Train pipe leakage searching method

A technology for train pipes and trains, applied in the direction of detecting the appearance of fluid at the leak point, testing of machine/structural components, instruments, etc., can solve the problem of long-term occupancy, the inability to quickly distinguish the train pipe air pipeline system and the brake cabinet Train piping system, leak finding and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

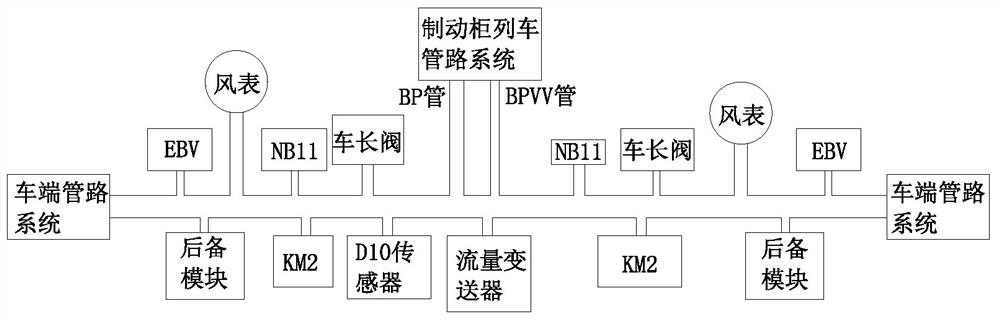

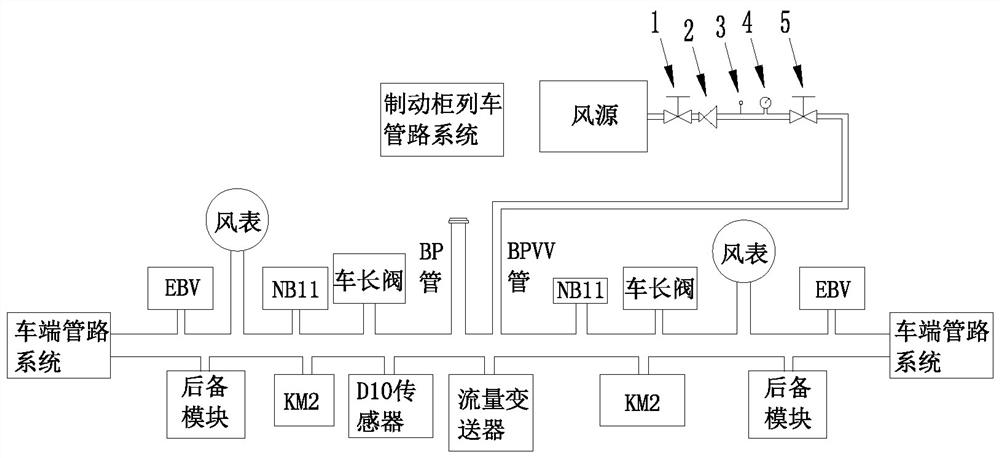

[0023] Such as figure 1 , 2 As shown, the train pipeline system includes the train pipeline air pipeline system and the brake cabinet train pipeline system, the train pipe air pipeline system is connected to the brake cabinet train pipeline system through the BP pipe and the BPVV pipe

[0024] In the present invention, the train pipeline system is inflated to detect leakage points by utilizing inflatable tooling, the inflatable tooling includes an inflatable pipeline, a pressure regulating valve 2 arranged on the inflatable pipeline, an air gauge 4, a test port 3 for testing air pressure, The first cut-off plug door 1 arranged at the input end of the inflation pipeline and the second cut-off plug door 5 arranged at the output end of the inflation pipeline, the input end of the inflatable tooling is provided with a quick connector, the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com