Lighting assembly of AOI equipment

A technology of lighting components and equipment, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low scanning quality of the camera, adjustment of the lighting angle of the light source, difficult adjustment of the light source, etc., and achieve good stability and simple structure , to prevent the effect of random rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and embodiment;

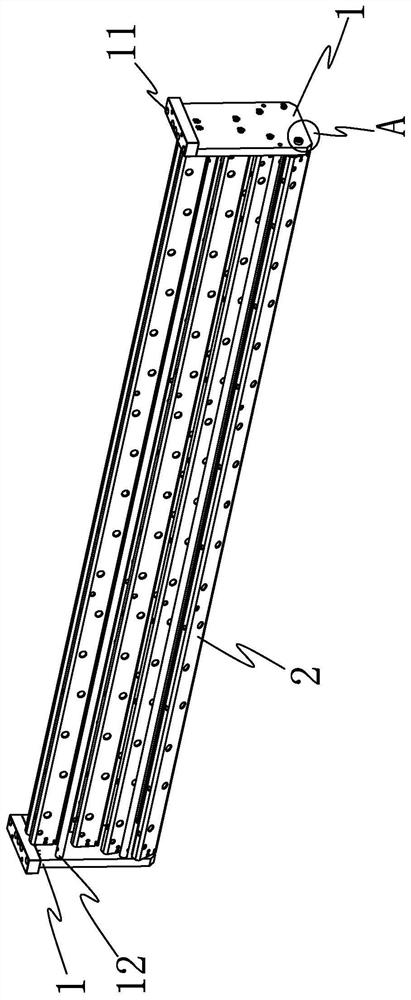

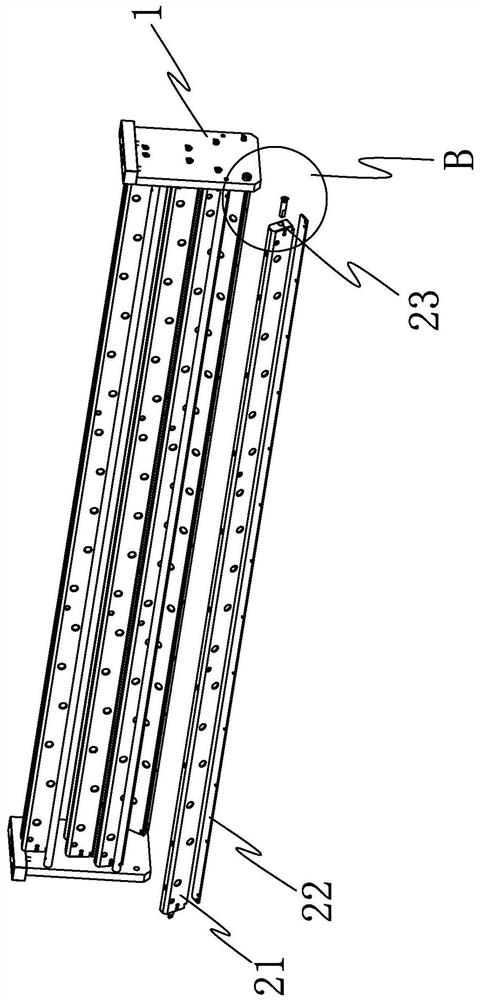

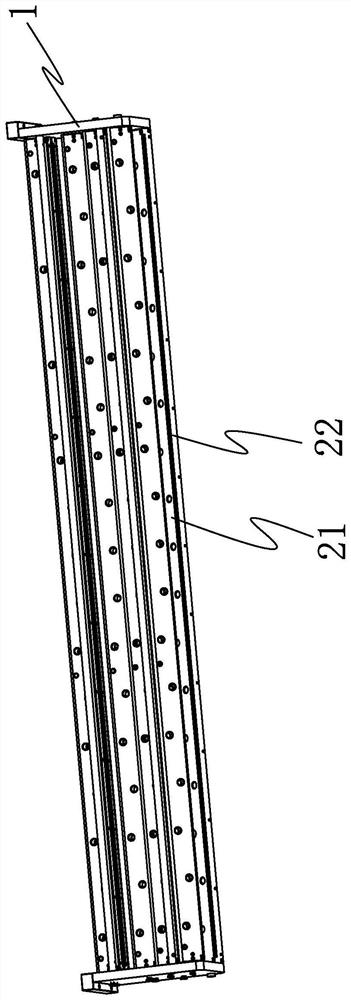

[0020] see Figure 1-Figure 5 , a lighting assembly for AOI equipment, including brackets 1 arranged at intervals on the left and right, a plurality of groups of light source assemblies 2 are arranged between the brackets 1, and a plurality of shaft holes are opened on the bracket 1, and the shaft holes The quantity corresponds to the quantity of the light source assembly 2, an adjustment shaft 24 is arranged in the shaft hole, the light source assembly 2 is fixed on the adjustment shaft 24, and the angle of the light source assembly can be adjusted by rotating the adjustment shaft , That is to realize the advantages of adjusting the irradiation, the adjustment shaft 24 and the bracket 1 are provided with a positioning locking device 3, the positioning locking device has the function of locking the adjustment shaft to prevent the adjustment shaft from rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com