Fabricated steel-concrete arch plate retaining wall

A concrete and prefabricated technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as the limitation of inclined piles, and achieve the effects of improved safety performance, low cost, and improved anchorage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

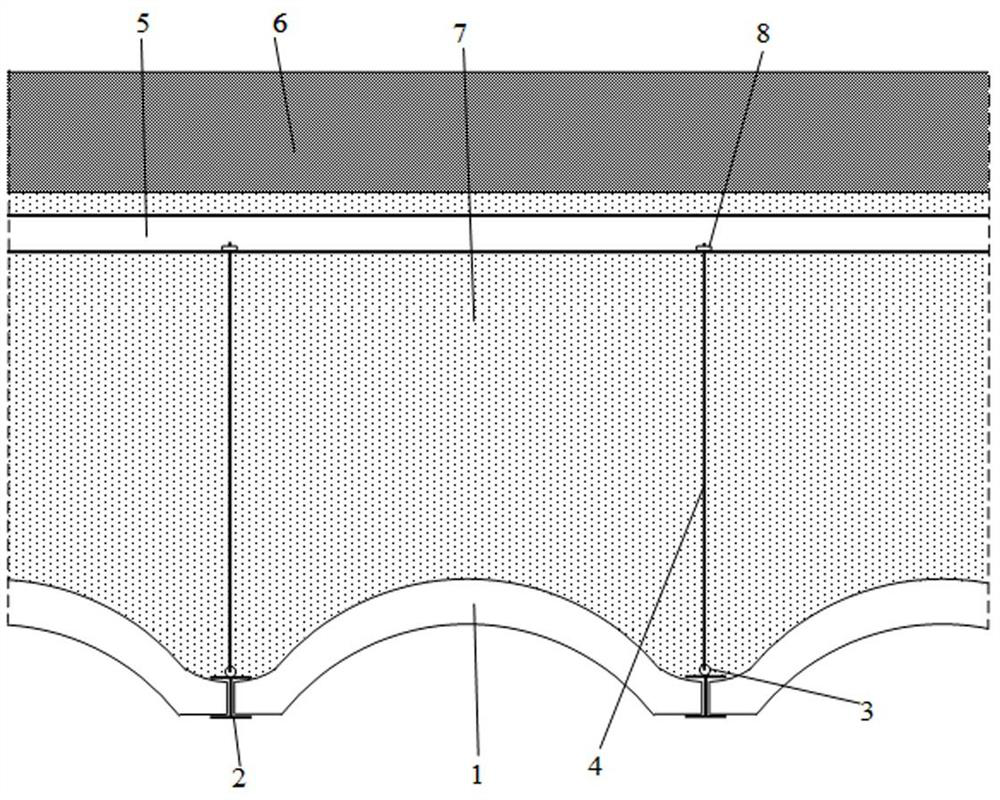

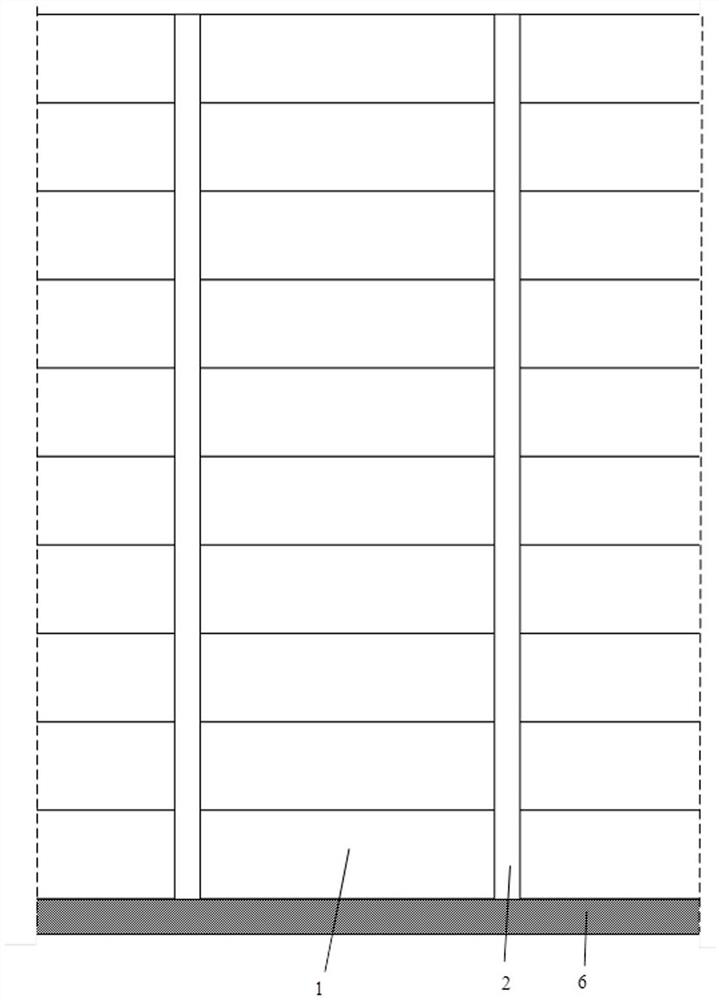

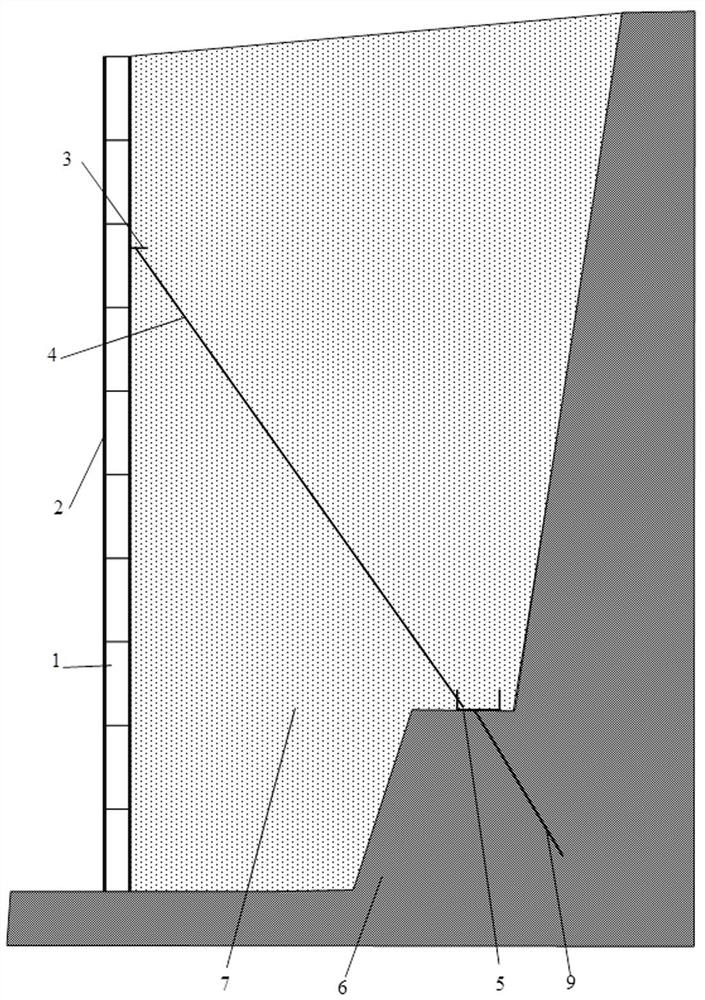

[0018] Such as Figure 1-3 Shown, the present invention a kind of prefabricated type steel concrete arch plate retaining wall, comprises concrete arch plate 1, H-shaped steel 2, steel ring 3, steel bar 4, channel steel 5, original soil 6, fill soil 7, nut 8 and The anchor rod 9 is provided with several layers of concrete arch plates 1 along the vertical direction on the original soil 6, and each layer is provided with several concrete arch plates 1.

[0019] Such as Figure 4 As shown, each concrete arch 1 is composed of a curved concrete arch 1-1 and two flat end plates 1-2, the flat end plates are located on both sides of the curved concrete arch, and the curved concrete arch 1-1 The horizontal projectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com