Multifunctional bare concrete surface protection coating material and preparation method thereof

A clear-faced concrete and multi-functional technology, applied in the direction of coating, etc., can solve the problems of high requirements for oil-based fluorocarbon paint, easy to pollute the environment, and high cost, and achieve good low-temperature flexibility, good pollution resistance, and excellent weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

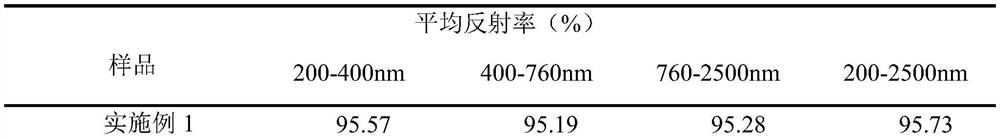

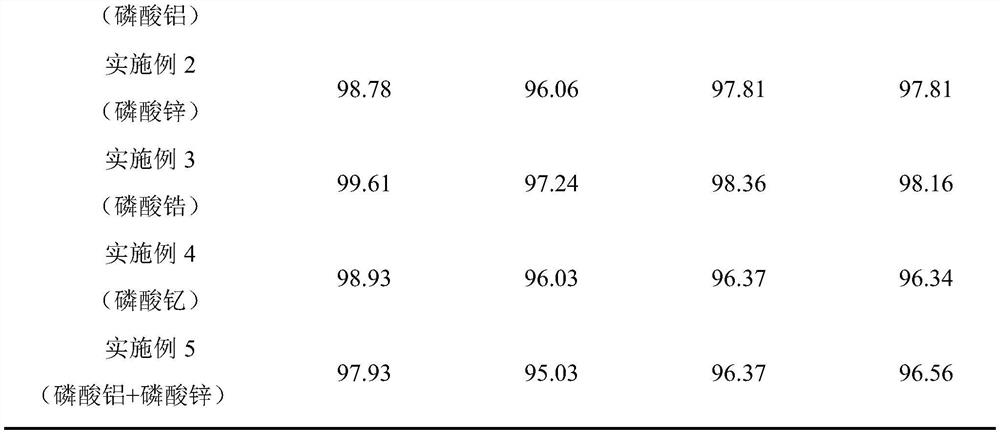

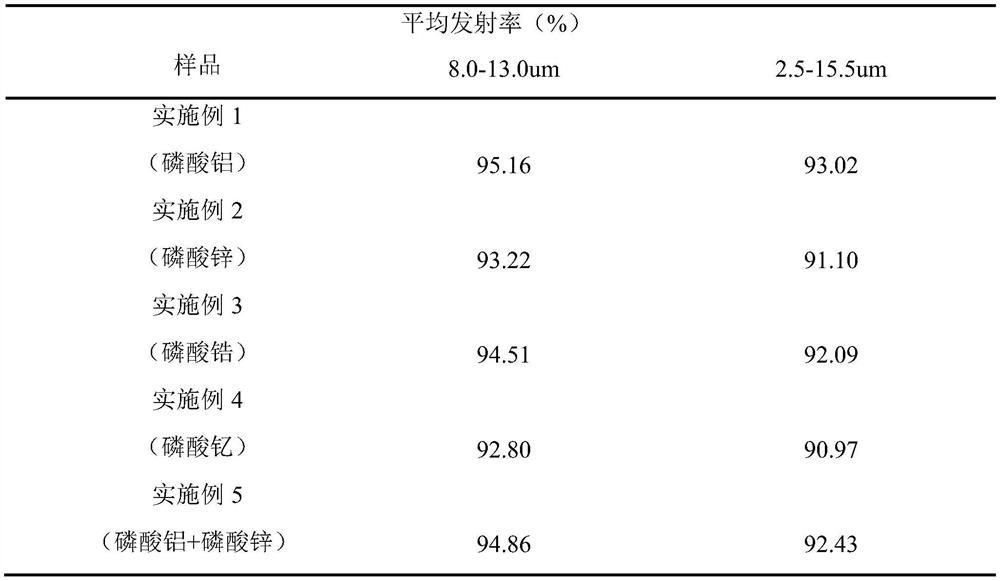

Embodiment 1

[0037] The present embodiment provides a kind of multifunctional fair-faced concrete surface protection coating material, and it comprises following raw material by weight: 33 parts of water-based fluorosilicon modified acrylic resins, 25 parts of spherical nano-aluminum phosphates, 1.5 parts of silane coupling agents, solid 15 parts of alkaline silica sol with a content of 30%, 2 parts of BYK-2015 water-based wetting and dispersing agent, 1.5 parts of Optiflim 400 water-based film-forming aid, 1 part of Tego810 water-based defoamer, 1.5 parts of RM-2020NPR water-based thickener , 1 part of BYK-348 water-based leveling agent, 20 parts of deionized water.

[0038] Its preparation process is as follows:

[0039] S1: Put the spherical nano-aluminum phosphate in an oven and dry at 140°C for 1 hour, dissolve the silane coupling agent KH-450 in 50% ethanol solution, stir evenly, add to the dried spherical nano-aluminum phosphate, and stir on a high-speed disperser And heated to a c...

Embodiment 2

[0044] The present embodiment provides a kind of multifunctional fair-faced concrete surface protection coating material, and it comprises following raw material by weight: 36 parts of water-based fluorosilicon modified acrylic resins, 27 parts of nano-zinc phosphates, 1.5 parts of silane coupling agents, solid content 13 parts of 30% alkaline silica sol, 2 parts of BYK-154 water-based wetting and dispersing agent, 1.75 parts of LOXANOL EFC 300 water-based coalescent, 0.5 parts of Dispelair CF 481 water-based defoamer, Cognis DSX 3551 water-based thickener 1.5 parts, Borchi Gel0625 water-based leveling agent 0.75 parts, deionized water 18 parts.

[0045] Its preparation process is as follows:

[0046] S1: Put nano-zinc phosphate in an oven and dry at 140°C for 1 hour, dissolve silane coupling agent KH-460 in 50% ethanol solution, stir evenly, add to dried nano-zinc phosphate, stir and heat on a high-speed disperser To a certain temperature, after the reaction, filter with suc...

Embodiment 3

[0051] The present embodiment provides a kind of multifunctional fair-faced concrete surface protection coating material, and it comprises following raw material by weight: 42 parts of water-based fluorosilicon modified acrylic resins, 32 parts of nano zirconium phosphates, 1.6 parts of silane coupling agents, solid content 12 parts of 40% alkaline silica sol, 1.5 parts of OROTAN 963 water-based wetting and dispersing agent, 2 parts of DAPRO FX 513 water-based film-forming aid, 0.75 parts of BYK-034 water-based defoamer, 0.75 parts of COAPUR 4435 water-based thickener , 1 part of ACRYSOLRM-2020NPR water-based leveling agent, 8 parts of deionized water.

[0052] Its preparation process is as follows:

[0053] S1: Put the nano-zirconium phosphate in an oven and dry at 140°C for 1 hour, dissolve the silane coupling agent KH-550 in 50% ethanol solution, stir evenly, add to the dried nano-zirconium phosphate, stir and heat on a high-speed disperser After reaching a certain tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com