Tin-dropping electric soldering iron

An electric soldering iron and tin dripping technology, which is applied in the direction of soldering iron, tin feeding device, auxiliary device, etc., can solve the problems of rosin volatilization, inconvenient wire feeding of electric soldering iron, and affecting welding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

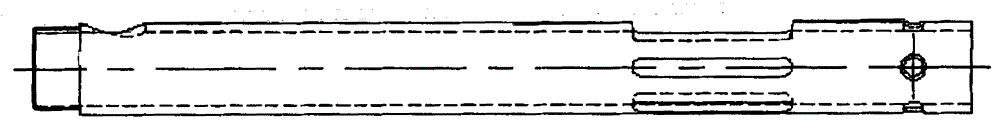

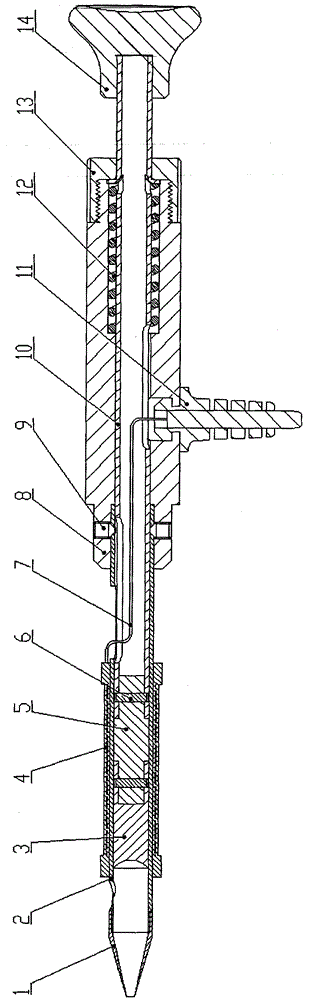

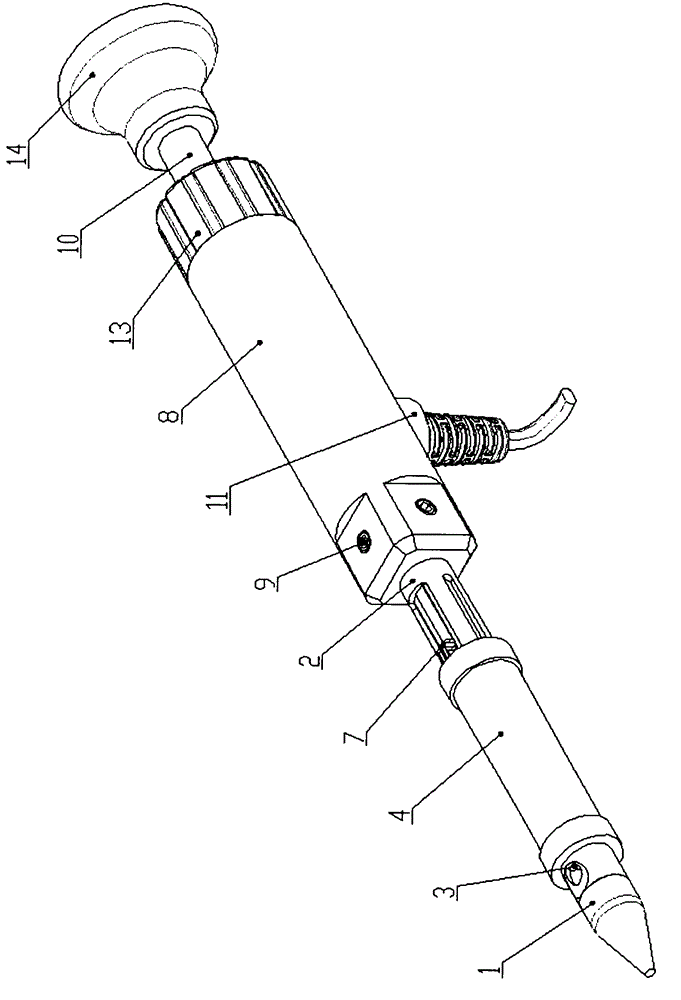

Image

Examples

Embodiment Construction

[0028] When welding, put the solder wire into the wire feeding hole 15, press the button 14, the piston annular cutting edge 18 and the outer sleeve cutting edge 16 work together to cut the solder wire and seal it in the melting tin chamber between the welding tip 1 and the piston 3 After the solder wire is melted, continue to press the button 14 to push the solder liquid through the tin hole at the front of the nozzle. The solder flow can be controlled by controlling the speed at which the button 14 is pressed. After the soldering is completed, the button 14 is released, and the push rod 10 drives the button. 14 returns to its original position under the effect of back-moving spring 12.

[0029] When reclaiming the soldering tin, first press the button 14 empty, and when the piston resets under the action of the back-moving spring 12, a pressure difference can be formed in the melting tin cavity, and the soldering liquid can be recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com