Identification method of dynamic cutting force change characteristics of high-efficiency milling cutter

An identification method and cutting force technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as the absence of direct mapping relationship, the influence of dynamic cutting force of milling cutters, and the large differences in actual changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

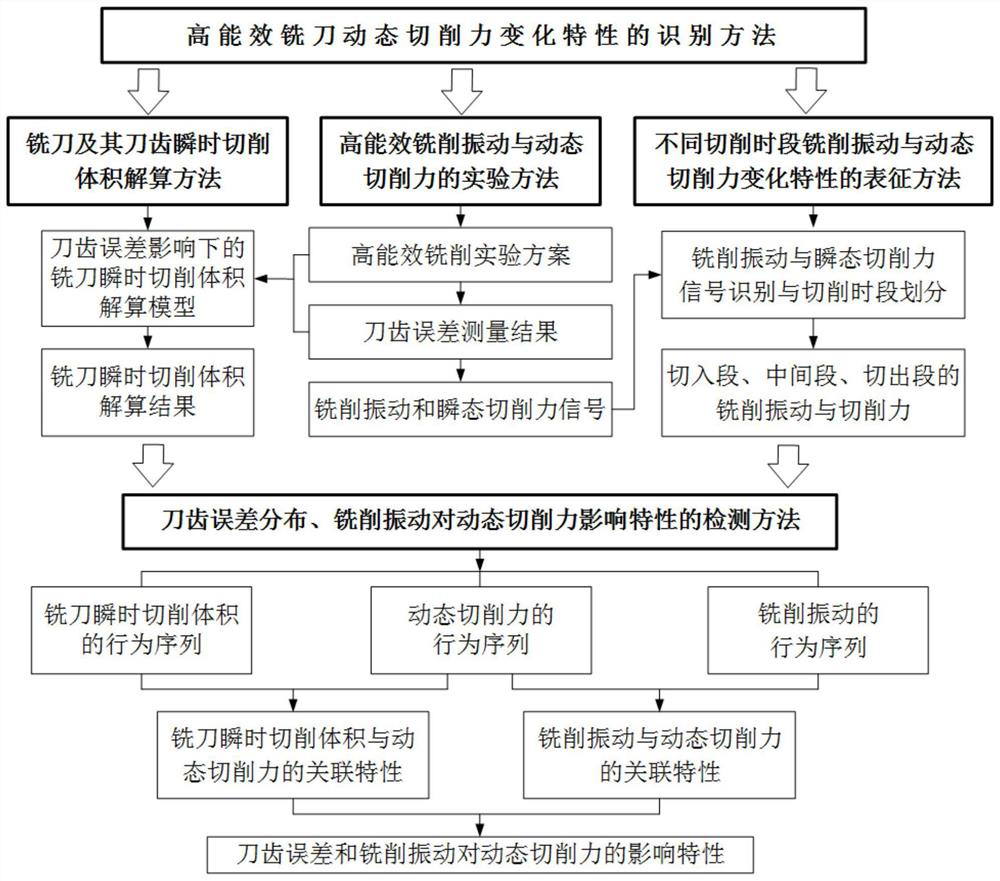

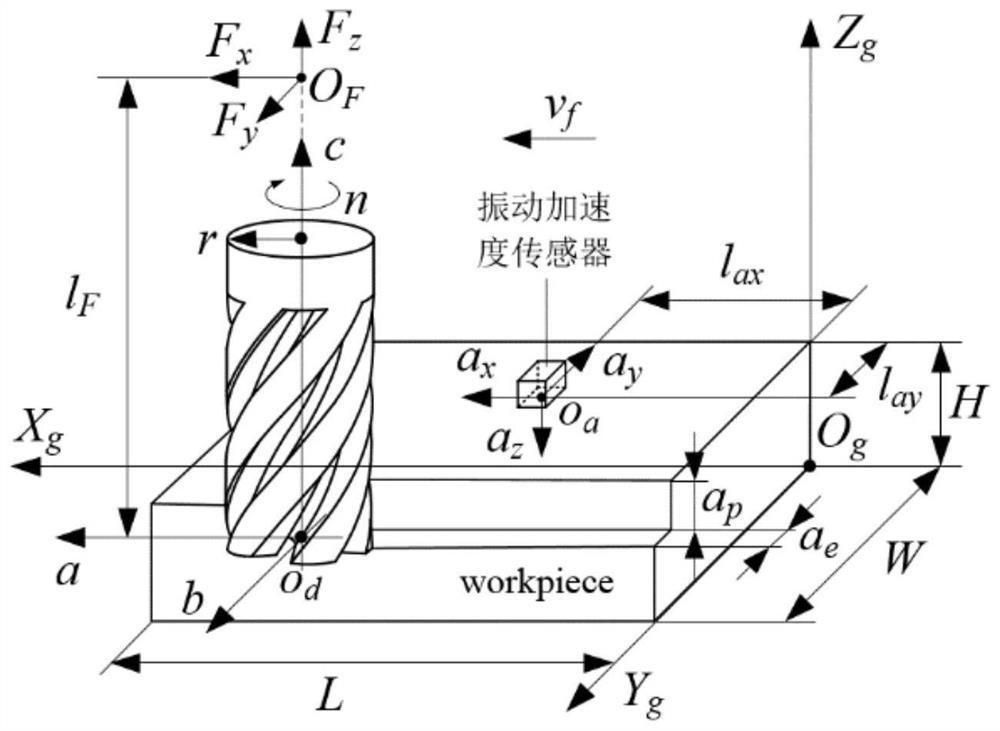

[0039] like figure 1 As shown, the present invention is an identification method of dynamic cutting force variation characteristics of high-efficiency milling cutters. In order to reveal the dynamic characteristics of milling vibration and cutting force, an identification method of milling vibration and dynamic cutting force variation characteristics is proposed. The method divides the entire cutting process into For the cut-in section, the middle section and the cut-out section, the milling vibration and dynamic cutting force curves of the above three cutting periods are obtained, so as to achieve the purpose of effectively correlating the milling vibration and the dynamic cutting force.

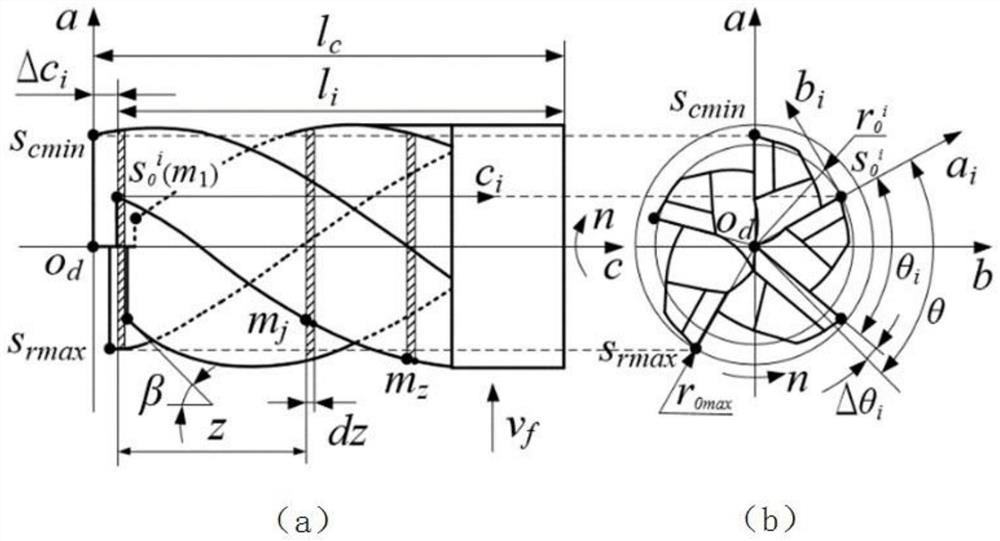

[0040] In order to reveal the change process of the instantaneous cutting volume, milling vibration and dynamic cutting force of the milling cutter in different cutting periods, a method for constructing the instantaneous cutting behavior sequence of the milling cutter is proposed. Distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com