A special conductive rotary head for electroplating equipment

A technology of electroplating equipment and rotary head, which is applied in the direction of current conduction devices, electrolytic components, electrolytic processes, etc., and can solve problems such as the reduction of the contact surface between the electroplating brush and the metal to be plated, the slowing down of the anion transmission speed of the electroplating brush, etc., and achieve faster The effect of blowing and dripping to increase the diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

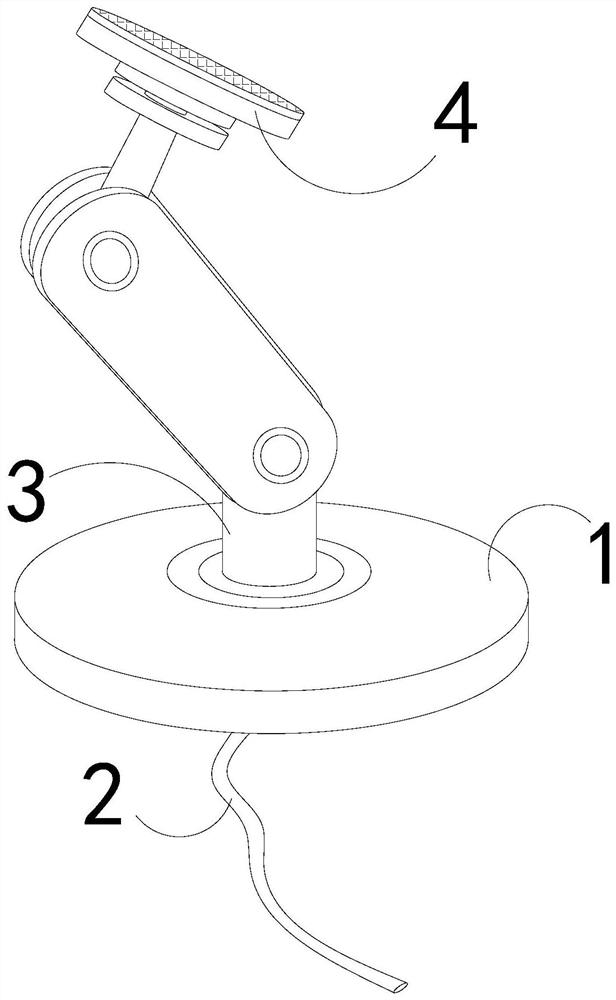

[0028] The invention provides a special conductive turret for electroplating equipment, the structure of which includes a base 1, a wire 2, a bearing 3, and a conductive mechanism 4. The wire 2 is installed at the center of the bottom of the base 1, and the bearing 3 is vertically installed on the base 1. At the top, the conductive mechanism 4 is movably matched with the top of the bearing 3 .

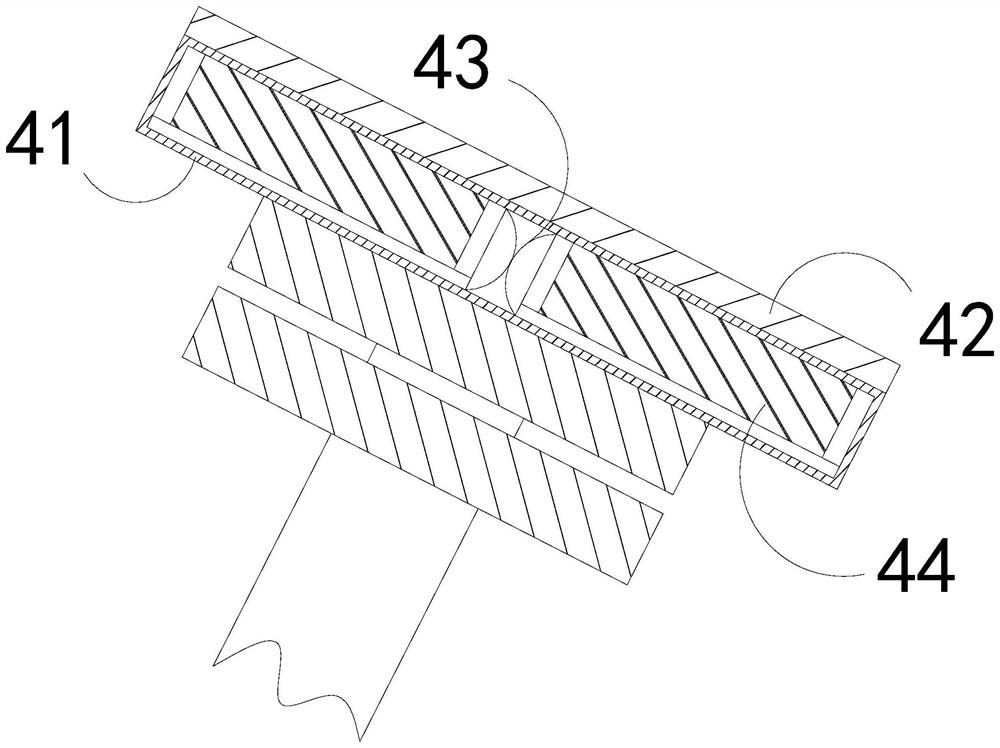

[0029] The conductive mechanism 4 is provided with a support 41, an electroplating brush 42, a push block 43, and a vibration device 44. The electroplating brush 42 is installed on the upper surface of the support 41, and the vibration device 44 is located inside the support 41. The push block 43 Sandwiched between vibration devices 44 .

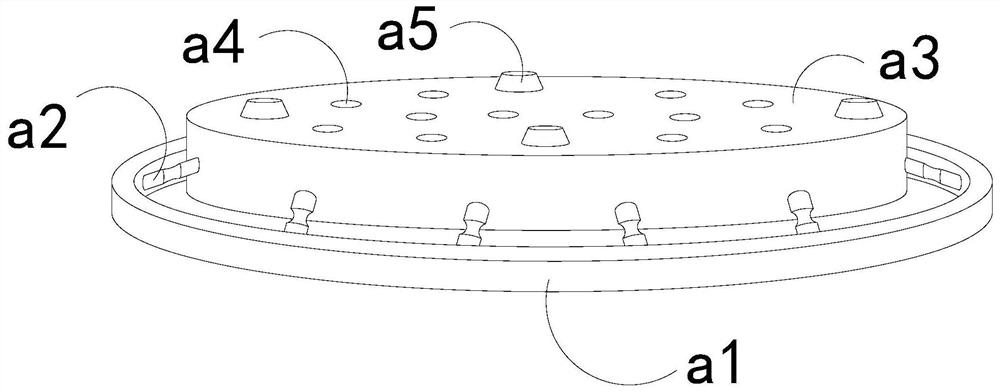

[0030] Wherein, the vibration device 44 is provided with a support ring a1, a telescopic rod a2, a built-in plate a3, an opening a4, and a bump a5, the support ring a1 is located outside the...

Embodiment 2

[0036] as attached Figure 6 to attach Figure 8 Shown:

[0037]Wherein, the opening a4 is provided with a limit bar r1, a dispersion block r2, a scraper r3, and an exhaust port r4, the limit bar r1 is arranged on both sides of the opening a4, and the dispersion block r2 is sandwiched between the limit bar r1 In between, the scraper r3 is embedded at both ends of the dispersion block r2, and the exhaust port r4 runs through the upper and lower surfaces of the dispersion block r2. There are three exhaust ports r4, and the diameter gradually decreases from top to bottom. It is beneficial to increase the gas diffusion area at the top of the exhaust port r4, and the side end of the scraper blade r3 is pointed, which is beneficial to accelerate the dropping of the electroplating solution on the inner wall of the opening a4.

[0038] Wherein, the exhaust port r4 is provided with a support frame t1, a blocking plate t2, and a spring t3, the support frame t1 is located outside the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com