Manufacturing method of air-permeable shell fabric with suede effect

A manufacturing method and air permeability technology, which are applied in the field of air permeable surface cloth manufacturing, can solve the problems of impossible suede, peculiar smell, and poor ventilation effect of the cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

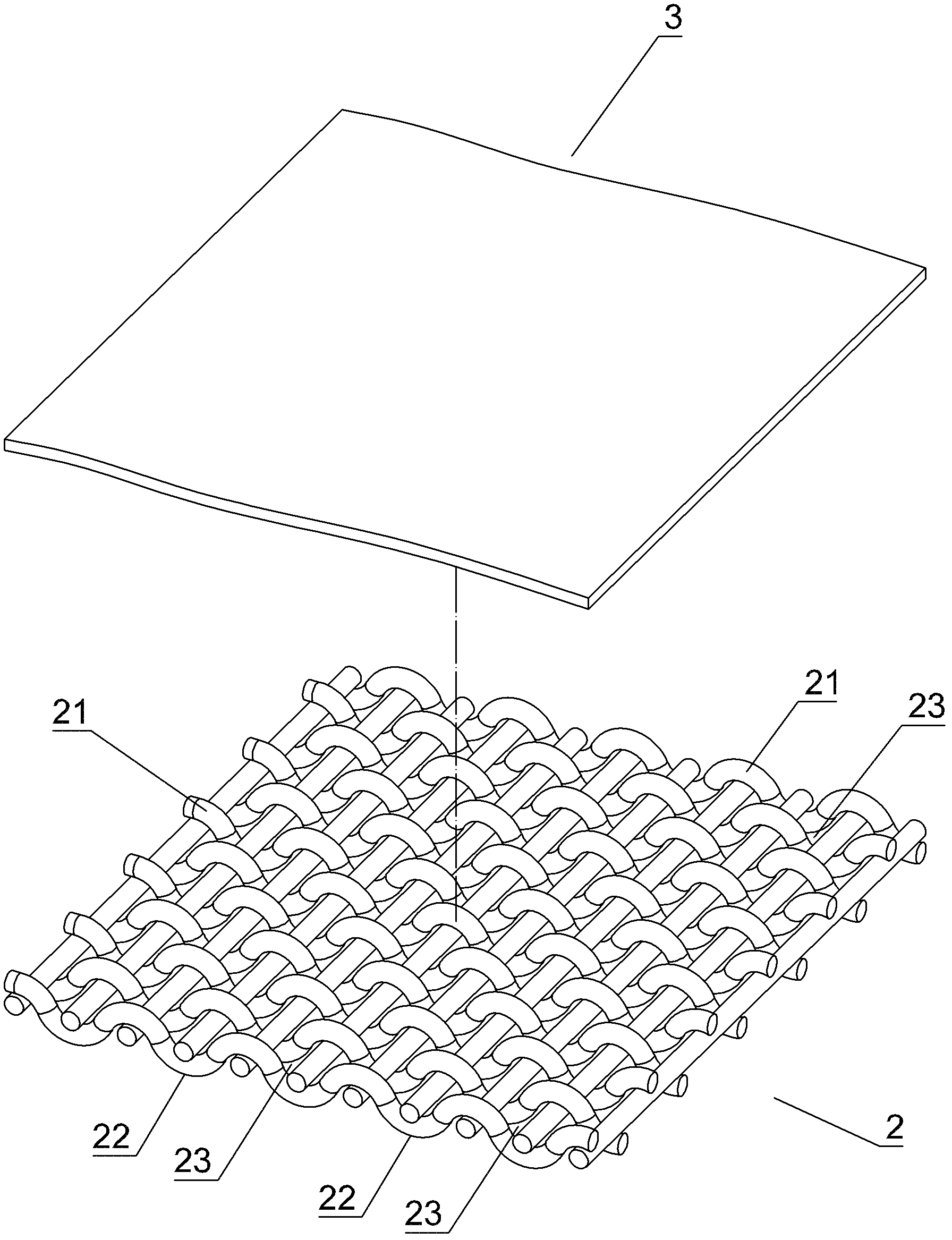

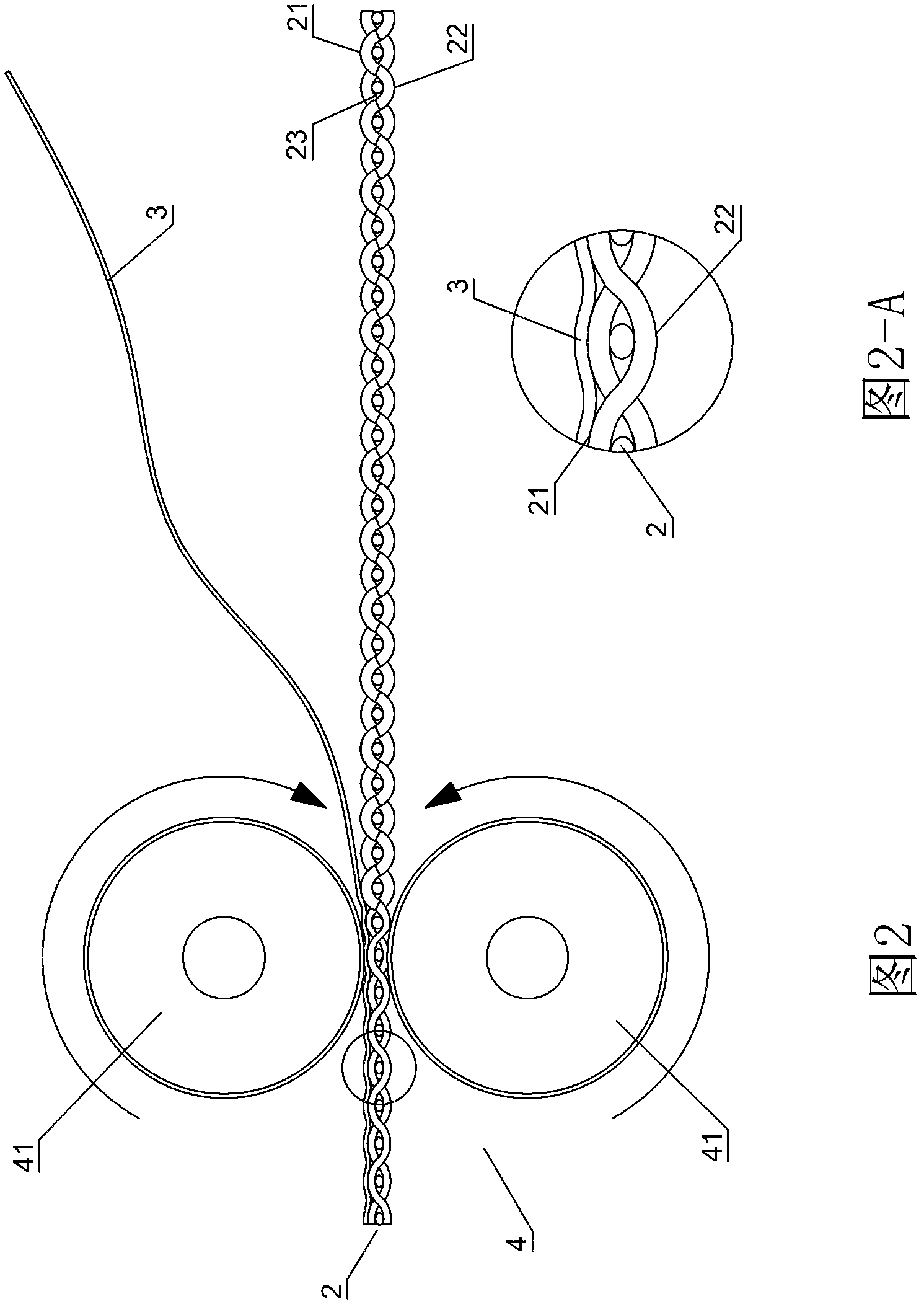

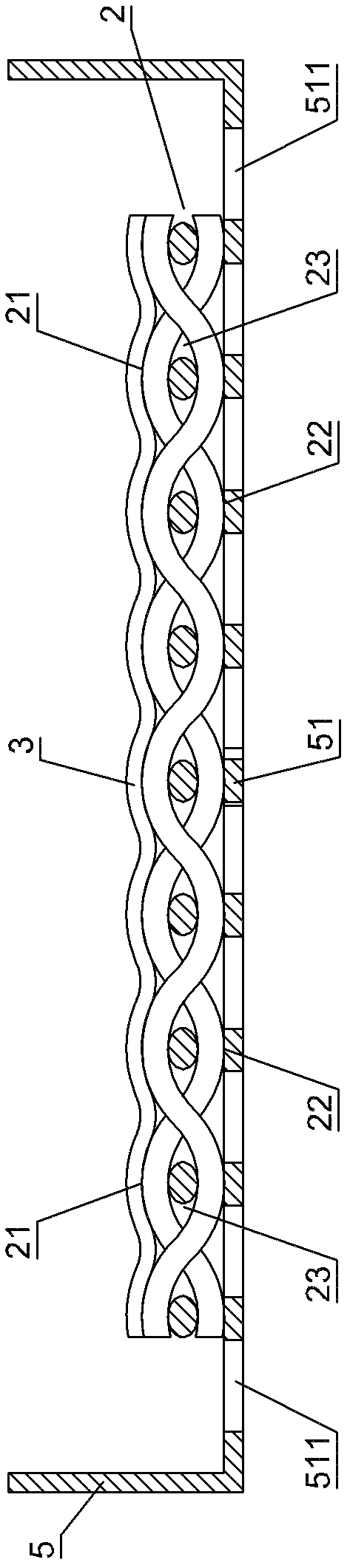

[0032] see Figure 1 to Figure 4 and figure 2 -As shown in -A, a film layer 3 is coated on the upper surface 21 of a metal mesh 2. The film layer 3 can be made of thermoplastic polyurethane elastomer resin (Thermoplastic Polyurethane) or other thermoplastic resins through extrusion molding or spraying. The membrane method is made into a thin film; it is first temporarily pasted on the upper surface 21 of the metal mesh 2 by a temporary bonding device 4. The temporary bonding device 4 can be a hot roller 41, a high-frequency machine, an ultrasonic instrument, etc. The integrated metal mesh 2 and film layer 3 are placed on the chassis 51 of a plastic-absorbing mold 5, and the chassis 51 offers several suction holes 511. Soften the film layer 3, and then carry out vacuum suction to the film layer 3 by passing through the mesh 23 from bottom to top, so as to impel the film layer 3 above the mesh 23 to be strongly sucked, and then form broken whiskers 31 and Perforated holes 32,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com