Remote monitoring automatic refueling device

A technology of automatic refueling and remote monitoring, applied in the directions of engine components, engine lubrication, and lubricating parts, etc., can solve the problems of oil residue clogging of the filter screen, affecting the refueling efficiency, etc., to prevent clogging and accelerate the falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

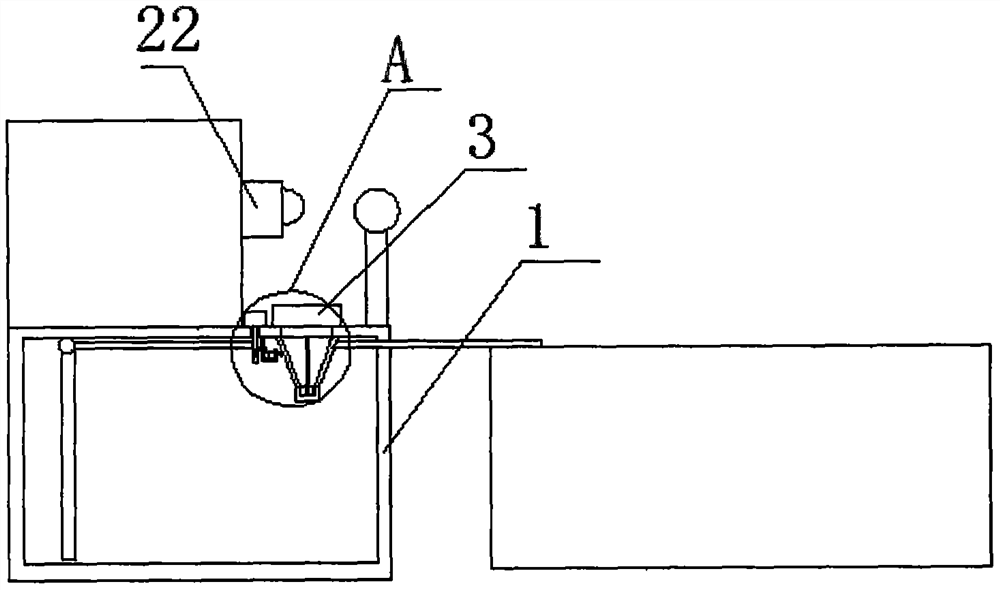

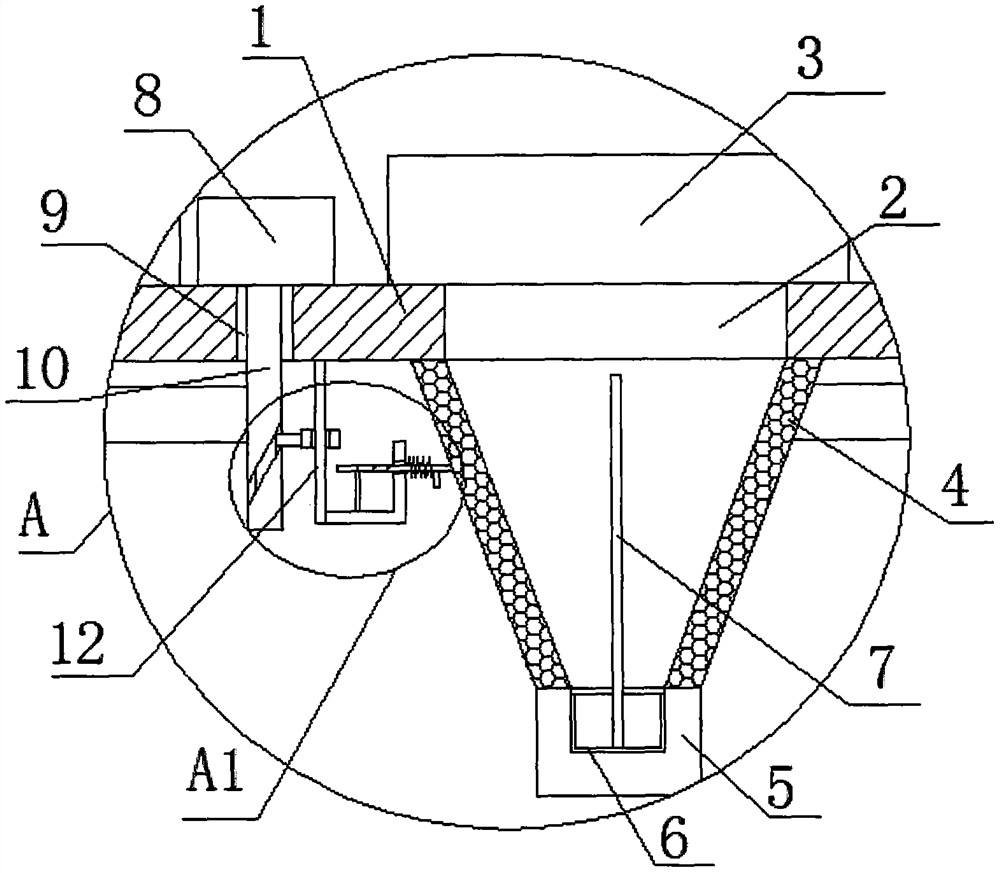

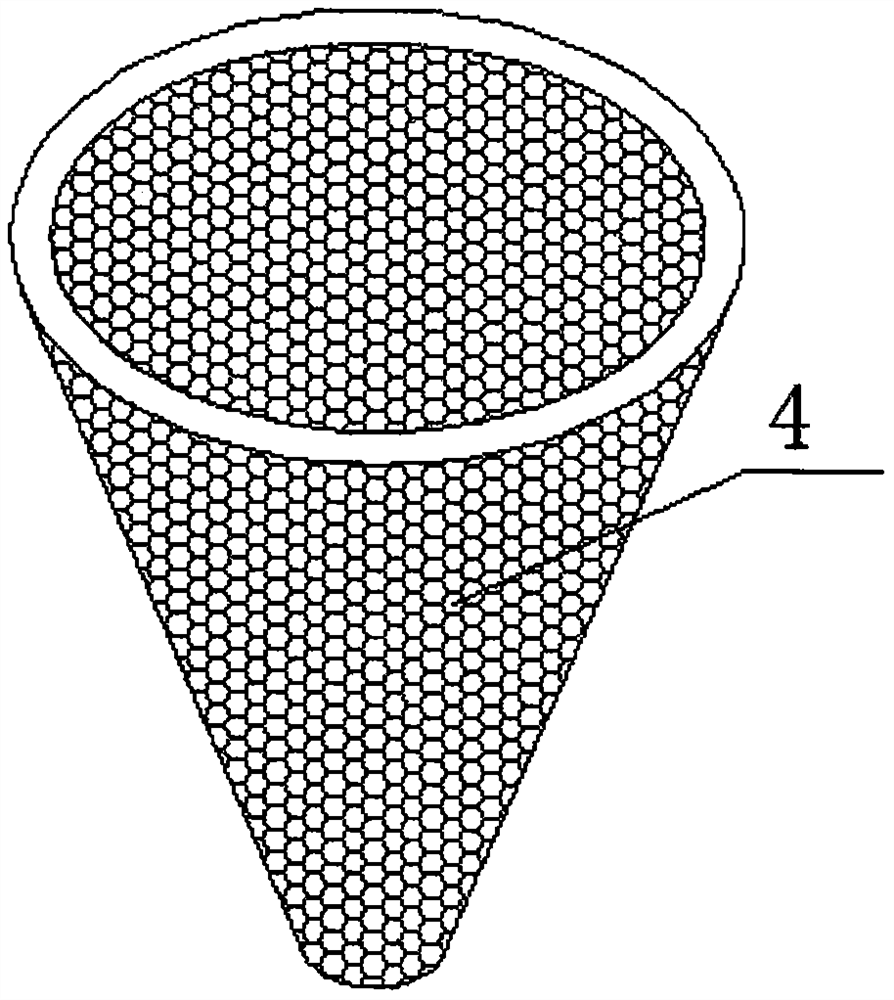

[0021]ReferenceFigure 1-4, A remote monitoring and automatic refueling device, including a fuel storage tank 1, a control box is arranged above the fuel storage tank 1, a fuel filler 2 is provided on the inner wall of the top side of the fuel storage tank 1, and a fuel tank cover 3 is provided above the fuel filler 2, a control box A camera 22 is fixedly installed on one side of the oil storage tank 1, a conical filter 4 is fixedly installed on the inner wall of the top side of the oil storage tank 1, the fuel filler 2 is located in the conical filter 4, and a fixed box is fixedly installed on the bottom side of the conical filter 4 5. A collection box 6 is placed in the fixed box 5. A pull rod 7 is fixedly installed on the inner wall of the bottom side of the collection box 6. The top end of the pull rod 7 extends into the cone-shaped filter screen 4, and the fuel tank cover 3 is opened to the fuel storage tank 1. Fill in the oil, the oil enters the conical filter 4 through the ref...

Embodiment 2

[0027]ReferenceFigure 1-4, A remote monitoring and automatic refueling device, including a fuel storage tank 1, a control box is arranged above the fuel storage tank 1, a fuel filler 2 is provided on the inner wall of the top side of the fuel storage tank 1, and a fuel tank cover 3 is provided above the fuel filler 2, a control box A camera 22 is fixedly installed on one side of the oil storage tank 1, a tapered filter 4 is fixedly installed on the inner wall of the top side of the oil storage tank 1, the fuel filler 2 is located in the tapered filter 4, and the bottom side of the tapered filter 4 is fixedly welded with a fixed box 5. A collection box 6 is placed in the fixed box 5. A pull rod 7 is fixedly welded on the bottom inner wall of the collection box 6. The top end of the pull rod 7 extends into the conical filter screen 4, and the fuel tank cover 3 is opened to the fuel storage tank 1. Fill in the oil, the oil enters the conical filter 4 through the refueling port 2, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com