Transfer printing machine

A printing machine and printing technology, which is applied in the direction of rotary printing machine, printing machine, transfer printing, etc., can solve the problems of increased process, heavy coil material, high labor cost, etc., and achieve the effect of uniform distribution of cold water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

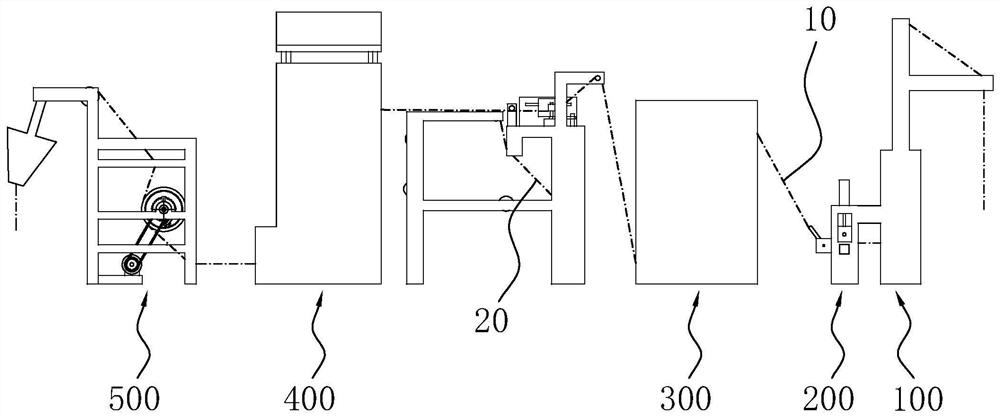

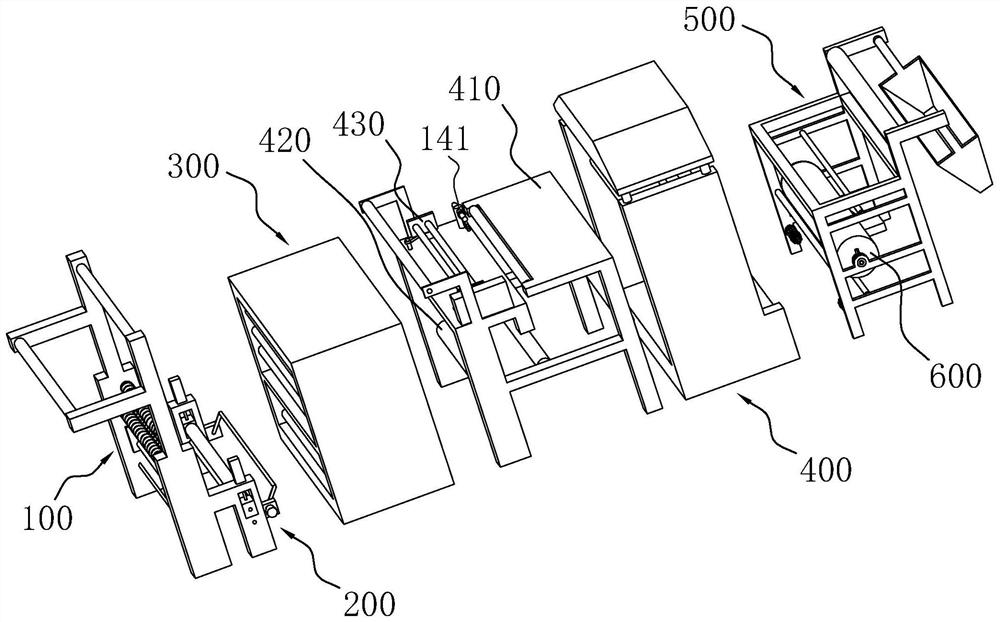

[0050] Embodiment 1: a kind of transfer printing machine, such as figure 1 and figure 2As shown, along the conveying direction of the cloth 10, the opening device 100, the feeding device 200, the photoelectric weft adjustment device 300, the printing device 400 and the receiving device 500 are sequentially included, and the cloth 10 and the transfer paper 20 are in the figure 1 Indicated by a dotted line.

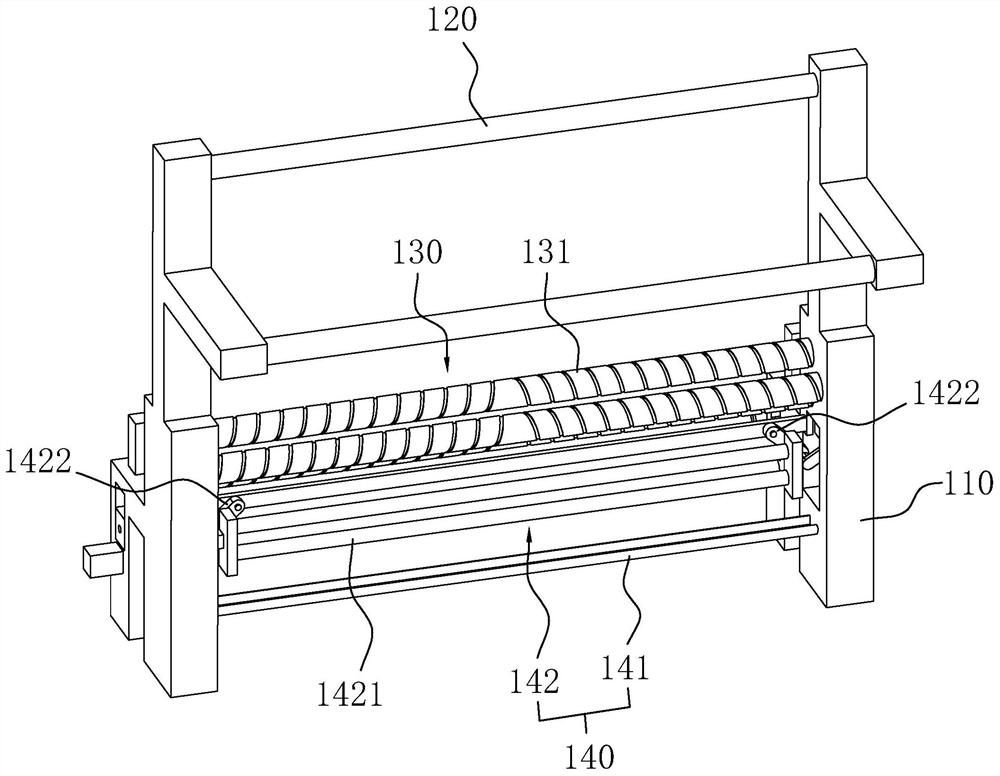

[0051] like image 3 As shown, the opening device 100 includes an opening frame 110, a lifting roller 120, an opening roller group 130 and an initial deviation correction mechanism 140, the lifting roller 120 is arranged on the top of the opening frame 110, and the opening roller group 130 includes two And the above double helical rollers 131, take three double helical rollers 131 as example in this example, three double helical rollers 131 are arranged in parallel, and two double helical rollers 131 are positioned on the same vertical plane, another double helical rolle...

Embodiment 2

[0068] Embodiment 2: as Figure 8 and Figure 9 As shown, the difference from Embodiment 1 is that the structure of the cooling roller 600 is different. In this embodiment, the two rotating shafts 620 of the cooling roller 600 are jointly connected with a water inlet pipe 624, and the middle of the water inlet pipe 624 is located at the middle position of the roller 610. A partition plate 6243 is provided at the location, and water outlet holes 6244 are arranged on the side walls of the water inlet pipe 624 on both sides of the partition board 6243. The axes are evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com