Environmental protection sewage treatment and purification device

A technology of sewage treatment and purification device, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Incoming sewage speed and other issues to avoid clogging the filter belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

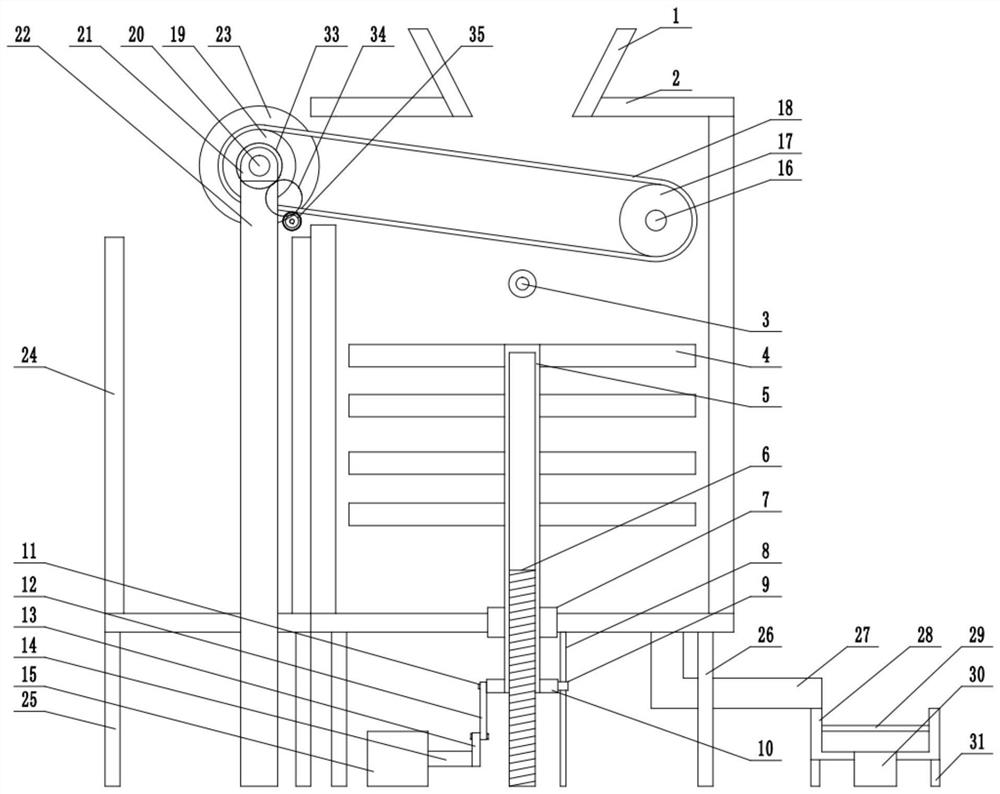

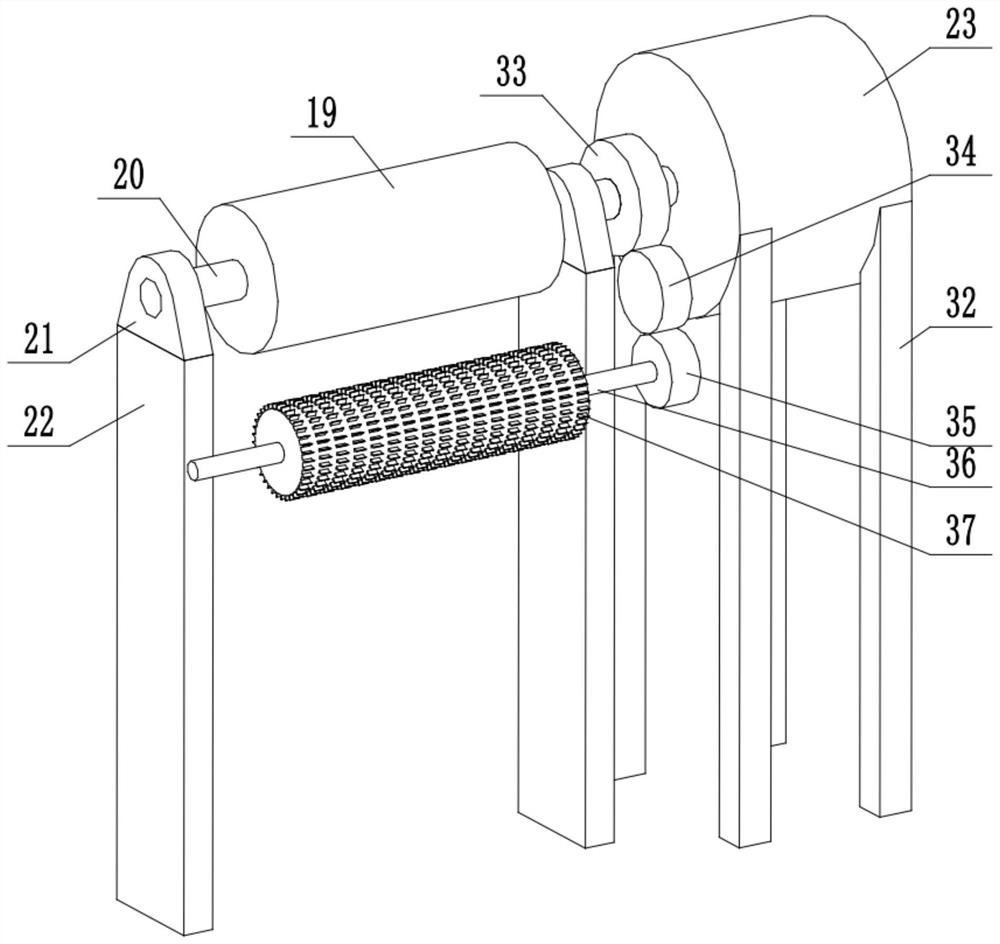

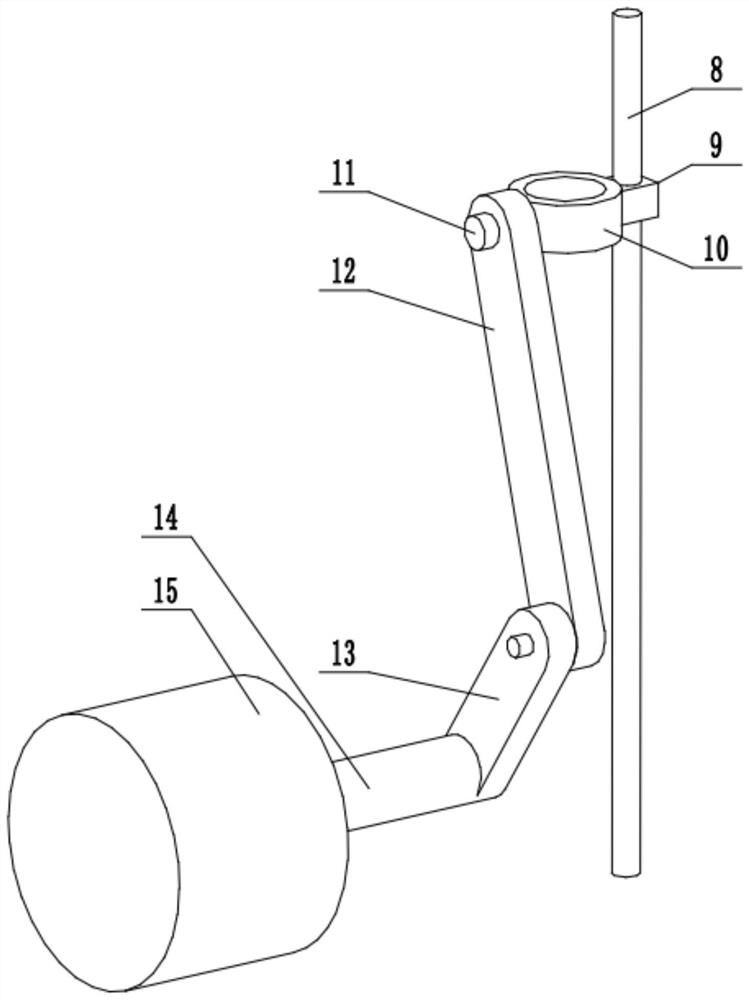

[0026] refer to Figure 1~3 , in an embodiment of the present invention, a sewage treatment and purification device for environmental protection includes a first motor 15, a first output shaft 14 is installed on one side of the first motor 15, and a first rotating rod 13 is fixed on the other end of the first output shaft 14 The other end of the first rotating rod 13 is hinged with the second rotating rod 12, the other end of the second rotating rod 12 is rotatably connected with the first rod body 11, one side of the first rod body 11 is fixed with a fixed bearing 10, and the other side of the fixed bearing 10 is fixed There is a punching fixing block 9, the middle part of the punching fixing block 9 is slidingly connected with a fixing rod 8, and the middle part of the fixing bearing 10 is fixed with a vertically upward hollow internal thread stirring shaft 5, and the internal thread of the hollow internal thread stirring shaft 5 is connected with a fixed An externally threa...

Embodiment 2

[0029] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that, wherein, the upper part of the sewage treatment frame 2 is provided with a flocculant feed port 3 for conveniently feeding the sewage treatment frame 2 Add flocculant.

[0030]The working principle of the present invention is: the first motor 15 drives the first output shaft 14 to rotate, the first output shaft 14 drives the first rotating rod 13 to rotate, the first rotating rod 13 drives the second rotating rod 12 to rotate, the second rotating rod 12 Drive the first rod body 11 to move up and down under the action of the hollow internal thread stirring shaft 5 and the fixed rod 8, the first rod body 11 drives the fixed bearing 10 to move up and down, the fixed bearing 10 drives the hollow internal thread stirring rod 5 to move up and down, and the hollow internal thread stirs 5 Rotate under the action of the threaded external thread cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com