Foldable double-end furrowing machine

A trench opener and trench opener technology, applied in the direction of excavation/covering trenches, planting methods, applications, etc., can solve the problems of low trenching efficiency, low moving efficiency, reduced work efficiency, reduced efficiency, etc., so as to reduce soil pressure. The effect of solid destruction, high work efficiency, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

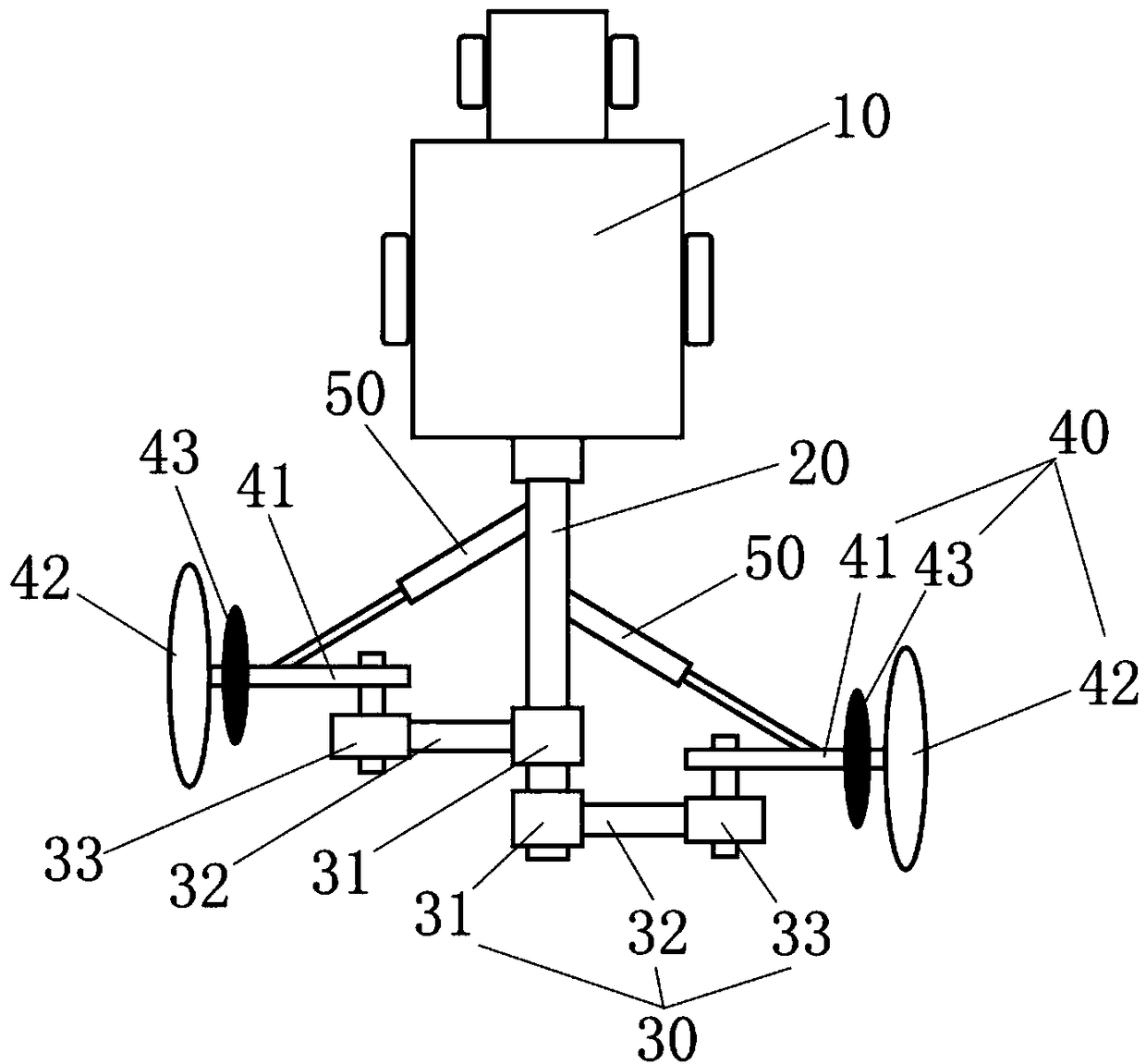

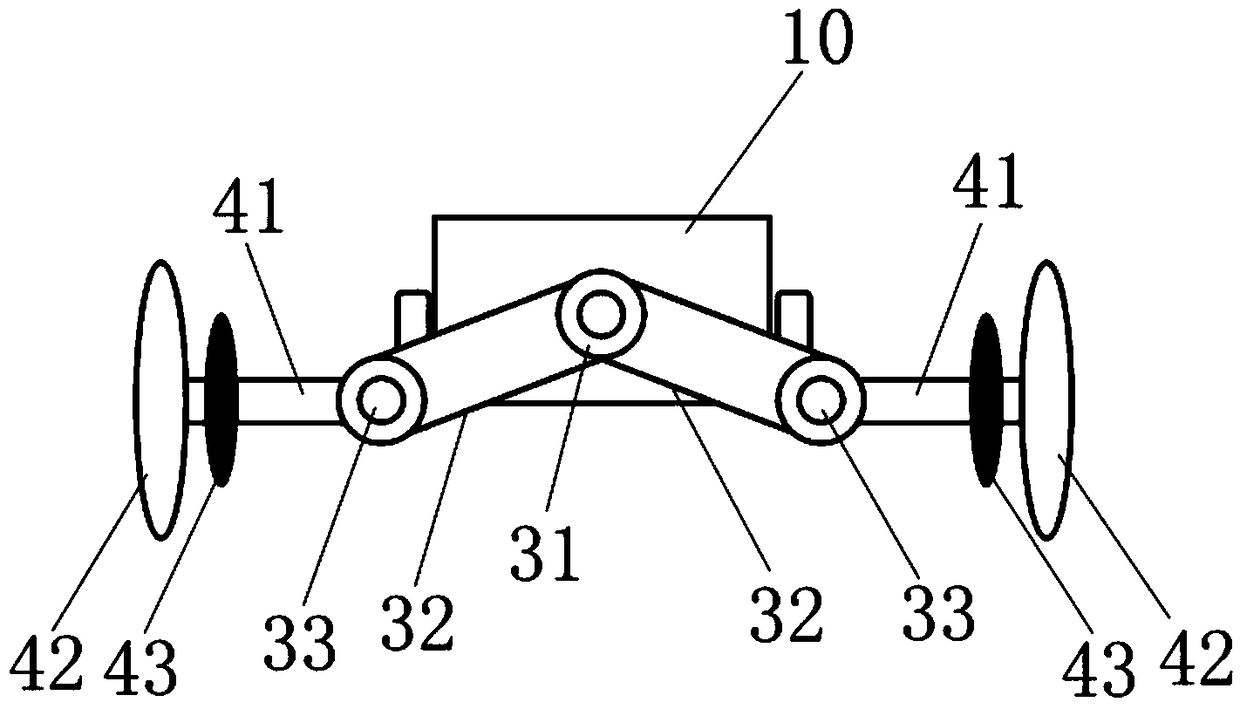

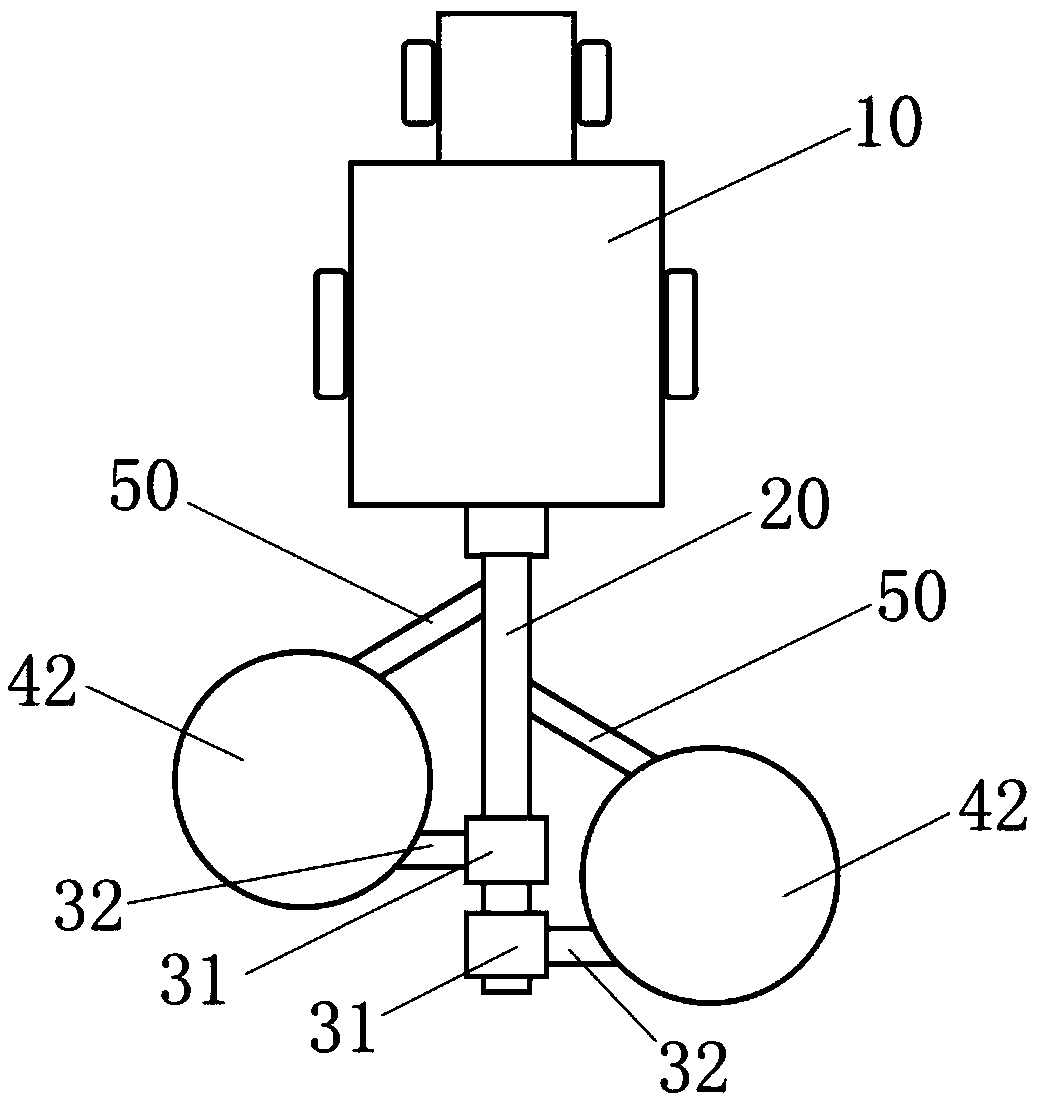

[0018] like figure 1 As shown, a foldable double-head trencher of the present invention includes a tractor 10 , an output shaft 20 , two transmission assemblies 30 , two trenching assemblies 40 and two folding assemblies 50 . The output shaft 20 is disposed at the rear end of the tractor 10, and the output shaft 20 is driven to rotate by the tractor. The two transmission assemblies 30 are respectively disposed on both sides of the output shaft 20 to be connected to the output shaft 20, the two ditching assemblies 40 are respectively rotatably connected to the two transmission assemblies 30, and the The axis of rotation of the ditch assembly 40 is perpendicular to the direction of the axis of rotation of the output shaft 20 , and the output shaft 20 drives the ditch assembly 40 to work through the transmission assembly 30 . The two ditching assemblies 40 work at the same time, effectively improving the ditching efficiency, and at the same time reducing the compaction damage to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap