Foldable drying machine

A dryer and folding drying technology, applied in the field of dryers, can solve the problems of collapse of folding brackets, failure to function, inconvenience of normal use, etc., and achieve the effect of not being easy to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

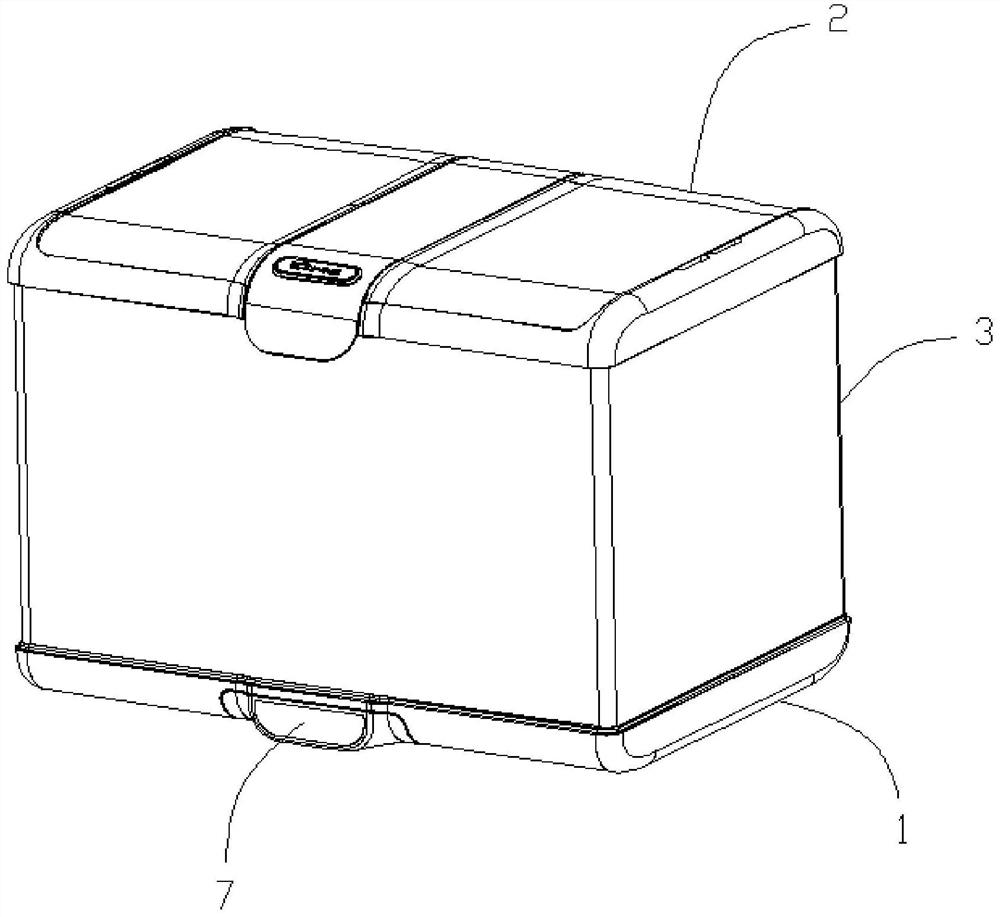

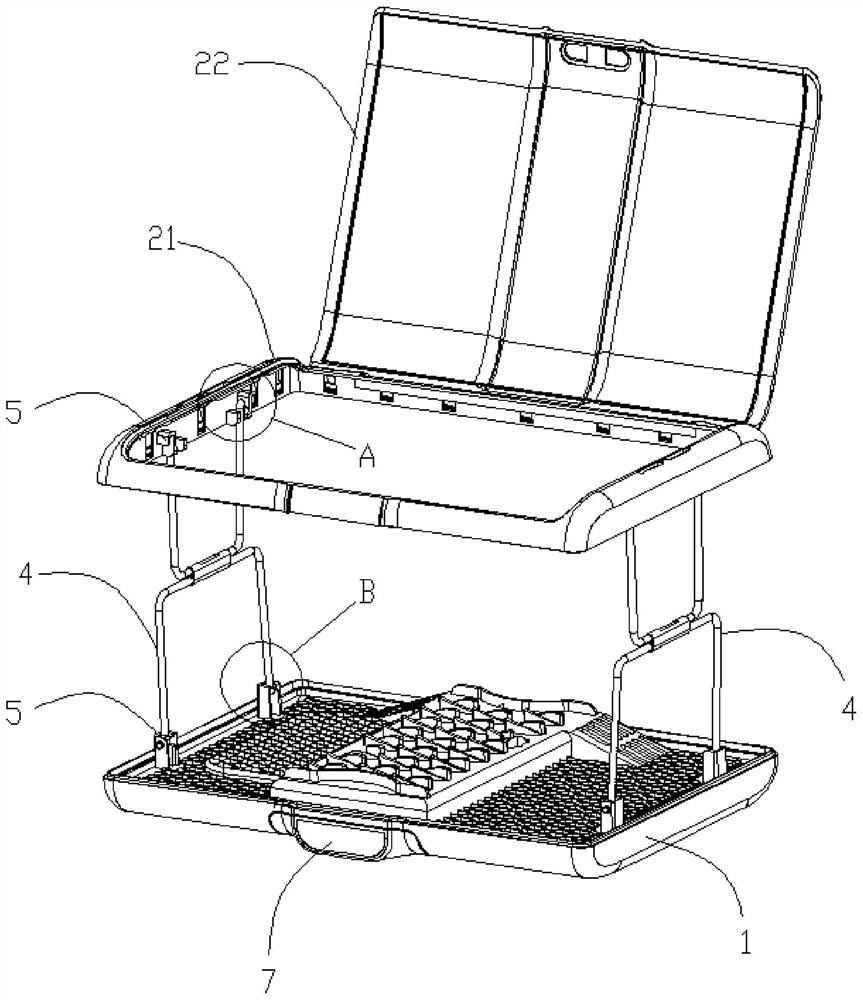

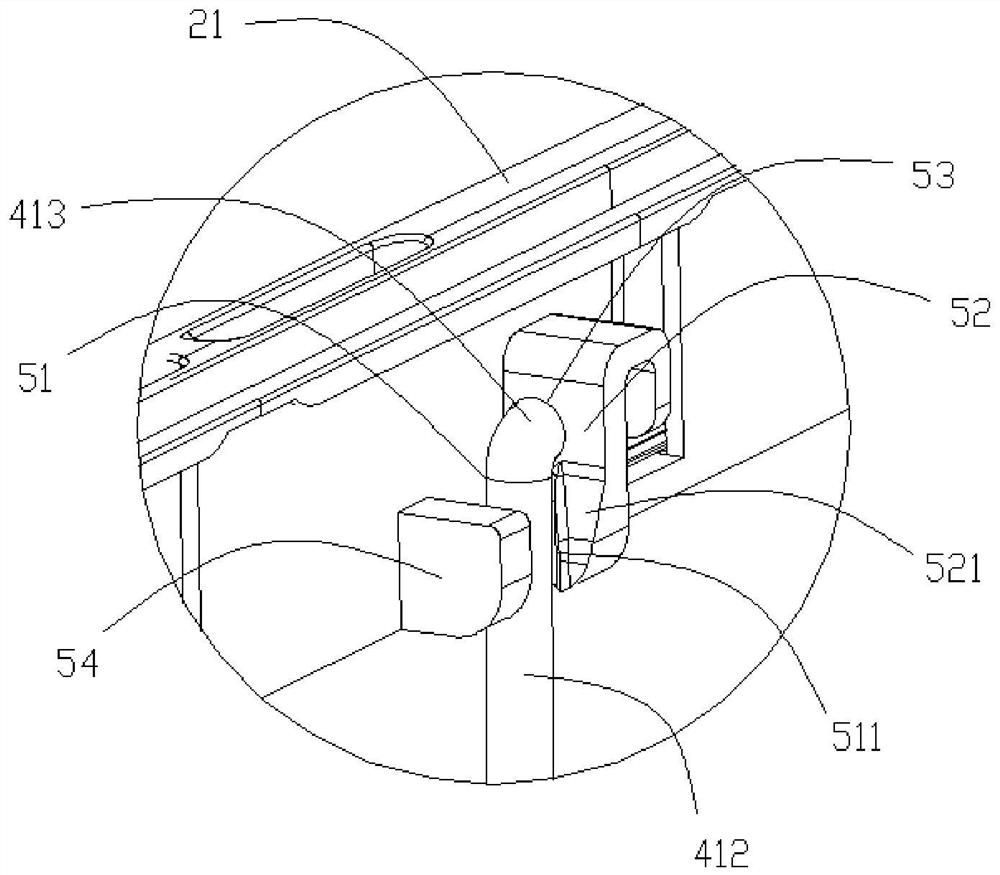

[0049] refer to Figure 1 to Figure 8, the invention discloses a dryer, comprising a base assembly 1, an upper cover assembly 2, a drying cover 3 and a support assembly. The base assembly 1 is provided with a host assembly 7 for providing hot air. Preferably, the host assembly 7 is detachably arranged on the base assembly 1; the support assembly is connected to the base assembly 1 and the upper cover The upper cover assembly 2 is stretched between the components 2; the drying cover 3 is connected between the base assembly 1 and the upper cover assembly 2 to form a drying chamber for accommodating clothes.

[0050] Wherein, the support assembly is at least two sets of hinge assemblies 4, the two ends of the hinge assembly 4 are respectively hinged on the base assembly 1 and the upper cover assembly 2, and the upper cover assembly can be moved by the hinge assembly 4 2 is supported so that the drying cover 3 forms a drying chamber for accommodating clothes between the base asse...

Embodiment 2

[0068] refer to Figure 9 to Figure 15 The difference between this embodiment and Embodiment 1 is that the dryer disclosed in this embodiment specifically discloses a specific structure in which the cloth cover 31 is detachably connected between the base assembly 1 and the upper cover assembly 2 .

[0069] The dryer provided in this embodiment includes the base assembly 1 , the upper cover assembly 2 , the cloth cover 31 and the supporting assembly as described in the first embodiment.

[0070] In this embodiment, the upper and lower ends of the cloth cover 31 are provided with buckle edges 32, the base assembly 1 and the upper cover assembly 2 are both provided with a card slot 6, and the card slot 6 is provided with a The buckle portion 61 is snap fit with the buckle edge 32 ; through the relative fit between the buckle edge 32 and the buckle portion 61 , the cloth cover 31 is detachably connected between the base component 1 and the upper cover component 2 .

[0071] Wher...

Embodiment 3

[0084] refer to Figure 16 to Figure 22 The difference between this embodiment and Embodiment 1 or 2 is that the dryer disclosed in this embodiment specifically discloses a detachable main body structure in which the main body assembly 7 is detachably installed on the base assembly 1 .

[0085] In this embodiment, the detachable host structure includes a dryer main body and the host assembly 1 , and the dryer main body includes a bottom case. Wherein, the main body of the dryer includes the upper cover assembly 2, the base assembly 1, the support assembly and the drying cover 3 as described in Embodiment 1 or 2, and the bottom shell of the main body of the dryer is the base assembly 1 The bottom shell 11.

[0086] In this embodiment, the bottom of the bottom case 11 is provided with an installation cavity 111 opening downward, and the side wall of the installation cavity 111 is provided with a slider 112; the host assembly 7 includes a host housing 71, and the host housing T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap