Motor mounting frame, swing cutting mechanism and double-head cutting machine

A technology of motor mounting frame and cutting mechanism, which is applied in metal processing and other directions, can solve problems such as equipment failure, sawdust flying down on electrical components, and affecting the entry and exit of saw blades, so as to improve precision and durability, The effect of reducing the exposure of the saw blade and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

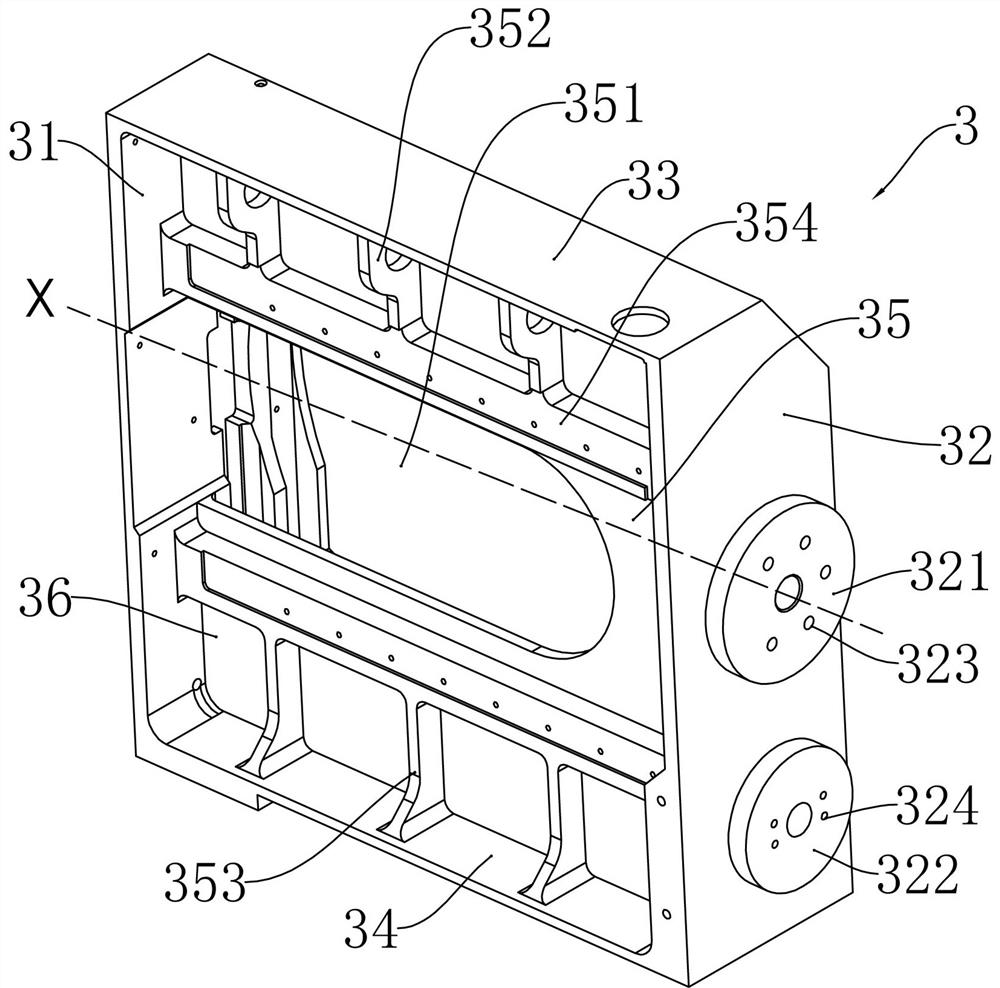

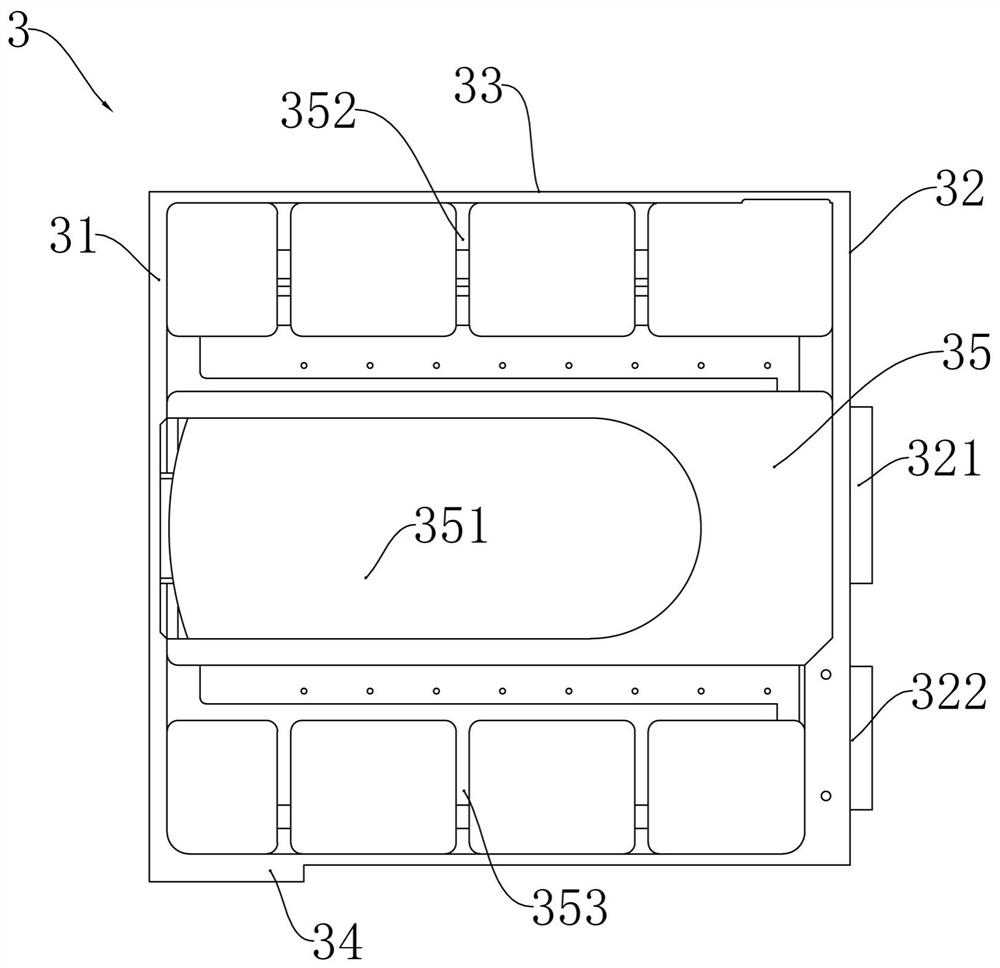

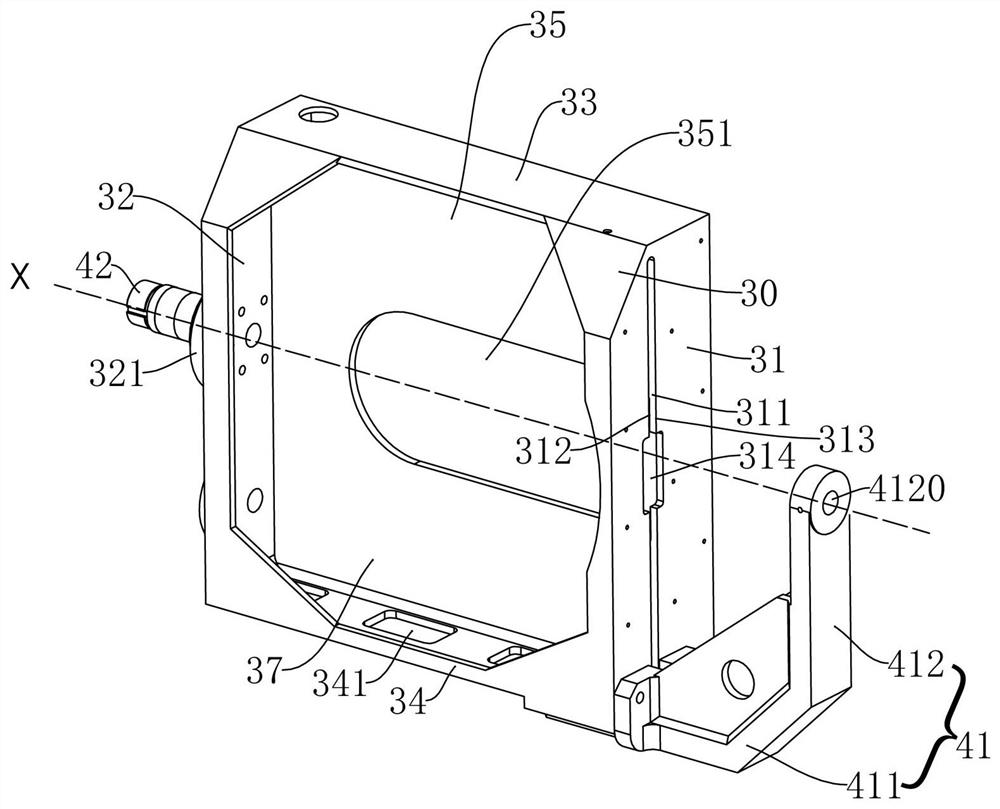

[0033] The structure of the double-head cutting machine applying the technical solution of the present invention, the swing cutting mechanism 2b and the motor mounting frame applied to the double-head cutting machine will be further described below in conjunction with the accompanying drawings.

[0034] Such as Figure 6 As shown, the present invention proposes a double-head cutting machine, the cutting machine includes a horizontal frame 1, the horizontal frame 1 is arranged longitudinally, and the horizontal frame 1 is provided with Collecting trough 10, two swing cutting mechanisms, i.e. front swing cutting mechanism 2a, rear swing cutting mechanism 2b, they are arranged front and back on the described horizontal frame 1, wherein the swing cutting mechanism 2a positioned at the front is fixed on the On the horizontal frame 1 , the latter swing cutting mechanism 2 b is movably arranged on the horizontal frame 1 . The two oscillating cutting mechanisms have the same supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com