Multi-dimensional stereoscopic embroidery and manufacturing method thereof

A three-dimensional, embroidery technology, applied in the field of multi-dimensional three-dimensional embroidery and its production, can solve the problems of difficult embroidery process, high embroidery level requirements for embroidery friends, and embroidery products are difficult to show three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

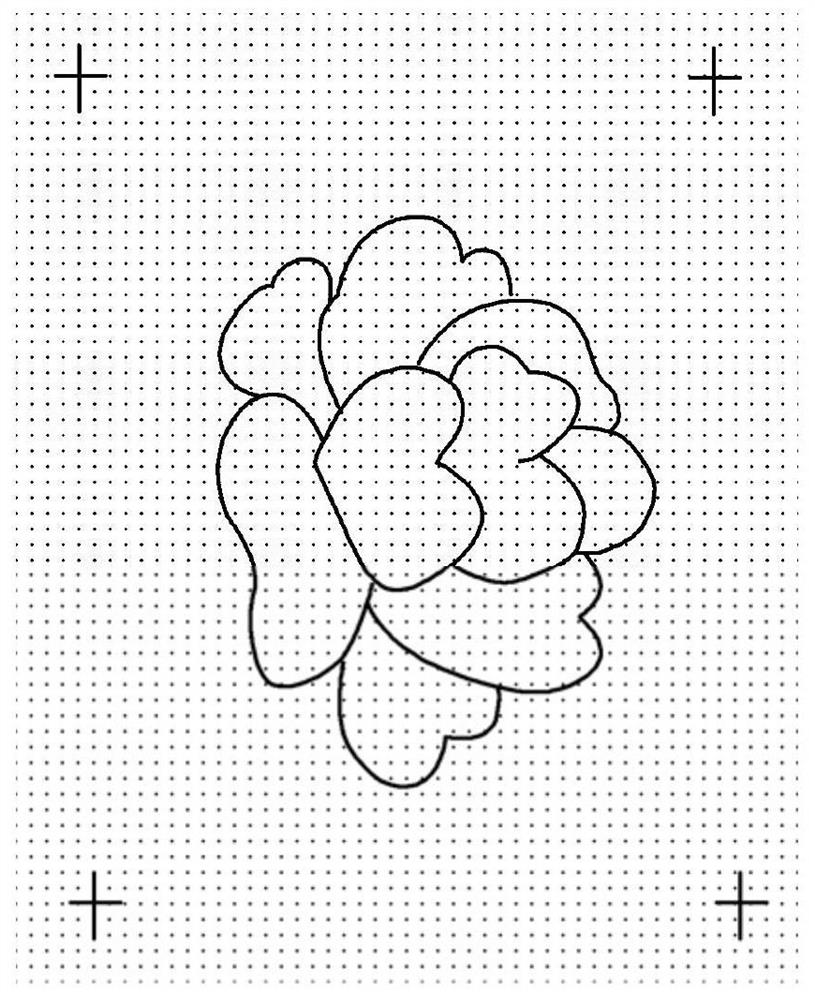

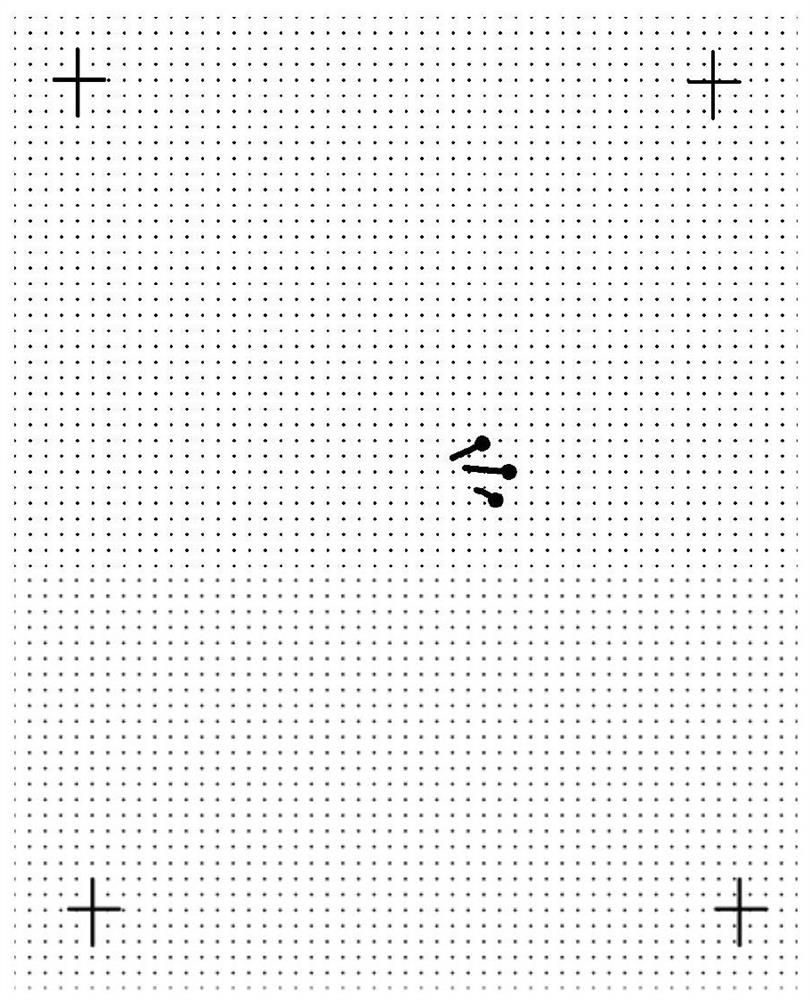

[0037] A multi-dimensional three-dimensional embroidery, which is embroidered with multiple double-effect water-soluble cloths. A pattern is designed into multiple layers by computer, and the designed pattern of each layer is printed on different double-effect cloths with water-soluble ink. On the water-soluble cloth, print four "ten" characters on the positions corresponding to the four corners of each embroidered cloth as a unified positioning line. Production method: first put the first double-effect water-soluble cloth on the fabric to be embroidered, embroider by hand according to the pattern on the first double-effect water-soluble cloth, and then cover the first double-effect water-soluble cloth with the newly embroidered On the embroidery thread, align the position according to the unified positioning line, then manually embroider according to the pattern on the second double-effect water-soluble cloth, and then repeat the above operation until the pattern on the last d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com