Anchor clamping piece

A technology of clips and anchors, applied in structural elements, building components, building reinforcements, etc., can solve the disadvantage of clip follow-up and elastic deformation, reduce the occlusal force between clips and steel strands, and clip sliding wire, etc. problem, to improve the anchoring performance, increase the number of teeth, and prevent the clip from being bitten tightly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

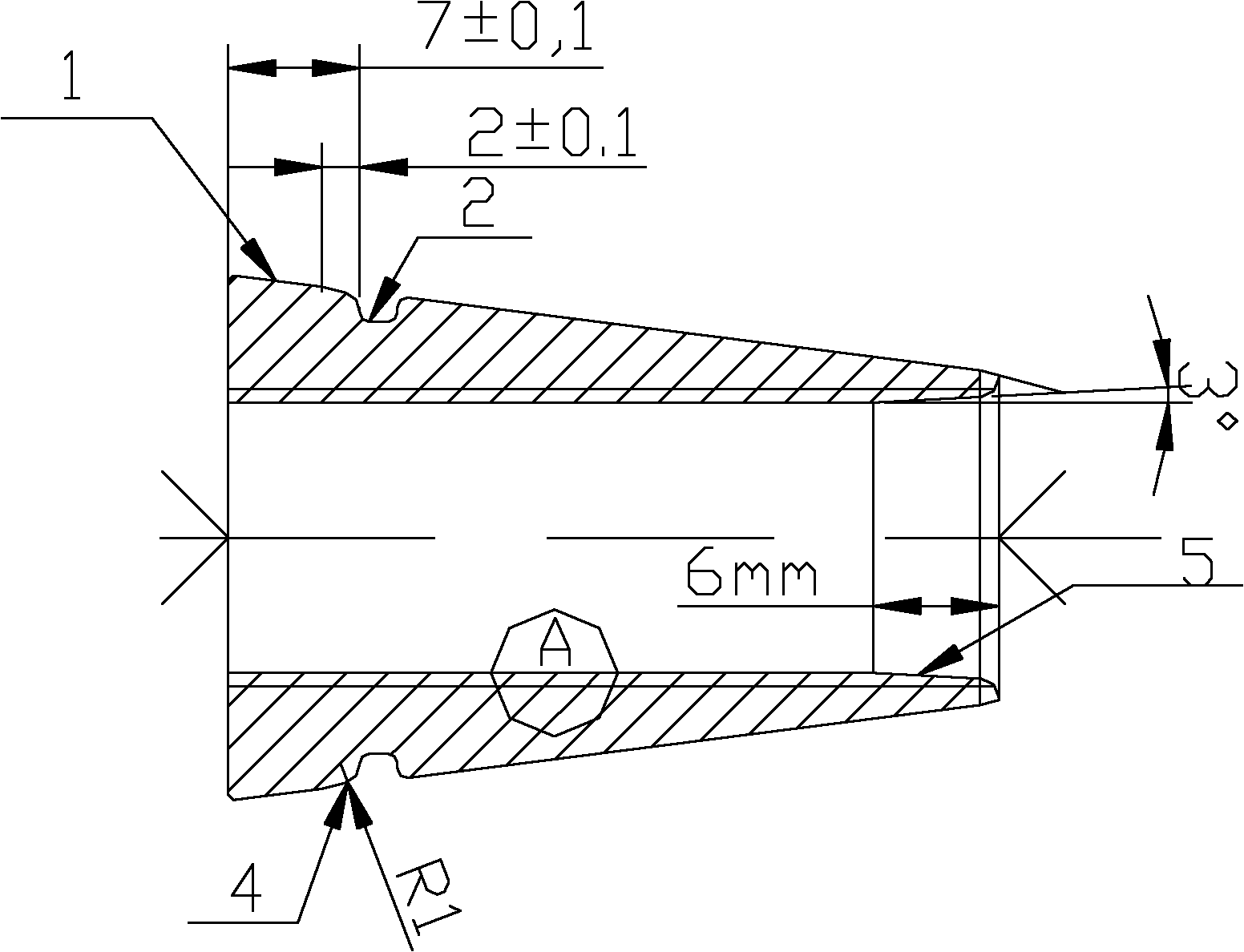

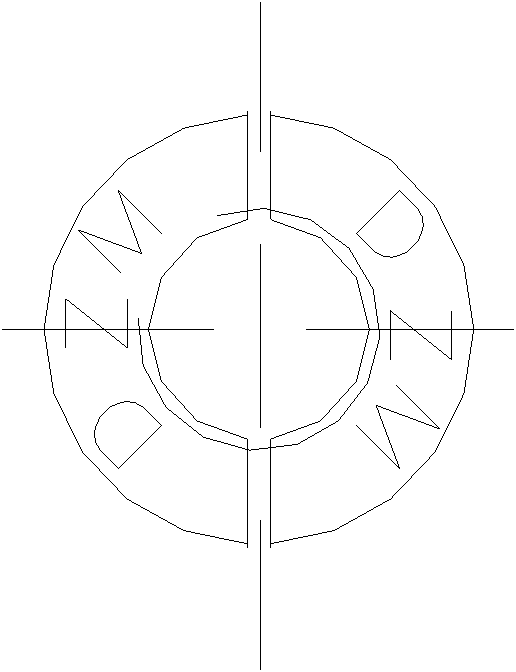

[0016] like figure 1 , 2 Shown: An anchor clip consisting of two clips. The small end surface to the large end surface of the clip is a conical surface 1, and the positioning groove 2 is located in the middle of the clip. Compared with the old clip, the positioning groove has moved down by 5mm. And both sides of the positioning groove are arc chamfered 4.

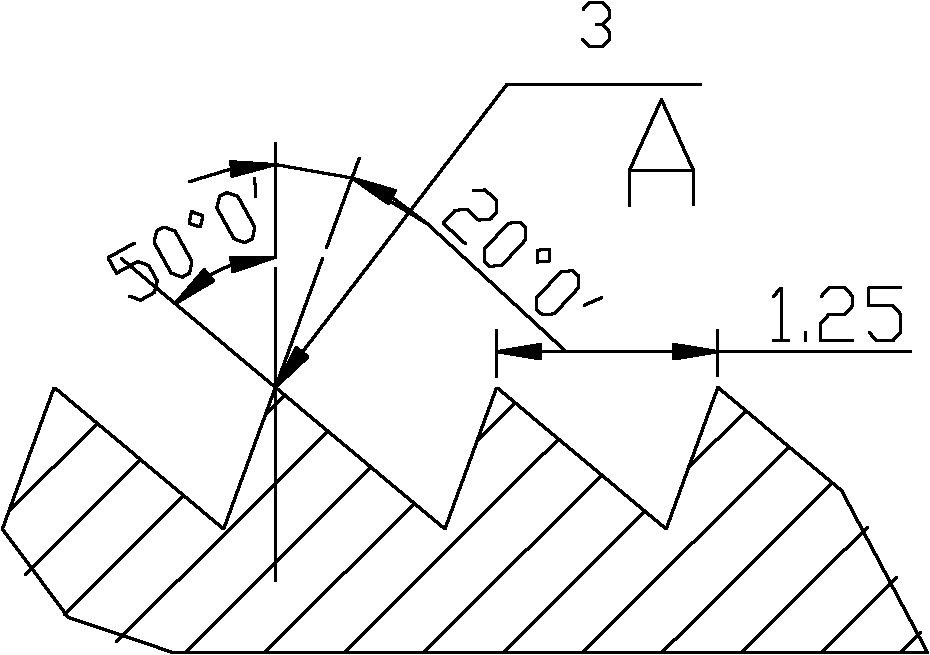

[0017] like image 3 Shown: the transition tooth 5 at the tail of the above-mentioned clip is a 3° arc chamfer, and the chamfer size is 6mm. The teeth 3 tooth shape of the clip is an inverted tooth shape, its tooth shape is 70°, and the tooth distance is 1.25mm (such as image 3 shown).

[0018] In this design, parameters such as the tooth profile angle and tooth pitch of the clip are selected reasonably, so as to ensure that the clip has sufficient bite force on the steel strand without excessive damage to the steel strand. It can effectively avoid the cracking, slipping and broken wires of anchor clips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com