Distributor of multi-bin carbonization device

A technology of carbonization device and distributor, which is applied in the direction of special dry distillation, petroleum industry, coke oven, etc., can solve the problem of not being able to meet the simultaneous supply, and achieve the effect of eliminating material accumulation and bonding, ensuring high efficiency, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

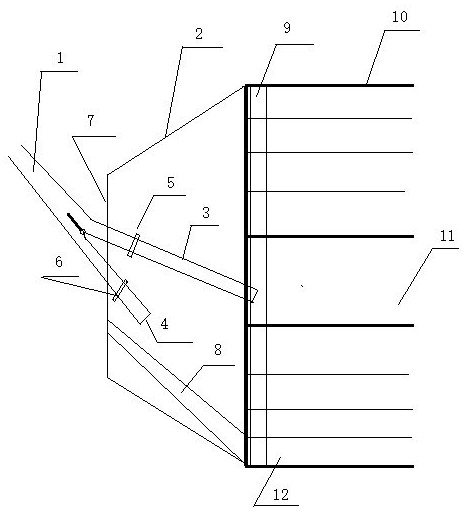

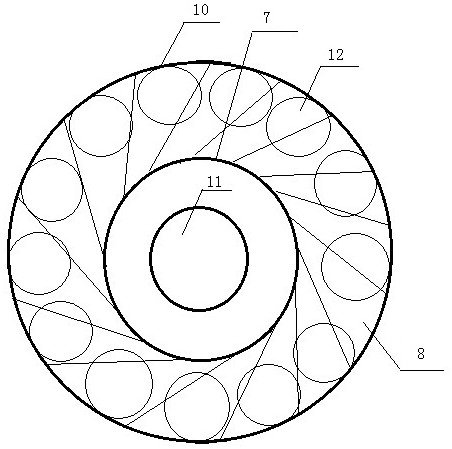

[0020] figure 1 Shown is a distributor of a multi-chamber carbonization device, which includes a feeding pipe, a feeding module and a sealing ring. The lower end of the feeding pipe is provided with a feeding sub-pipe 1 and a feeding sub-pipe 2, and the feeding pipe is statically fixed and extends into the feeding module. The material enters the carbonization device in two ways, one way of material enters the intermediate carbonization chamber (11) for carbonization through the feeding branch 1, and the other way of material enters the carbonization chamber (12) through the feeding pipe 2 through the feeding trough for carbonization.

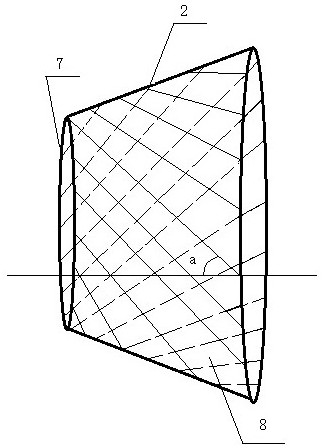

[0021] The feeding module is connected with the carbonization device through a sealing ring. There is a feeding trough inside the feeding module. The feeding trough is connected with multiple carbonization bins one by one. The inclination angle α is 20º~80º, which can effectively ensure the uniformity of the material distribution process. , to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap