Workpiece surface detection device and method for casting machining

A detection device and workpiece surface technology, which is applied to workpiece clamping devices, measuring devices, manufacturing tools, etc., can solve the problems of large manpower consumption, failure to achieve inspection results, time-consuming and labor-intensive problems, and achieve comprehensive detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

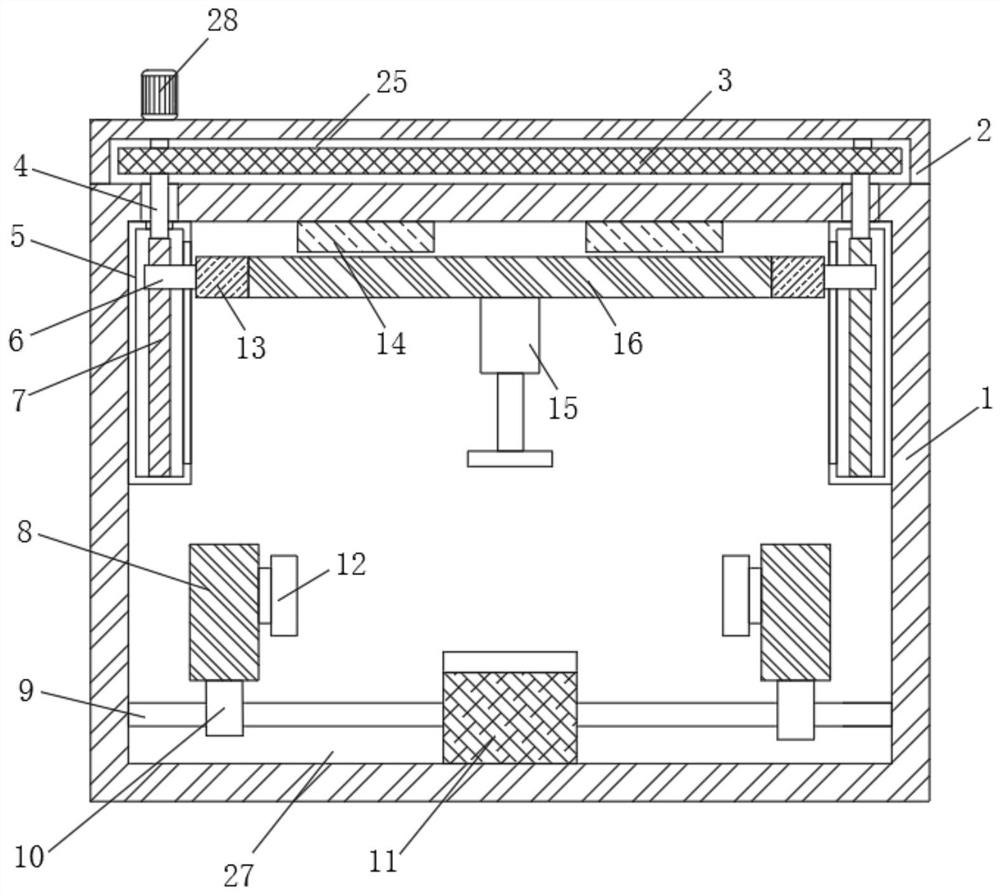

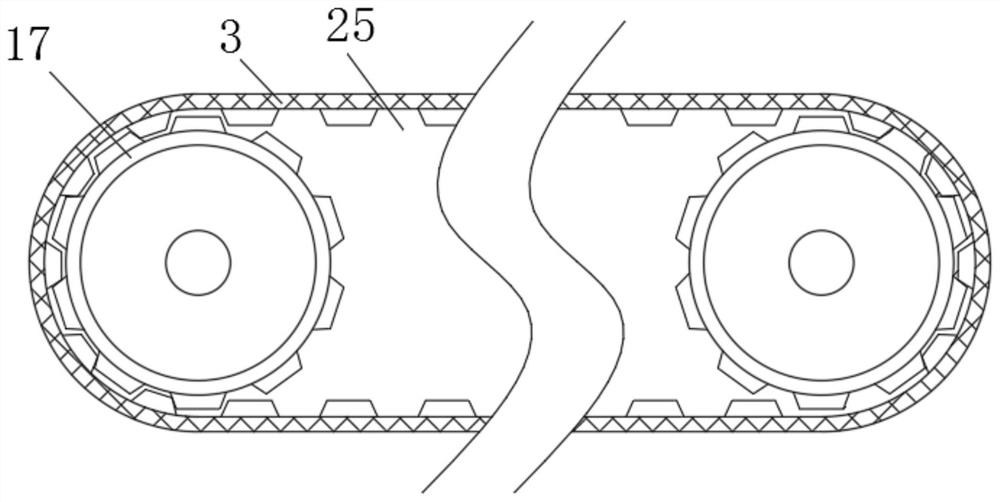

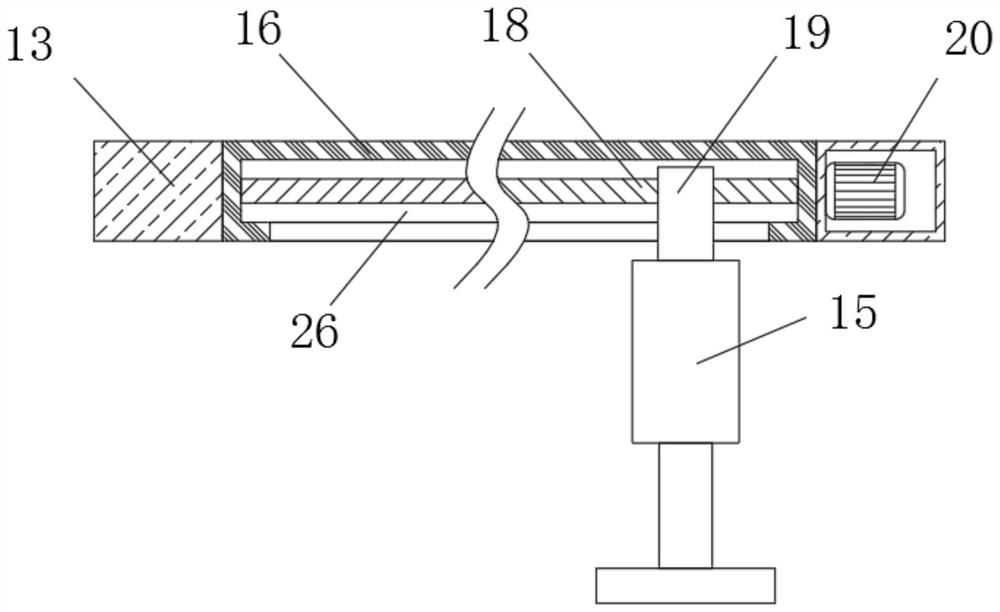

[0025] Example: such as Figure 1-6 As shown, a workpiece surface detection device and detection method for casting processing of the present invention includes a housing 1, a fixed box 2 is fixedly connected to the top surface of the housing 1, and the top of the fixed box 2 is provided with a fourth motor 28. The output ends of the four motors 28 run through the fixed box 2, the inside of the fixed box 2 is provided with a rotating mechanism 25, and the inside of the housing 1 is symmetrically provided with two first support boxes 5, and the two first support boxes 5 are fixedly connected to the shell respectively. On the two side walls of the body 1, two connecting blocks 13 are arranged between the two first supporting boxes 5, and a first motor 20 is arranged inside one of the connecting blocks 13, and the two first supporting boxes 5 are fixedly connected. There is a connecting plate 16, the bottom end surface of the connecting plate 16 is excavated with a movable groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com