Clamping anchor with oblique section

A technology of oblique cutting surface and clamping piece, which is applied in the field of steel strand anchors, can solve the problems of reducing the number of repeated use of anchors, easy damage of anchors, and increasing production costs, so as to achieve stable anchoring, easy manufacture, and ensure safe production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

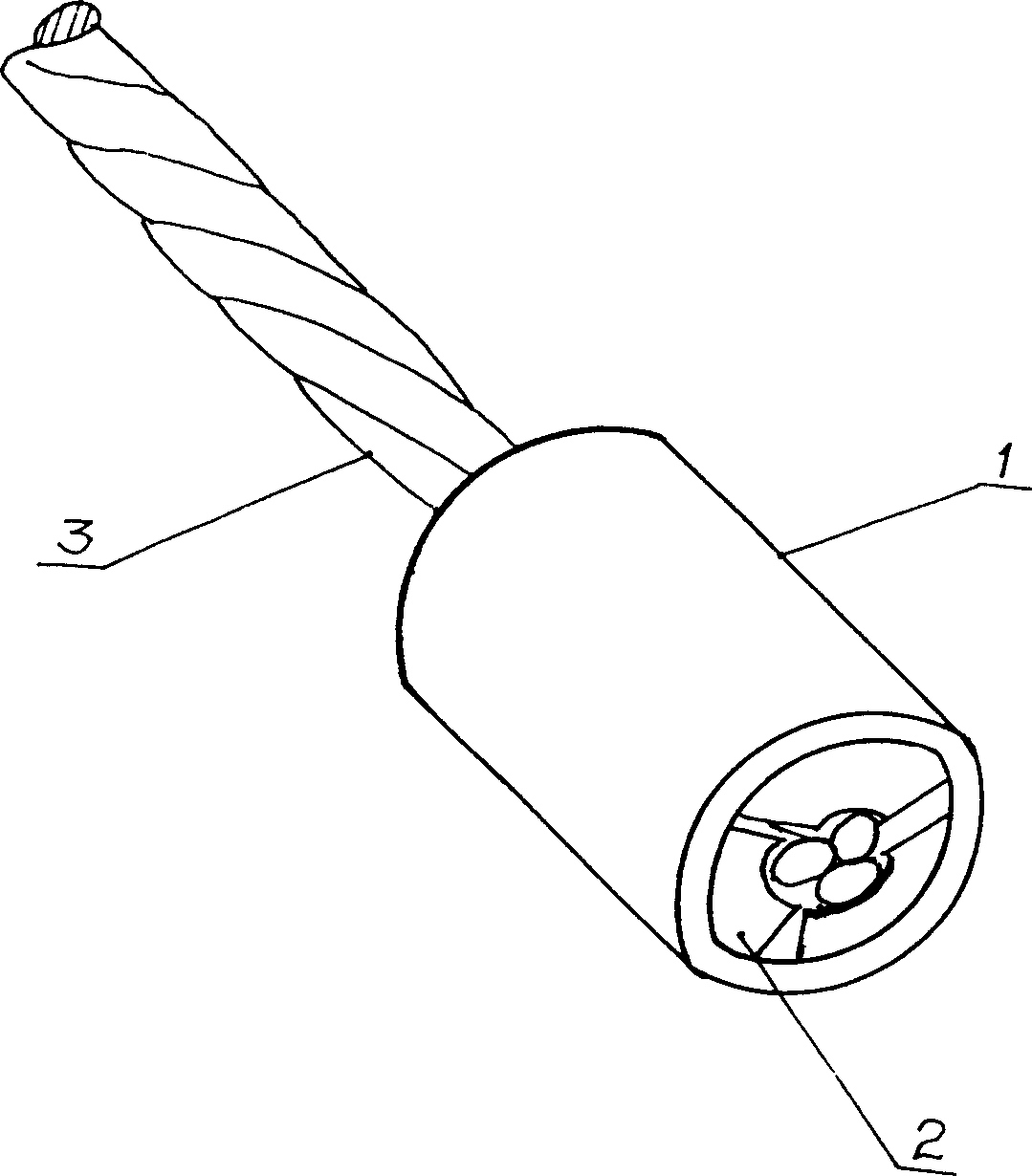

[0014] Such as figure 1 As shown, the anchor sleeve 1 of the bevel clip anchor is set on the end of the anchored steel strand 3, and the bevel clip 2 is inserted between the sleeve 1 and the strand 3, and the clip 2 The inner arc surface is closely attached to the twisted steel wire of the stranded wire 3 .

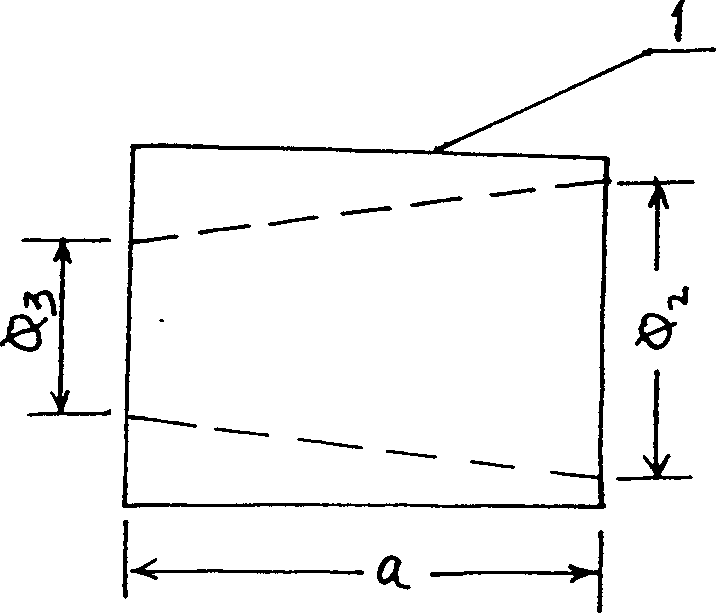

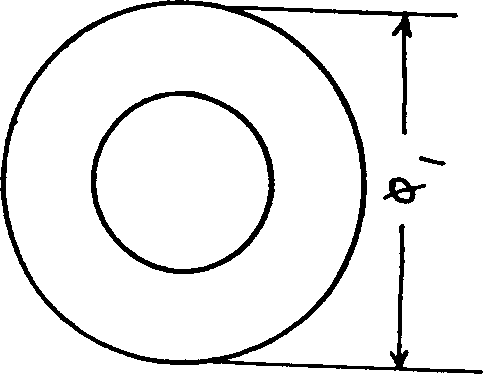

[0015] Such as figure 2 , 3 As shown in , 4, the anchor sleeve 1 is a steel cylinder with a conical cylindrical inner cavity, the length a=35-45mm, the outer diameter Φ1=25-30mm, the inner cavity of the sleeve is conical cylindrical, and the bottom is round Diameter Φ2 = 20-25mm, top circle diameter Φ3 = 10-15mm.

[0016] Such as Figure 5 , 6 , 7 and 8, the bevel clip 2 is an arc-shaped cone with longitudinal bevels on both sides, its length S is equal to that of the sleeve, the outer arc radius R1 at the bottom of the cone is 9-12mm, and the top Outer arc radius R2=6~8mm, long inner arc radius R3=3~5mm, transverse thread 7 is formed on the inner arc surface, a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com