Measurement system and measurement method

A measurement system and measurement die technology, applied in the field of robotics, can solve problems such as affecting accuracy, incapable of diversifying assembly tasks, and narrow space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

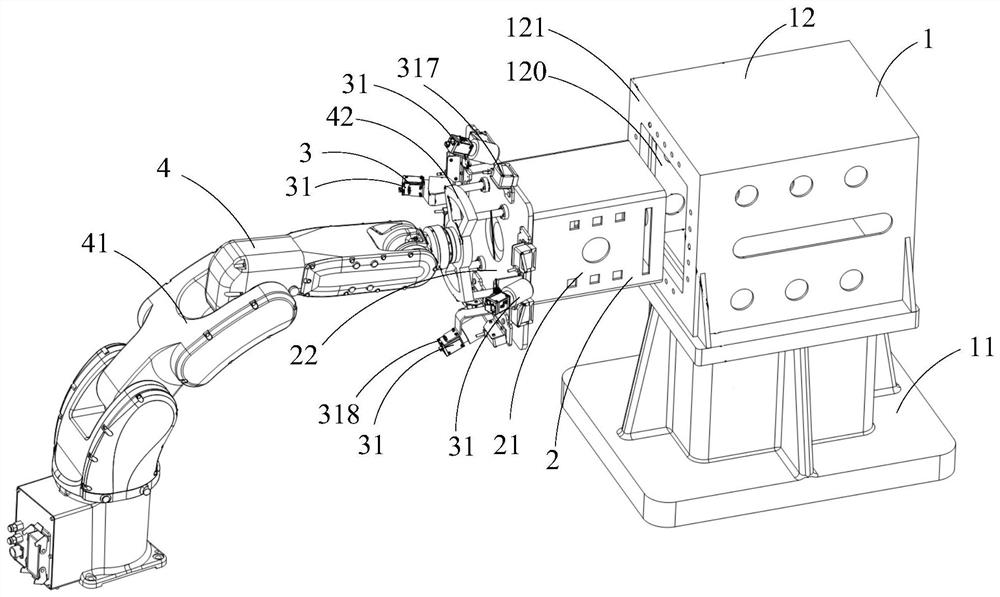

[0027] Such as figure 1 as shown, figure 1 A schematic structural view of the first component 1 and the second component 2 that need to be assembled together in this embodiment is shown.

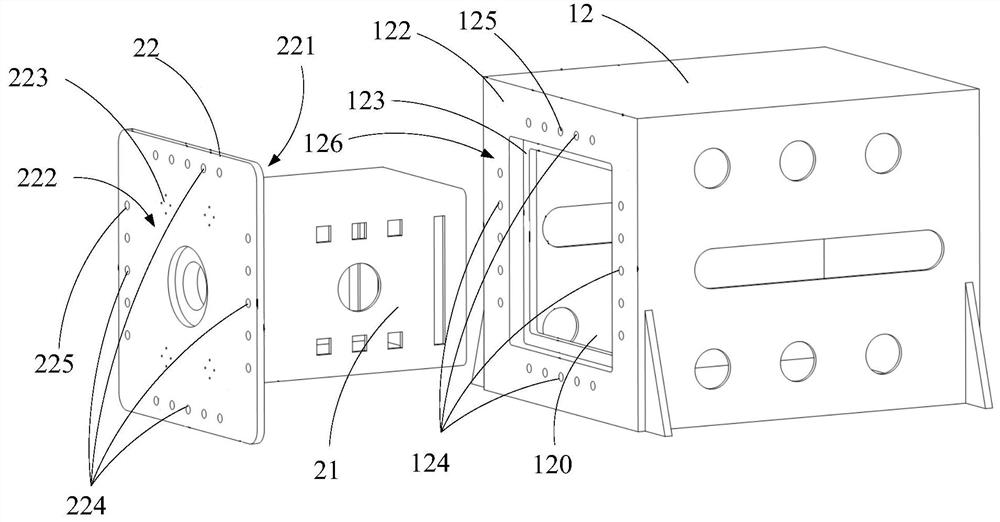

[0028] The first part 1 comprises a base 11 and a cabin 12 . The cockpit 12 is fixedly installed above the base 11 . The base 11 sits on the ground. The base 11 supports the cabin 12 . The cabin 12 has a substantially box shape. The cabin 12 includes a first mounting plate 121 . The first assembly plate 121 is a side plate of the cabin 12 . The first assembly plate 121 has a substantially frame shape, such as a square frame shape.

[0029] Such as figure 2 As shown, there is a window 120 in the middle of the first assembly plate 121 , and the window 120 may be a square window 120 . An inner edge of the first assembly plate 121 is recessed inwardly to form a concave step 123 . The concave step 123 is disposed around the window 120 . That is, the first assembly plate 121 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com