Automatic tire blank conveying manipulator tire contact device

A technology of automatic conveying and manipulator, applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of damage to the embryo, falling into the embryo, exceeding and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

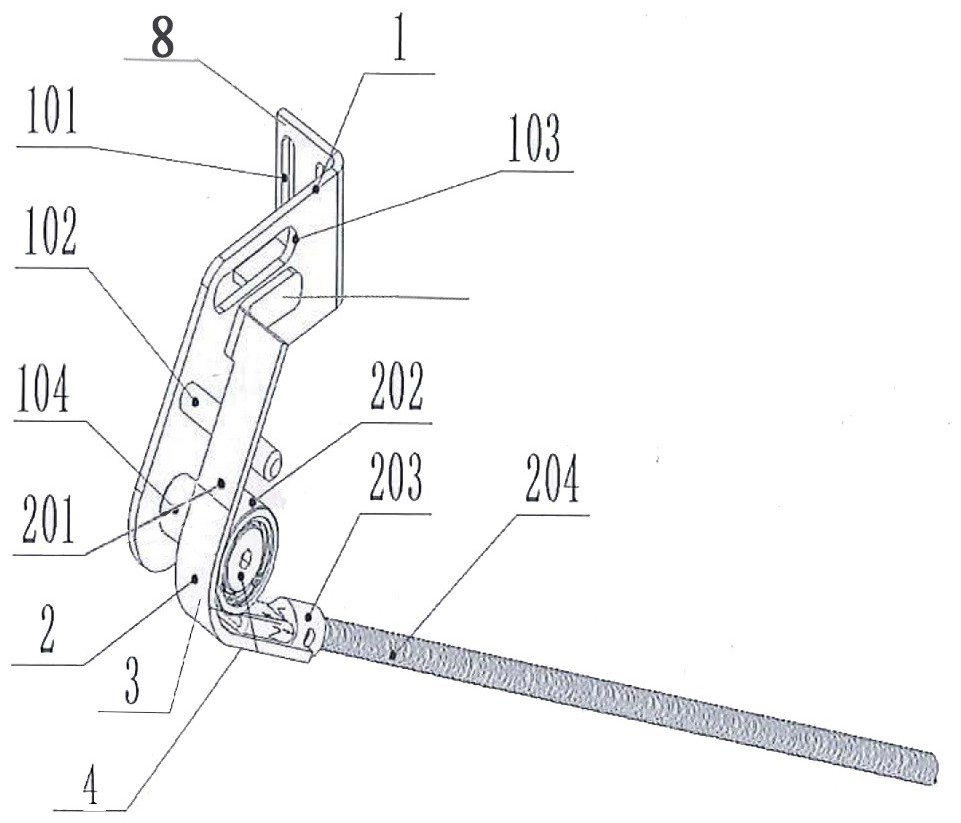

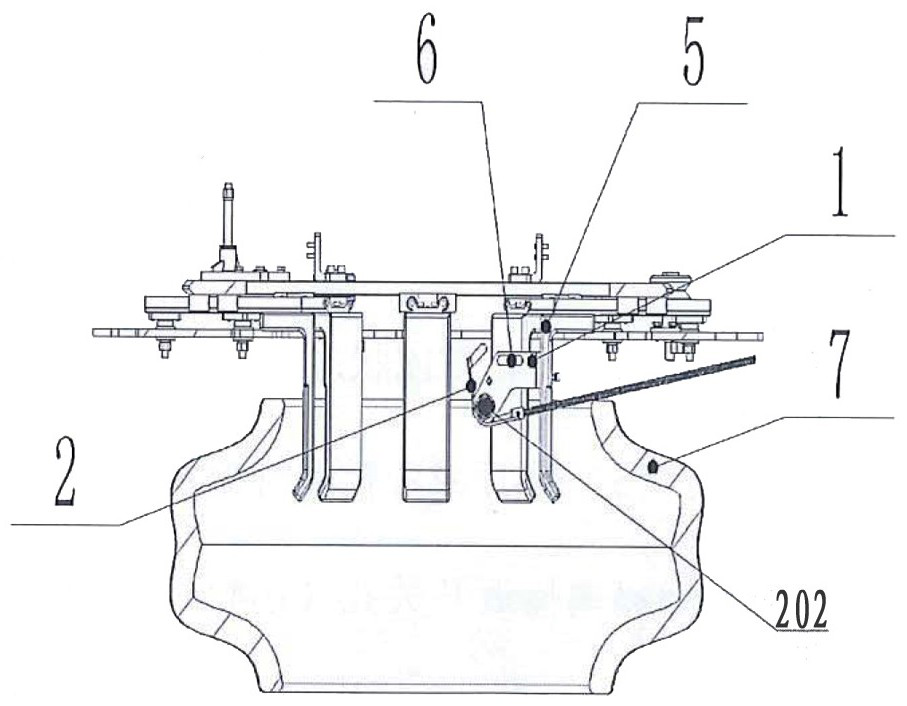

[0030] A tire contactor device for an automatic embryo conveying manipulator, comprising a bracket (1), a tension spring (204), and a tension spring tire contact lever (2); the tension spring tire contact lever (2) is formed by a long arm (3) An "L"-shaped rod formed by fixed connection with the short arm (4), the short arm (4) of the extension spring contact lever (2) and the extension spring (204) are welded to the transition tube at one end of the short arm (4) (203) connected; and located on the same straight line as the short arm (4); one end of the transition tube (203) is a flat tube, and the other end is a round tube, and the end of the flat tube is welded and fixed to the tension spring tire lever (2) Connected, the round tube end is connected with the extension spring (204); the extension spring is plugged into the round tube end, and the extension spring matches the diameter of the round tube.

[0031] One end of the bracket (1) is rotationally connected with the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com