A kind of setting out method for bearing cushion stone construction

The technology of seat cushion and pedestal is applied in the field of lofting of bridge construction, which can solve the problems of tight fit of pre-embedded steel plates of supports and difficulty in lofting and measurement of support and stone construction, and achieves the effect of reducing workload and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

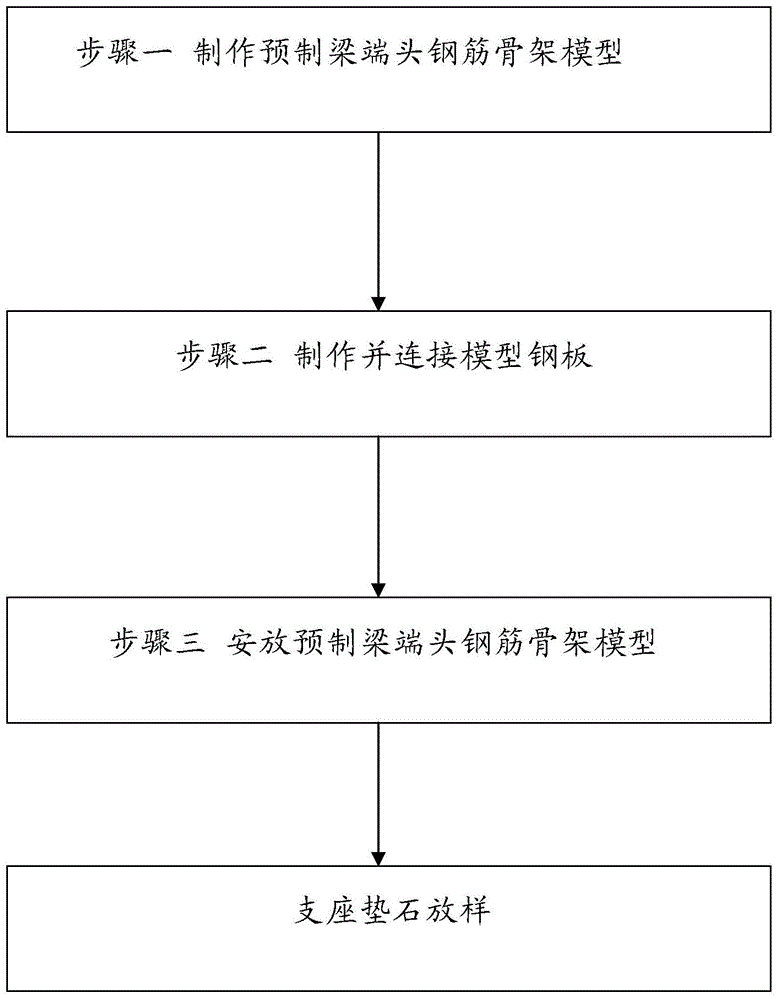

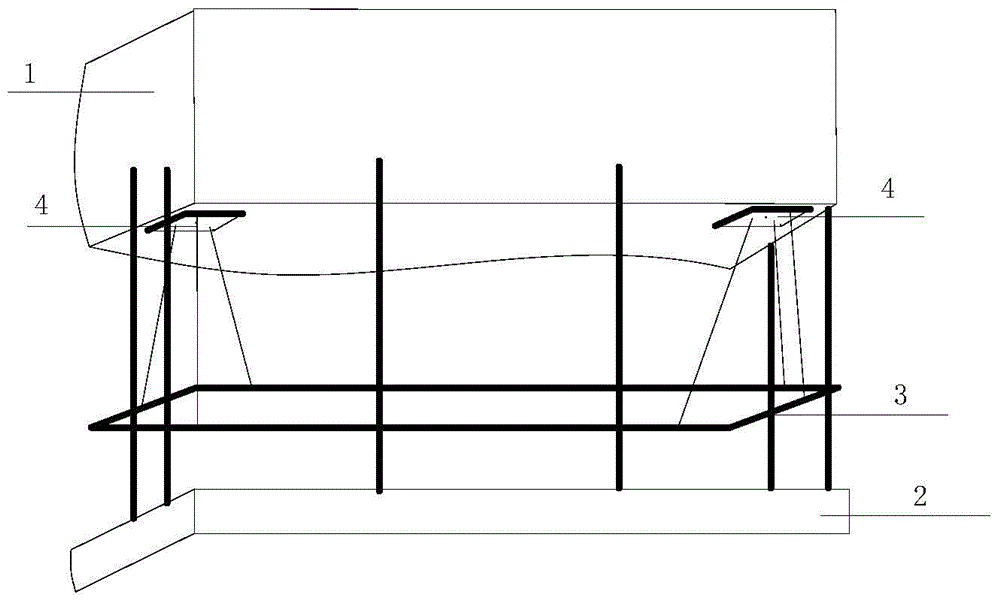

[0033] The concrete embodiment of the present invention is described as an example of a bridge type in which the upper structure is a simply supported prefabricated hollow slab girder, as figure 1 The method flow shown, using as figure 2 , image 3 , Figure 4 With the shown device, the construction lofting method of the bearing cushion stone comprises the following steps:

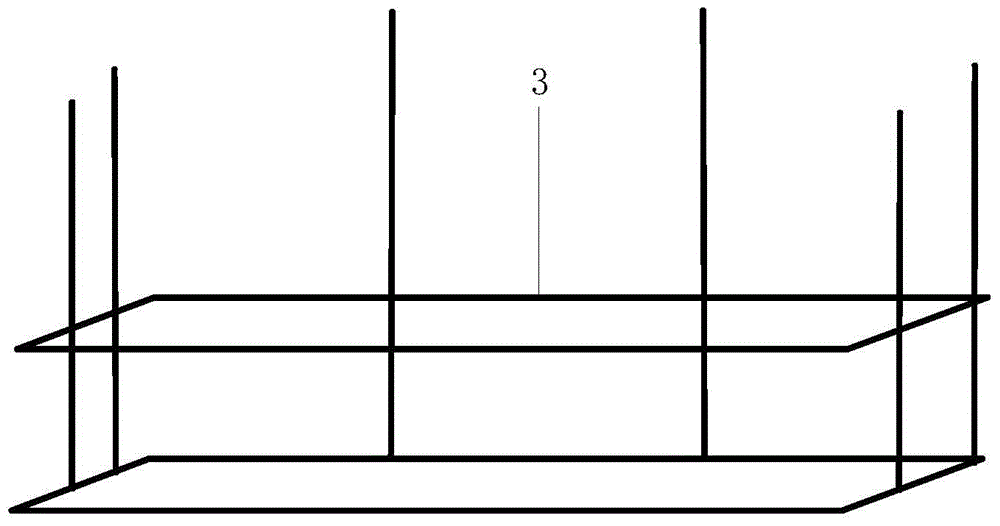

[0034] Step 1 Make the steel skeleton model at the end of the prefabricated beam 3

[0035] Place the prefabricated beam 1 on the prefabricated beam pedestal 2 with wooden square supports of equal thickness to make the prefabricated beam end reinforcement skeleton model 3, the bottom of the prefabricated beam end reinforcement skeleton model 3 is placed flat on the prefabricated beam pedestal 2, and the internal dimensions are the same as The end of prefabricated beam 1 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com