Automatic horizontal milling machine

A milling machine, horizontal technology, applied in the field of automatic horizontal milling machines, can solve the problems of difficult and stable control of the moving speed of the worktable, affecting the processing efficiency, easy to damage the milling cutter, etc., to reduce the phenomenon of knife punching, ensure milling efficiency, and save electricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

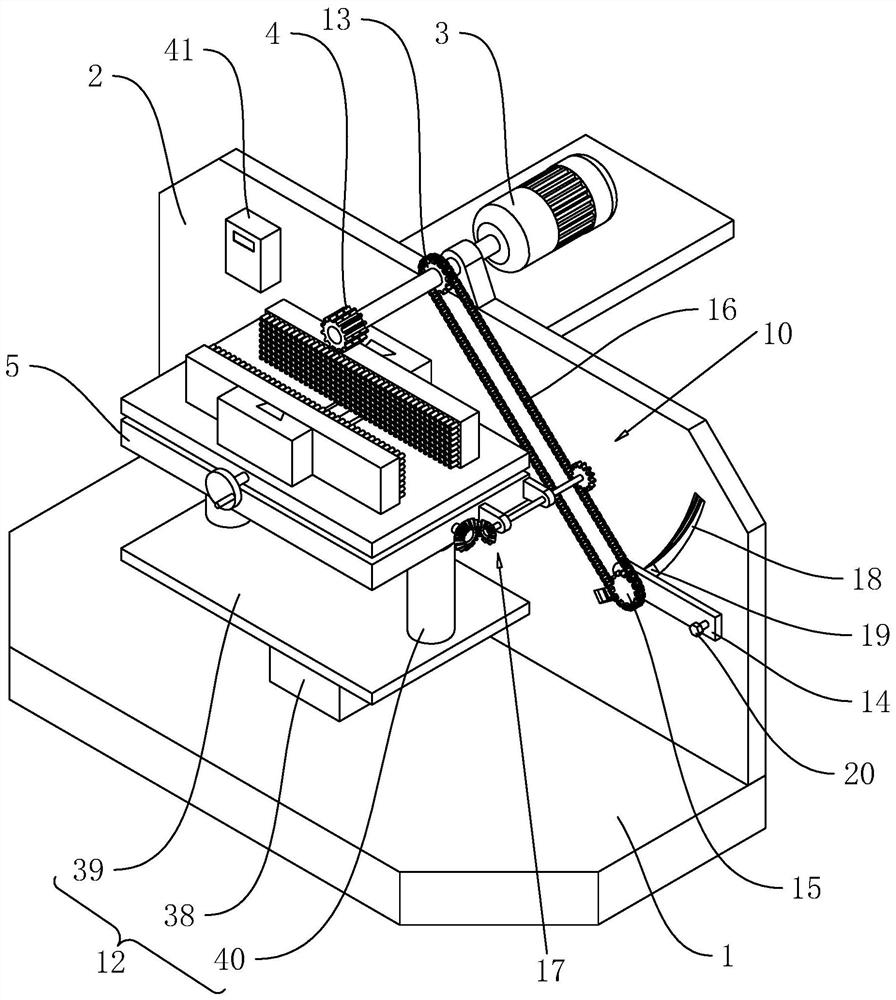

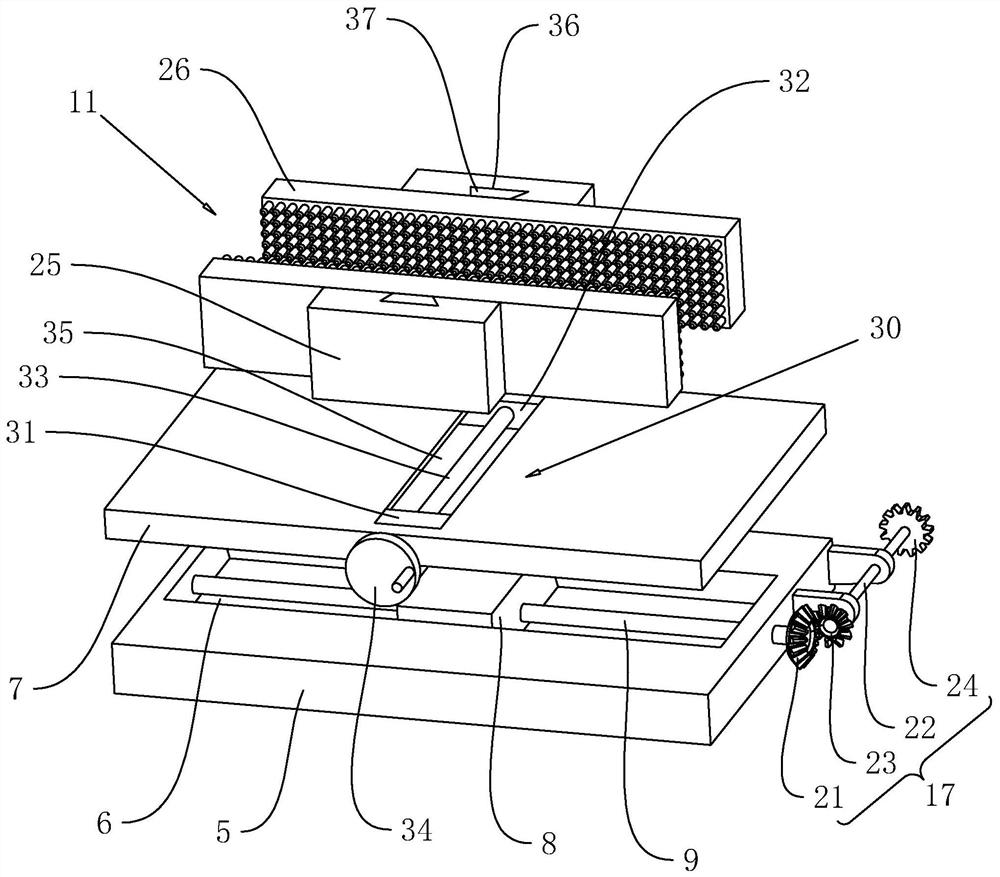

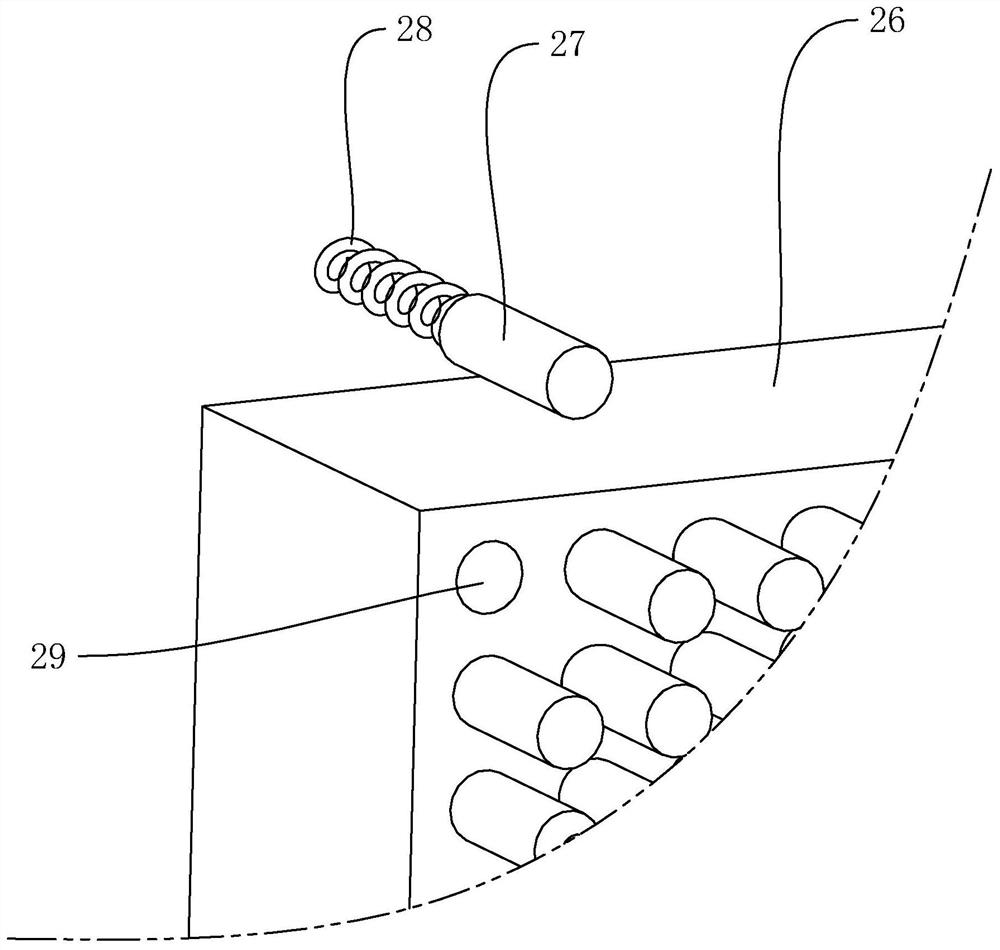

[0030] The following is attached Figure 1-3 The application is described in further detail.

[0031] The embodiment of the present application discloses an automatic horizontal milling machine.

[0032] refer to figure 1 , an automatic horizontal milling machine, including a base 1, a back plate 2 is fixed on the upper surface of the base 1 by welding, a servo motor 3 is arranged on the upper end of the back plate 2, and the servo motor 3 is fixed on the back plate 2 by bolts On the side wall of the back plate 2, the rotating shaft of the servo motor 3 is coaxially fixed with a milling cutter 4, and the side wall of the back plate 2 is fixed with a timing switch 41, and the timing switch 41 is electrically connected to the electric circuit of the servo motor 3.

[0033] refer to figure 1 , the top of the base 1 is provided with a mounting table 5, the mounting table 5 is located on the side of the back plate 2 away from the servo motor 3, the mounting table 5 is located belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com