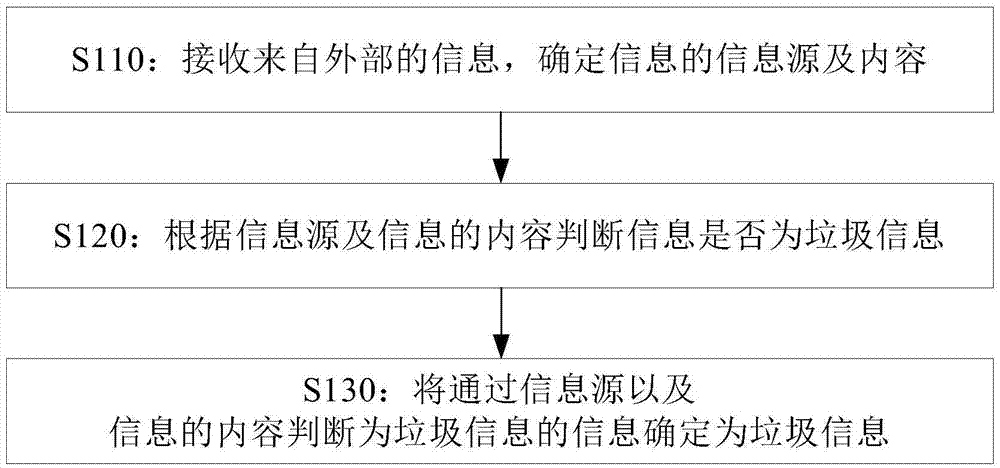

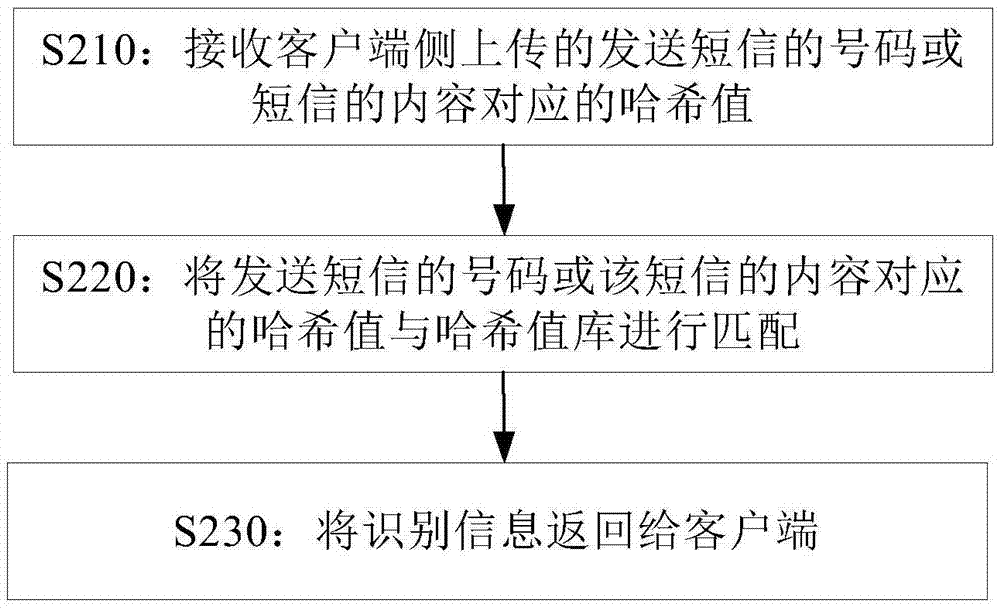

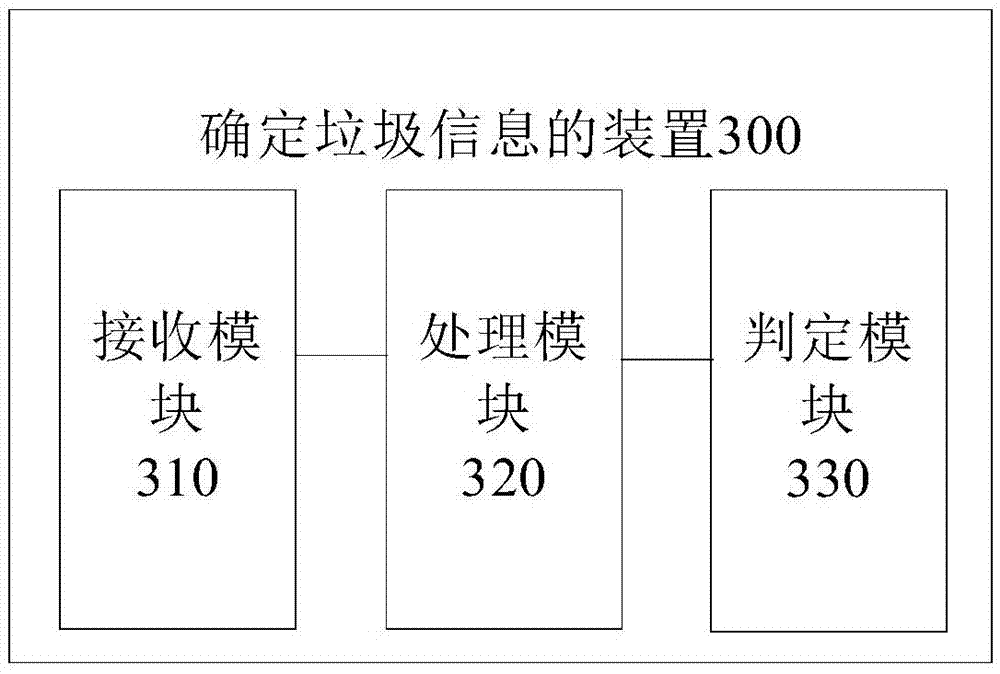

Method and device for determining garbage information

InactiveCN106878994AGuarantee the validity of identificationMeets requirementsMessaging/mailboxes/announcementsTransmissionClient-sideConsent Type

The present invention provides a method and device for determining garbage information. The method comprises: receiving information from the outside, and determining the information source and content of the information; determining whether the information is garbage information or not according to the information source; when determining that the information source is not garbage information, determining whether the information is garbage information or not according to the content of the information; and determining the information which is determined as garbage information through the information source or the content of the information as garbage information. According to the technical scheme, the method and device for determining garbage information can rapidly identify whether the information is garbage information or not through information source. Besides, on the basis of ensuring the identification validity of the garbage short message, the problem is avoided that the content of the short message is directly uploaded to a server without the asking users' consent to cause invasion of user personal privacy, the pressure of uploading through a client and processing through a cloud server is relieved after local computing process, the identification efficiency is improved, and the user demand is satisfied.

Owner:BEIJING QIHOO TECH CO LTD +1

Live broadcast scene video automatic production system

The invention relates to a live broadcast scene video automatic production system. The system comprises a monitoring video recording device which is disposed in an anchor room and is used for carrying out the video recording operation of a live broadcast scene of an anchor, so as to obtain a plurality of continuous frames of real-time captured images, and each real-time captured image is provided with a timestamp different from that of other real-time captured images; an electronic control switch is used for stopping the video recording operation of the monitoring video recording equipment to obtain a live broadcast recorded video when a recording ending instruction is received; the electronic control switch is further used for continuously keeping the video recording operation of the monitoring video recording equipment when receiving the recording keeping instruction. The live broadcast scene video automatic production system is reliable in design and convenient to operate. A live broadcast operator can be helped to reduce meaningless video recording and video uploading, so that effective management of the video production order and the video live broadcast order is realized.

Owner:徐静思

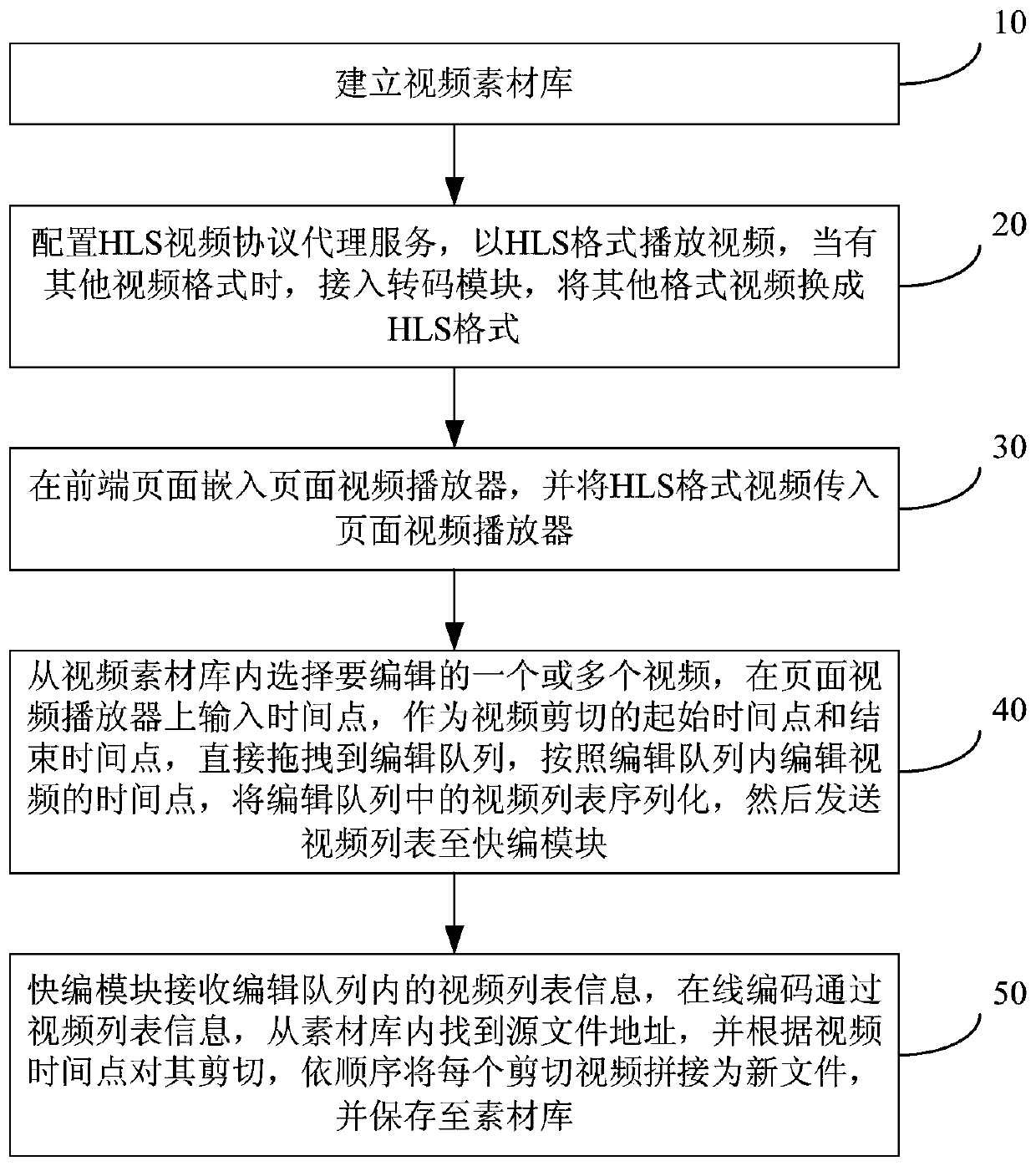

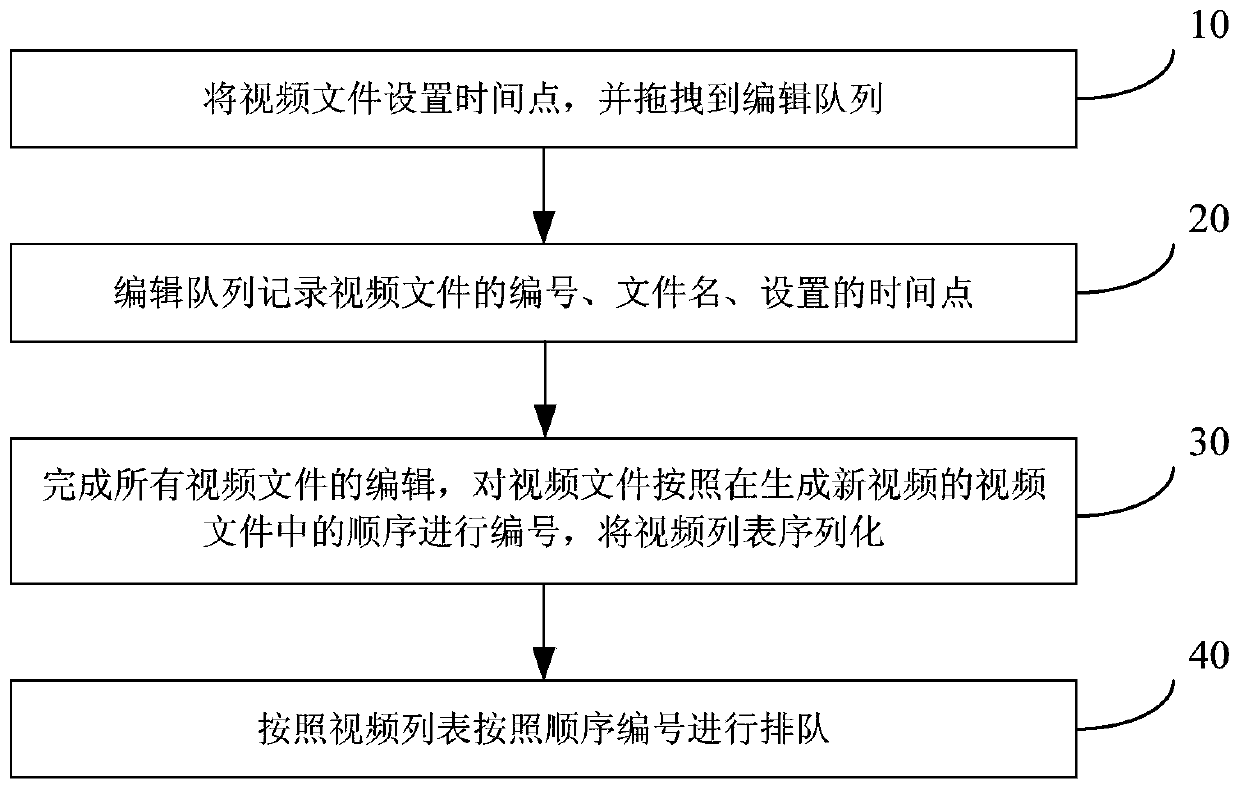

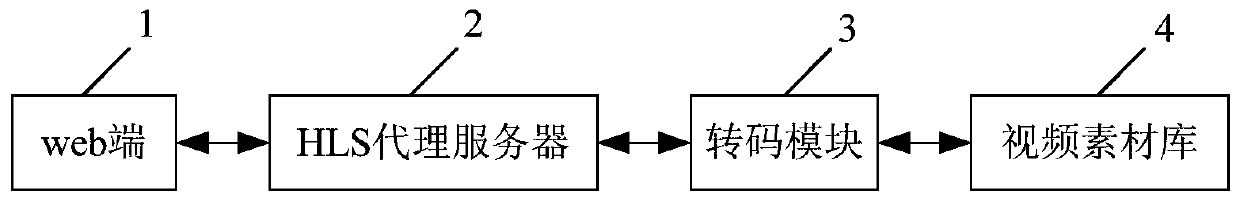

Method and system for online fast video editing based on web terminal

ActiveCN106791933BImprove experienceReduce uploadSelective content distributionHttp live streamingVideo processing

The invention relates to a web-client-based online quick video editing method and system; the system comprises a web client, an HLS (HTTP live streaming) proxy server, a transcoding module, a video material base; the web client is connected with the HLSC proxy server; the HLS proxy server is connected with the video material base through the transcoding module. The web client is used to directly acquire video files form the video material base, the video files of various formats are converted into HLS files through the transcoding module, a Flash player is used to edit the video files on a quick-editing display interface of the web client by configuring HLS proxy service, video lists in an editing queue are serialized and are spliced according to file numbers and setting time points, and editing of the video files is achieved. The web-client-based online quick video editing method and system provide online video reading with no client support, the frequency of a user uploading or downloading videos is reduced, mullite editing is available after single uploading, and through video processing based on HLS protocol, it is possible to acquire precise video positions and improve editing effect.

Owner:HANGZHOU ARCVIDEO TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com