Cover for operating element and operating assembly

A technology for operating elements and covering parts, which is applied to devices, control components, and instruments that prevent/restrict/restore the movement of parts of a control mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

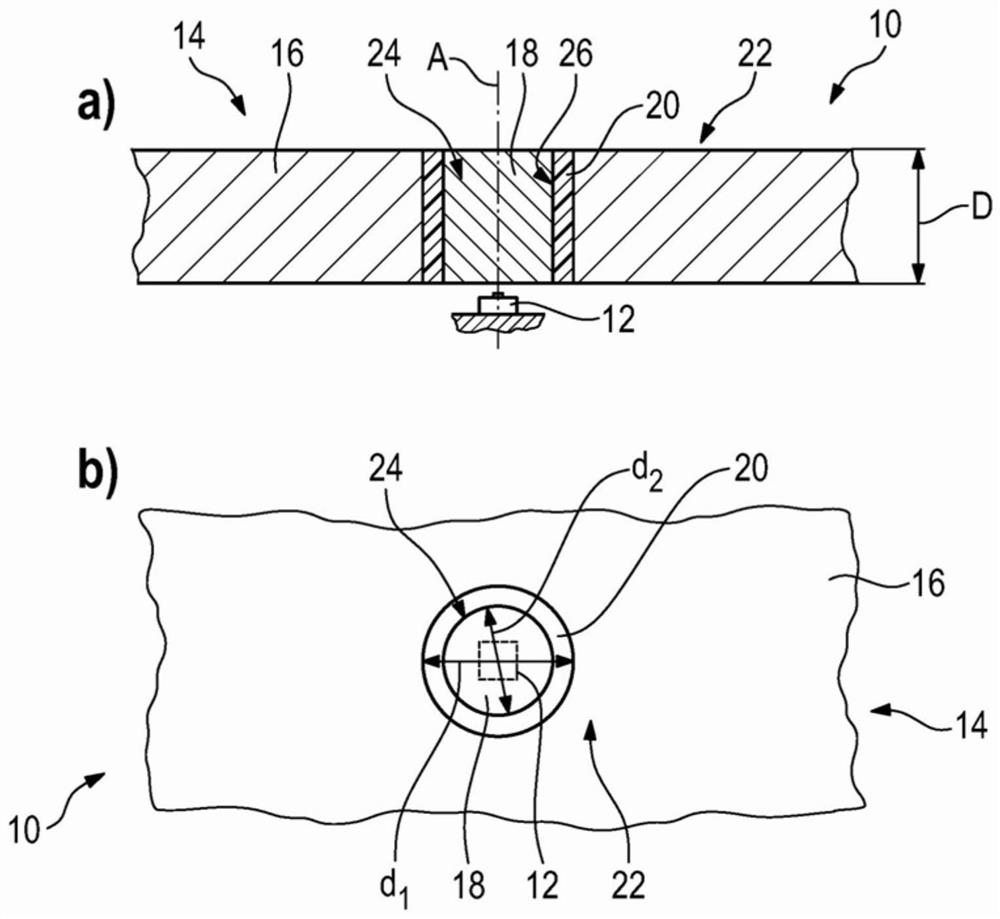

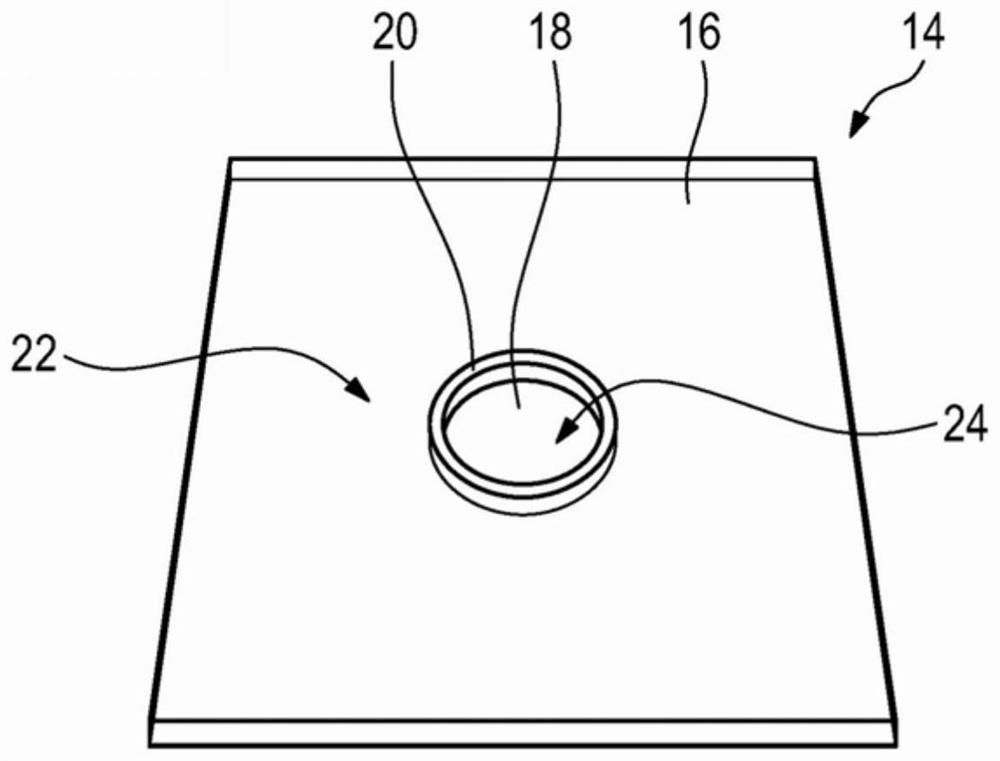

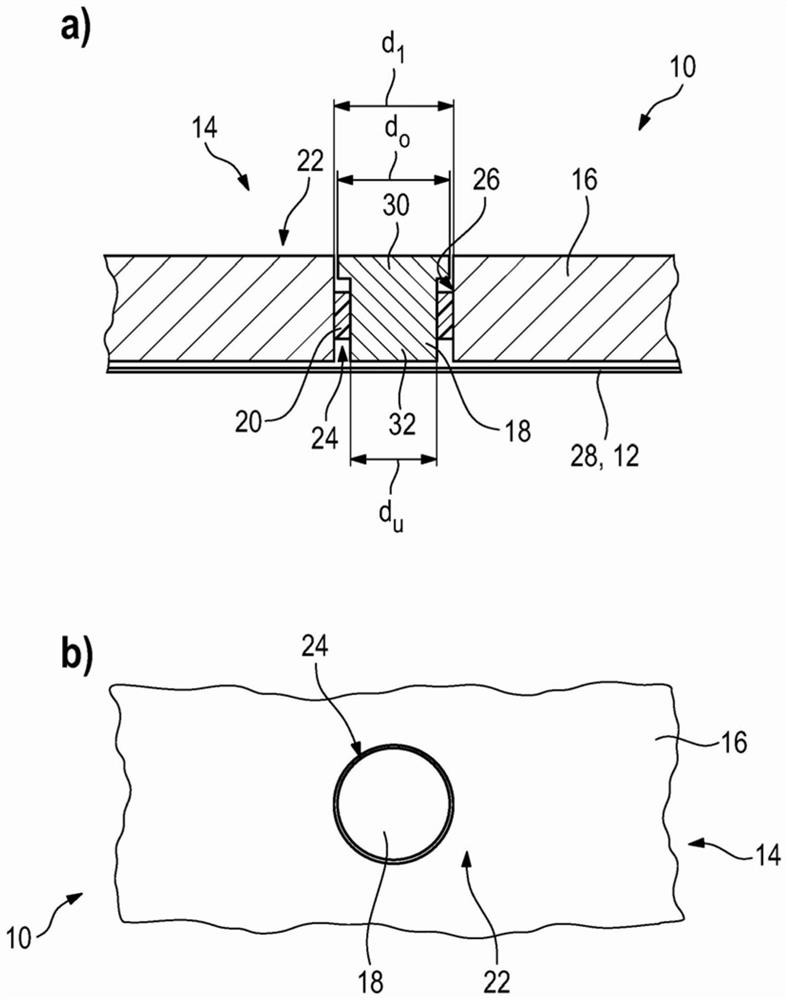

[0027] figure 1 a and 1 b show a sectional or side view of the operating assembly 10 with the operating element 12 and the cover 14 for the operating element 12 . exist figure 2 A perspective view of the operating unit 10 can be seen in .

[0028] FIG. 14 includes a basic body 16 , a button part 18 and a support ring 20 .

[0029] In the exemplary embodiment shown, the base body 16 is a plate made of a solid solid material, such as glass, which has two flat, parallel surfaces. Alternatively, the base body 16 can consist of transparent plastic.

[0030] Of course, the base body 16 and / or the button part 18 can also be produced from metal, ceramics, wood or other rigid solid materials.

[0031] The surface of the base body 16 facing the operator of the operating assembly 10 forms the operating surface 22 of the cover 14 .

[0032] In the base body 16 , in particular perpendicularly to the operating surface 22 , a through-opening 24 is formed, which extends through the enti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com