Sub-pixel-level PCB board defect reference point detection method

A PCB board and sub-pixel level technology, which is applied in the field of SMT high-speed and high-precision automatic placement machines, can solve the problem that the accuracy does not reach the sub-pixel level, and achieve the effects of enhancing accuracy, improving accuracy, and reducing mis-segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

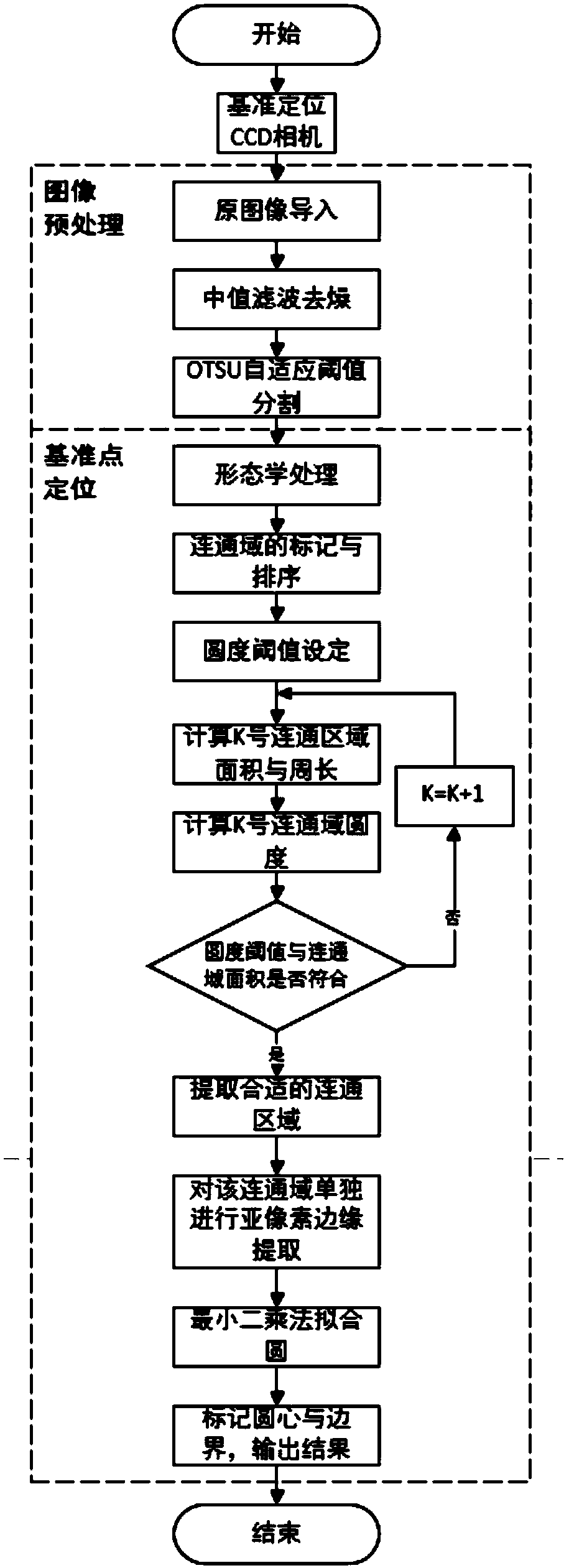

[0070] Such as figure 1 As shown, a sub-pixel level PCB board defect reference point detection method according to the present invention specifically includes the following steps:

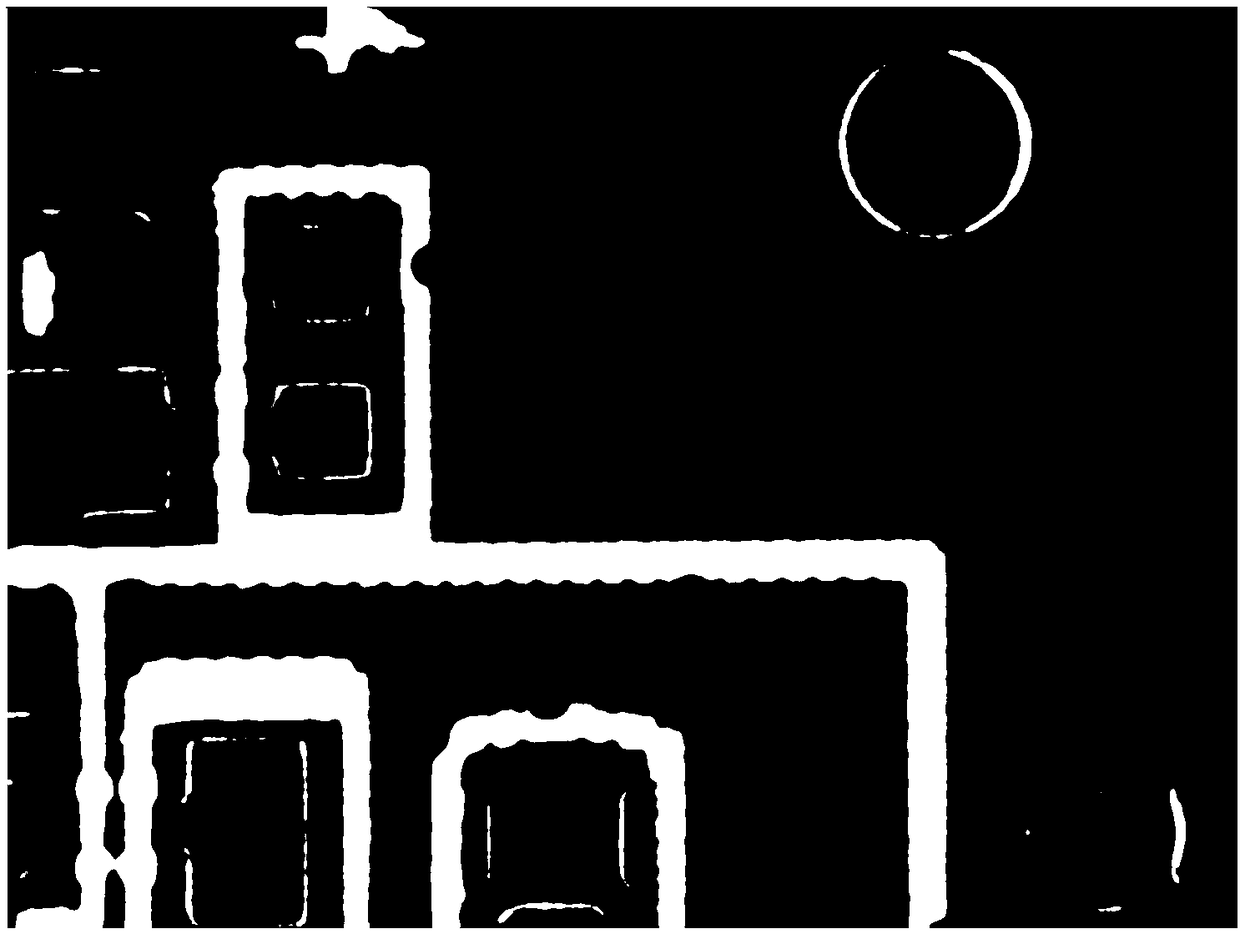

[0071] S1. Acquisition of the original image: read in an original image 1 of the PCB board with a size of 480×640 through the reference positioning CCD camera, such as figure 2 shown;

[0072] S2, preprocessing the original image of the PCB board, including the following steps:

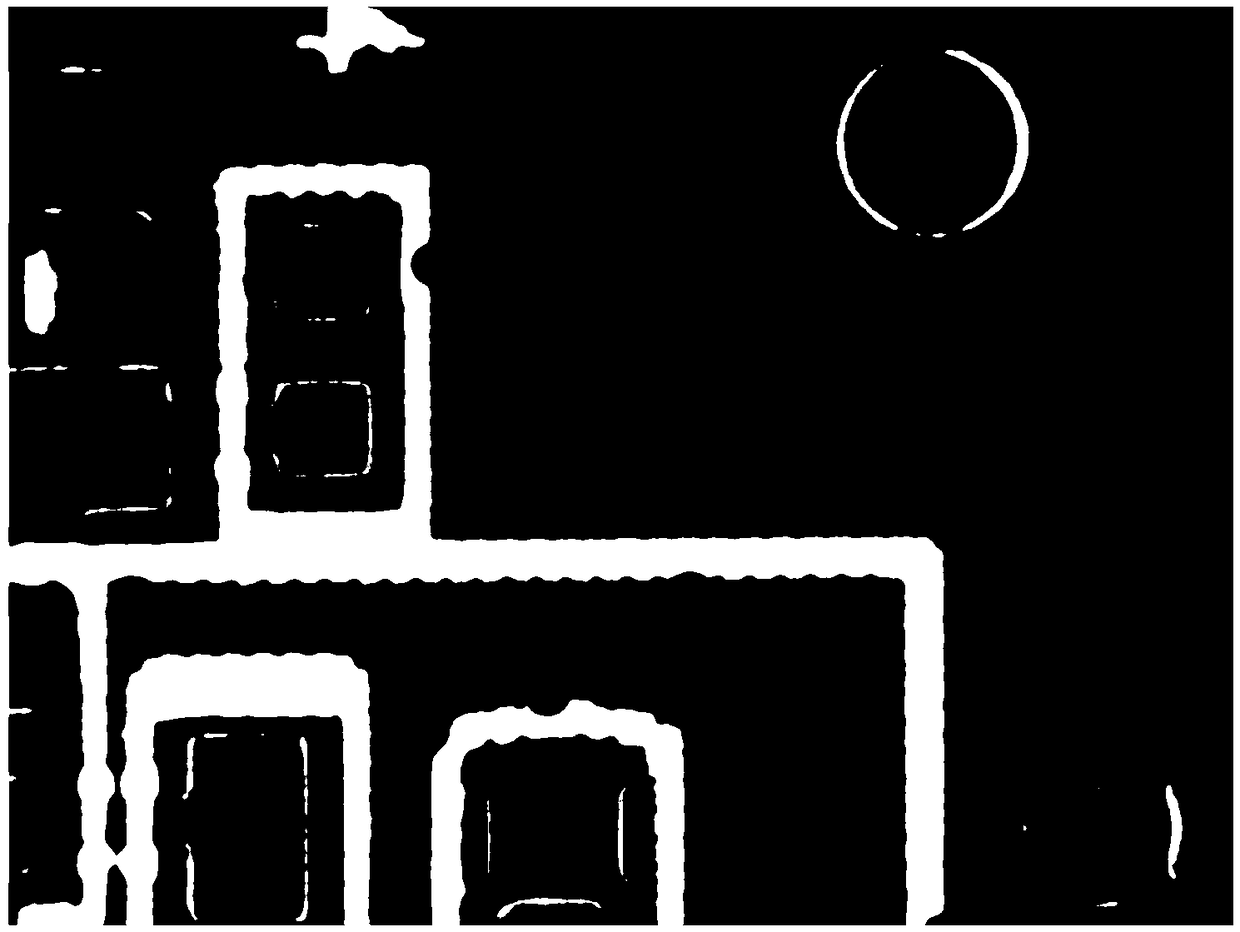

[0073] S2.1. Adaptive median filter denoising: perform median filter denoising on the target image to obtain denoised image 2; image 3 As shown, the specific steps are:

[0074] order z min = S xy The minimum gray value in z max = S xy The maximum gray value in z med = S xy The median gray value in z xy =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com