Polyamide moulding compound and use thereof and moulded bodies produced from said moulding compound

A technology of polyamide and molding compound, applied in the field of molding compound in the preparation of molded products, can solve the problems of prolonging the cooling time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

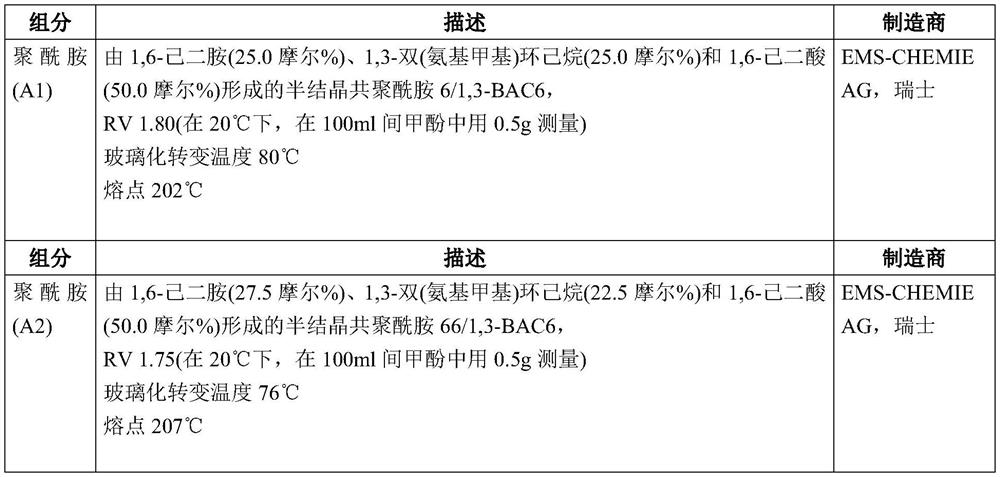

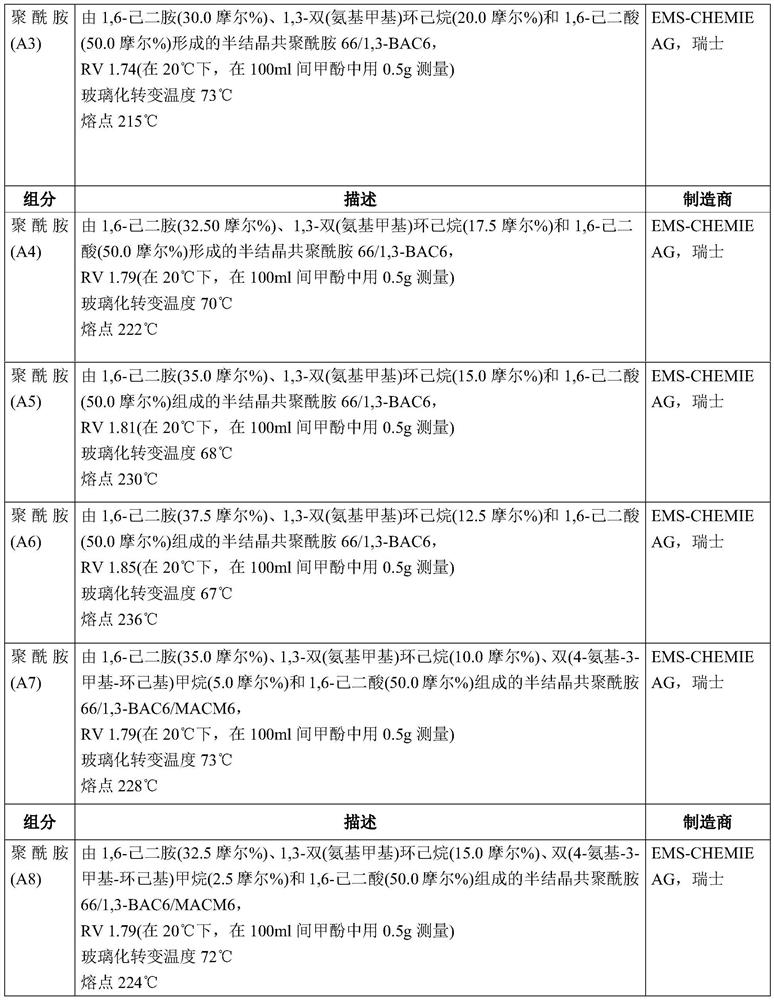

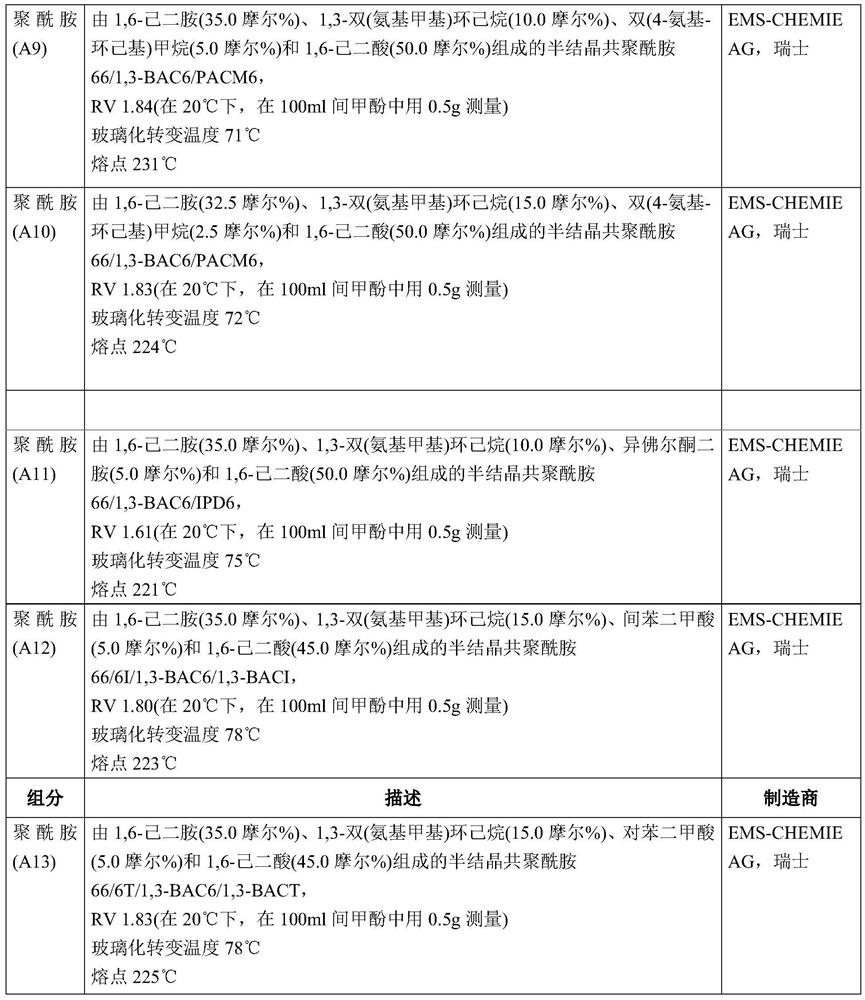

Method used

Image

Examples

preparation example Construction

[0142] The preparation of the copolyamides according to the invention is carried out in a manner known per se in a known stirrable autoclave having a display vessel and a reaction vessel:

[0143] Deionized water is present in the display container with added monomers and possible additives. This is followed by several inerting treatments with nitrogen. Heat to 180°C to 230°C while stirring at the pressure employed to obtain a homogeneous solution. The solution is pumped through a screen into the reaction vessel and heated to the desired reaction temperature of 250°C to 300°C at a pressure of maximum 30 bar. During the pressure stage, the reaction system is maintained at the reaction temperature for 2 hours to 4 hours. During the subsequent expansion phase, the pressure drops to atmospheric pressure within 1 to 2 hours, while the temperature may drop slightly. In the subsequent degassing stage, the reaction system is maintained at atmospheric pressure and a temperature of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com