Efficient extrusion forming equipment for household cheese

An extrusion molding, household technology, used in applications, cheese substitutes, dairy products, etc., can solve the problems of difficult demoulding, slow cheese molding speed, etc., to achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

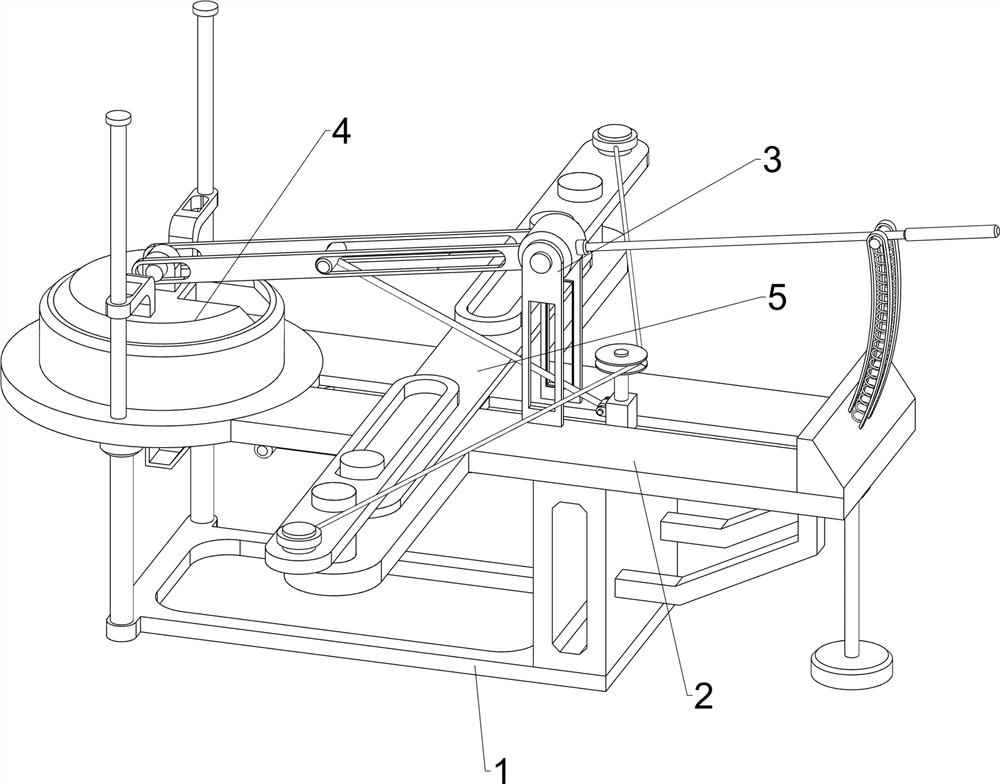

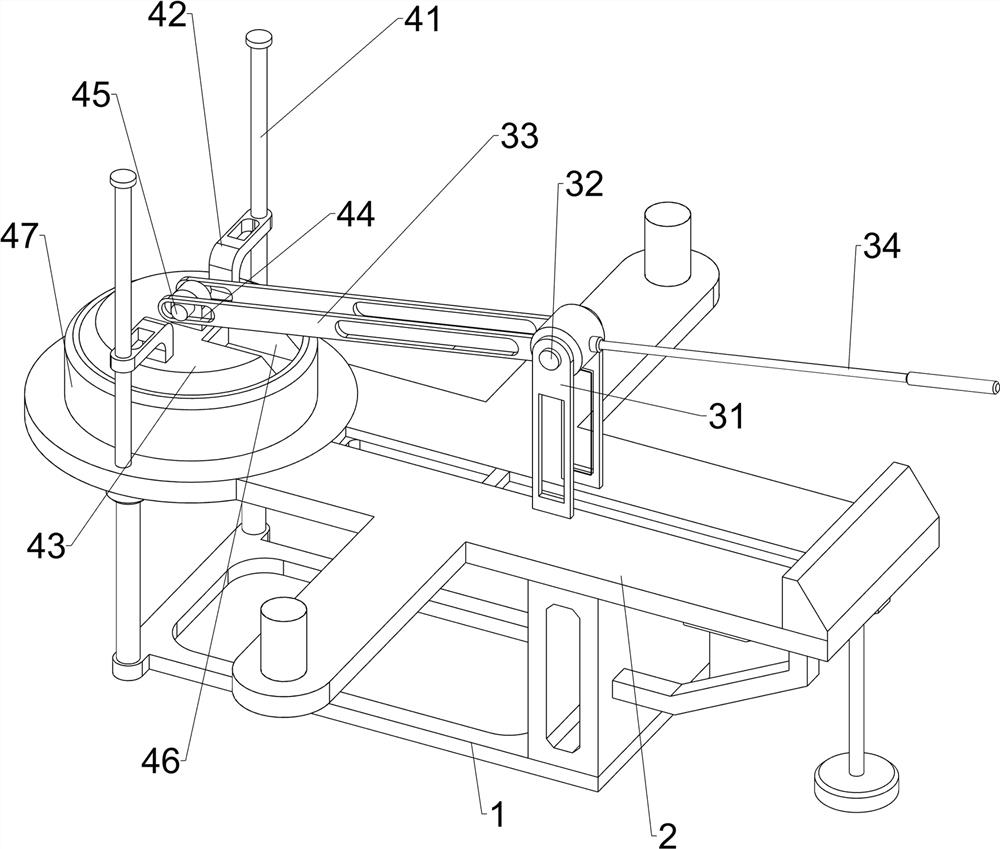

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a high-efficiency extrusion molding equipment for household cheese includes a bottom plate 1, a bracket 2, a driving mechanism 3, an extrusion mechanism 4, and an extrusion mechanism 5. The top of the bottom plate 1 is provided with a bracket 2, and the top of the bracket 2 is provided with a drive Mechanism 3, an extruding mechanism 4 is arranged between the top of the bracket 2 and the driving mechanism 3 , an extruding mechanism 5 is arranged on the top of the bracket 2 , and the extruding mechanism 5 cooperates with the extruding mechanism 4 .

[0027] The driving mechanism 3 includes a bearing seat 31, a rotating shaft 32, a first connecting rod 33 and a handle 34. The top of the support 2 is symmetrically provided with a bearing seat 31, and a rotating shaft 32 is arranged between the bearing seats 31. The left side of the rotating shaft 32 is symmetrically provided with a first A connecting rod 33...

Embodiment 2

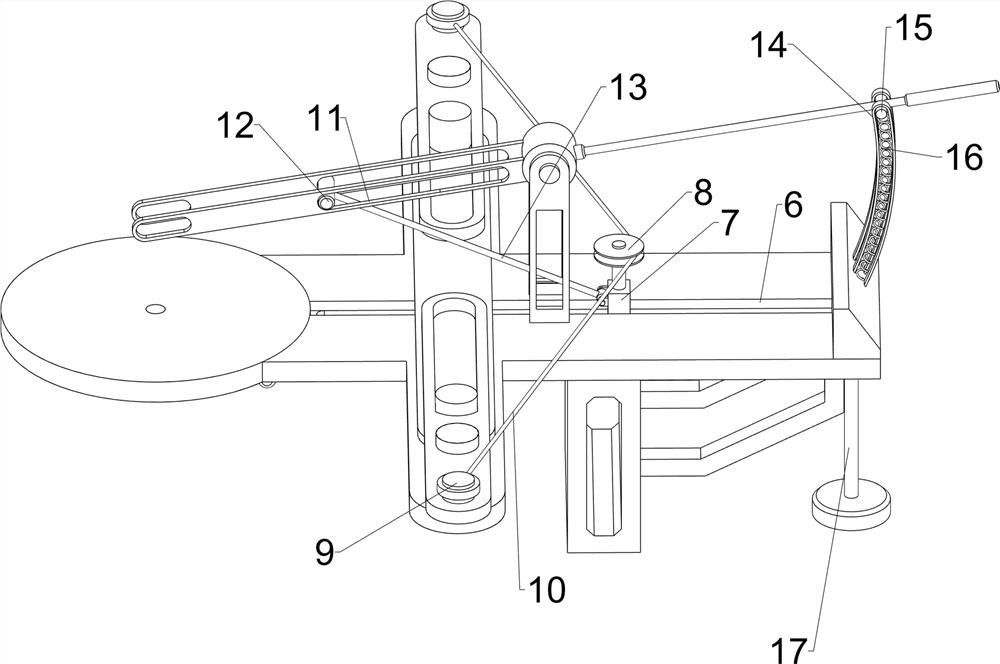

[0032] Such as Figure 5 As shown, a high-efficiency extrusion molding equipment for household cheese also includes a first slider 7, a winding wheel 8, a second fixed block 9 and a pull cord 10, and a third chute 6 is opened on the right side of the top of the bracket 2 , the third chute 6 is provided with a sliding first slider 7, the top of the first slider 7 is rotatably provided with a reel 8, and the top of the two back-shaped groove bars 56 is provided with a second fixed The block 9 is wound with a stay cord 10 on the reel 8, and the two ends of the stay cord 10 are respectively connected with two second fixed blocks 9.

[0033] When the staff needs to perform cheese extrusion molding, the staff pours the concentrated milk into the placement bucket 47, and after the pressing block 43 squeezes the cheese, the staff holds the handle 34 to drive the first connecting rod 33 around the rotating shaft 32 Rotate, and then drive the pressing block 43 to move upwards in the plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com