Rotary circulation type track-driven IC card packaging robot

A rotary drive and circulation technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex structure, reduced working reliability, and high manufacturing cost, so as to simplify the mechanism, reduce manufacturing cost, and improve reliability. Sexuality and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

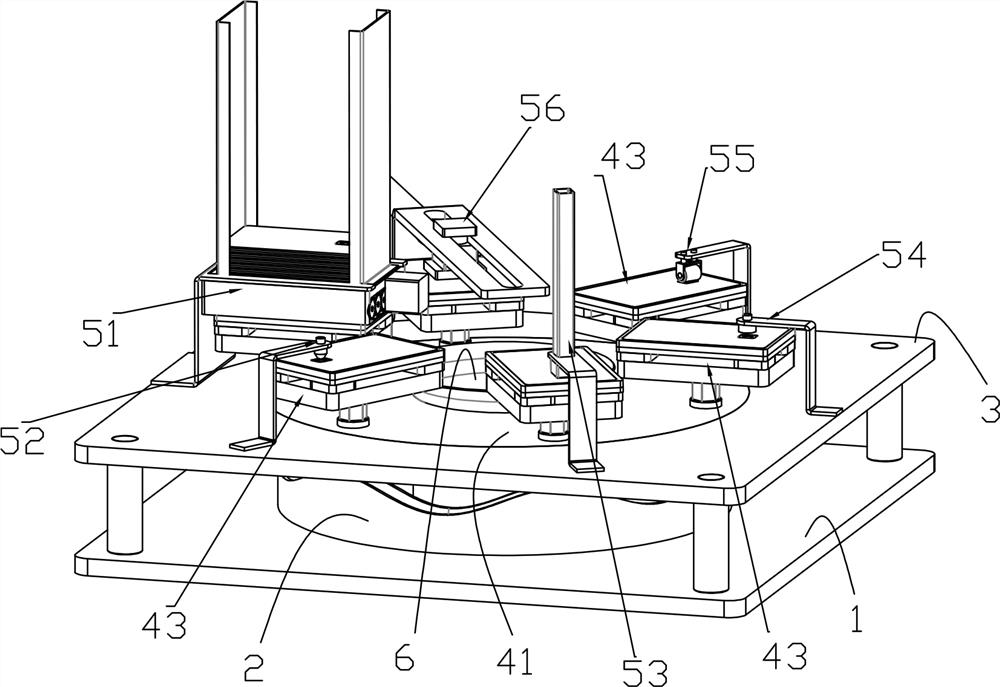

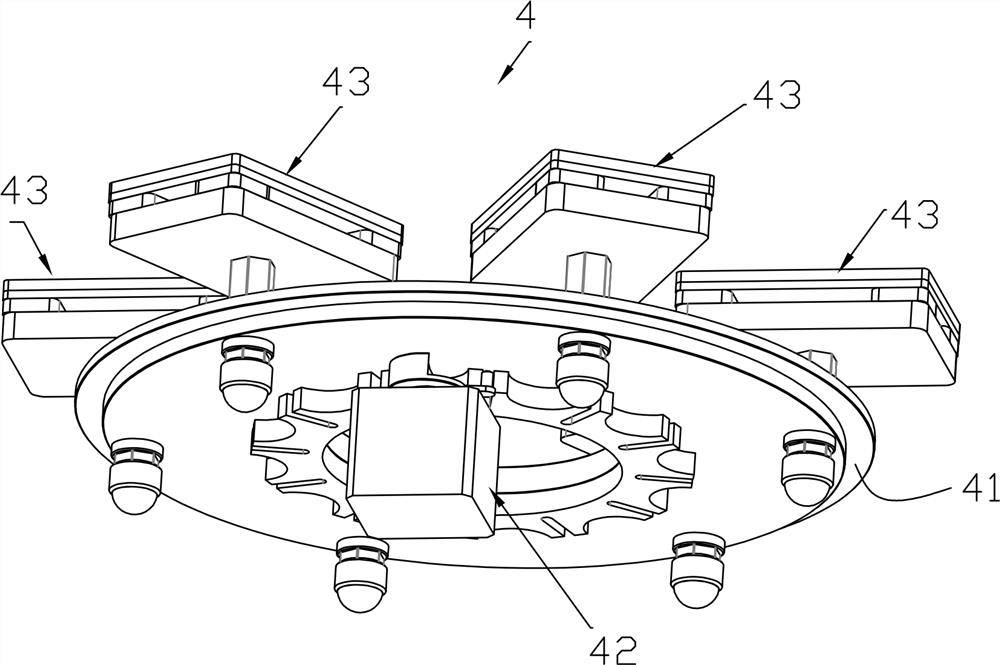

[0032] Such as Figure 1 to Figure 10 As shown, a kind of rotary cycle track-driven IC card packaging robot described in this embodiment includes a base plate 1, a circular tube-shaped lower rail seat 2 arranged on the base plate 1, connected to the base plate 1 by four support columns and has The top plate 3 of the first central hole, the rotating material transfer device 4 arranged in the first central hole of the top plate 3 and the packaging components arranged on the top plate 3;

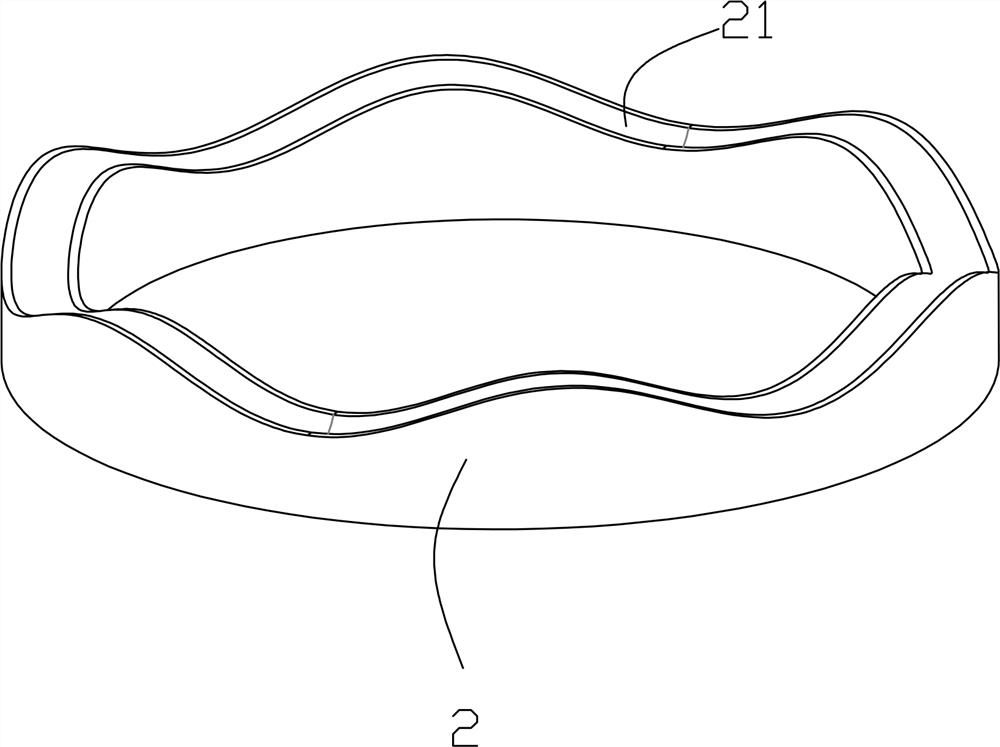

[0033] The upper end surface of the lower track seat 2 is provided with a wave-shaped driving track 21 along the circumference, and the outer diameter of the lower track seat 2 is adapted to the inner diameter of the first central hole of the top plate 3;

[0034] The rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com