Systems and methods for buffer sensing in controlled short circuit welding system

A technology of buffers and control circuits, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as inability to produce high-quality welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

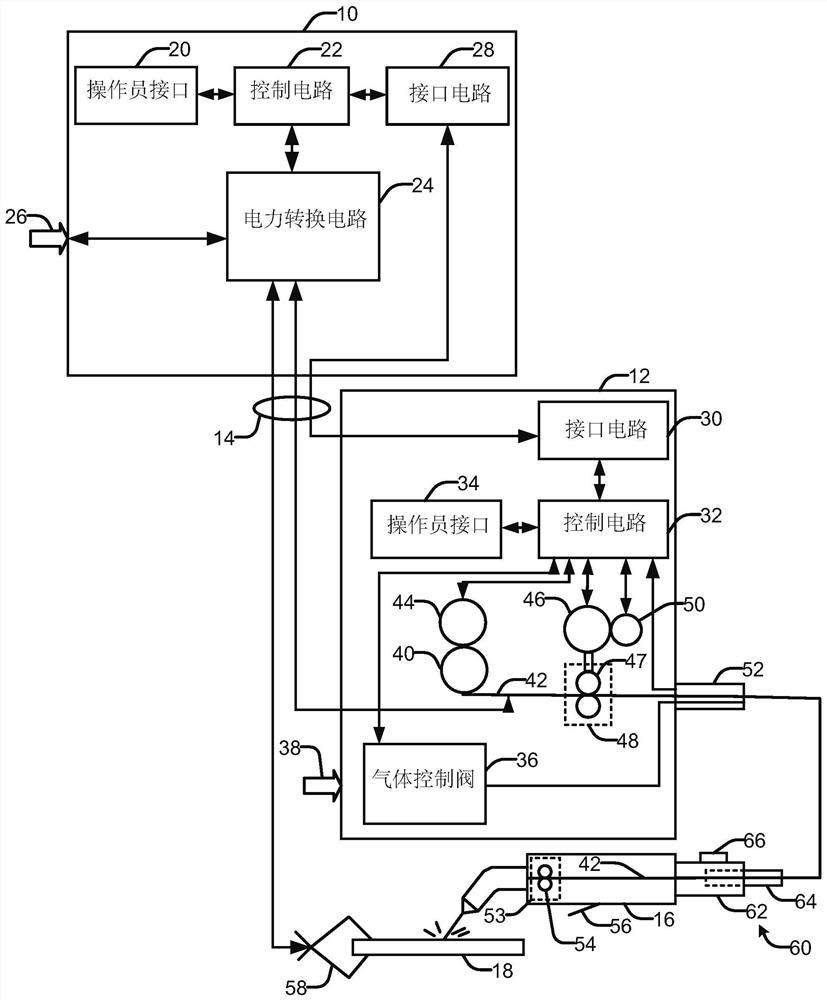

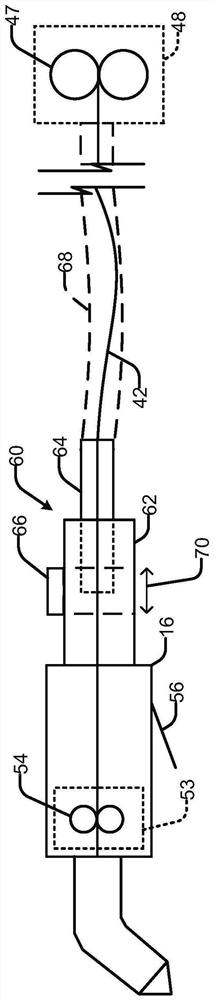

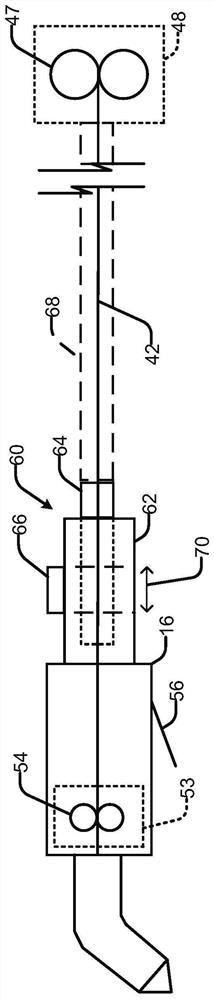

[0025] The present disclosure describes systems and methods for controlling one or more wire feeder motors in response to sensor data during a controlled short circuit welding process. As more fully described with respect to the several figures, the moveable buffer comprising the first portion and the second portion is monitored by sensors to sense changes in the amount of welding wire between the first wire feeder motor and the second wire feeder motor instructions so that wire position and speed can be adjusted according to a control scheme implemented by the control circuit.

[0026] For example, short circuit cycle welding processes operate by alternating between short circuit events and arc events. For example, arcing events can be adjusted to control short circuit clearing to occur. In one example, it is desirable during a MIG welding process that molten droplets from the welding wire enter the weld puddle at relatively low current levels. If the current level is too h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap