Sealed alternating-current metal switch equipment mechanism chamber and alternating-current metal switch equipment

A technology for switchgear and mechanism room, applied in the field of switchgear, can solve the problems of installation of operating mechanism and sealed box, inconvenient operation, maintenance, inconvenient replacement of parts, increase in overall volume, etc., so as to reduce the cost increase and structure. Simple, resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application will be further introduced below in conjunction with the embodiments.

[0028] In order to more clearly describe the embodiments of the present invention or the technical solutions in the prior art, in the following description, different "an embodiment" or "an embodiment" do not necessarily refer to the same embodiment. Different embodiments can be replaced or combined, and those skilled in the art can obtain other implementations based on these embodiments without any creative effort.

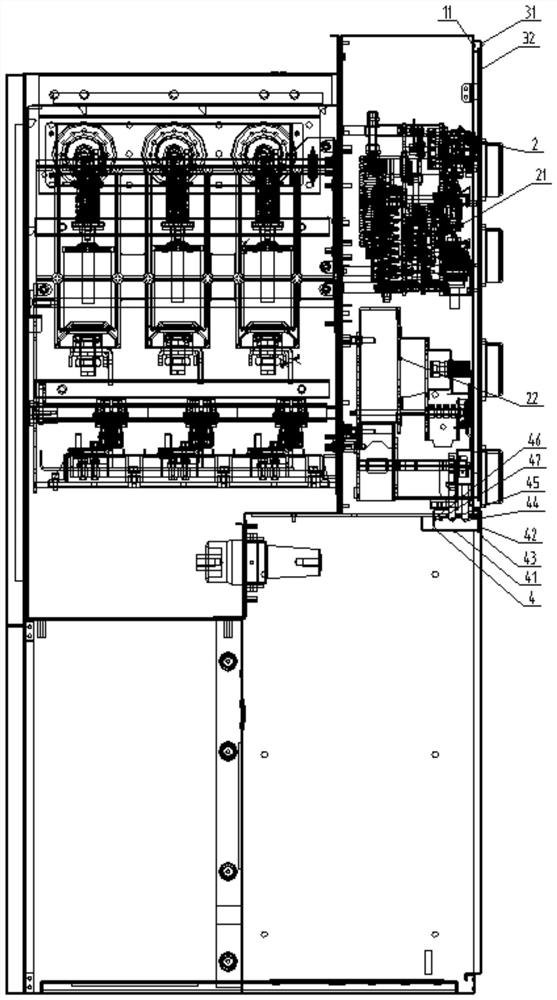

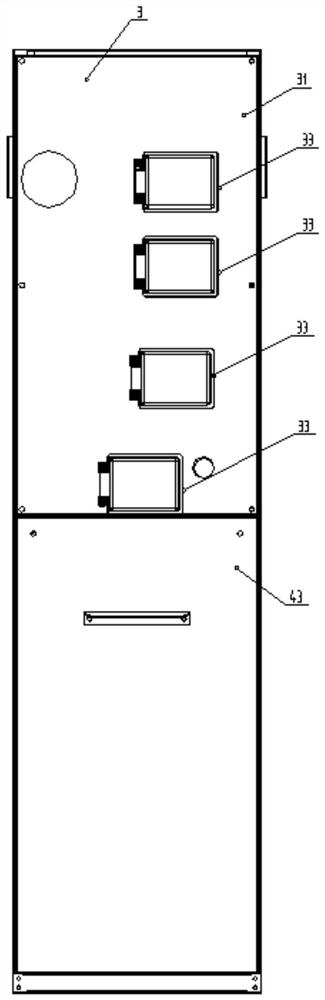

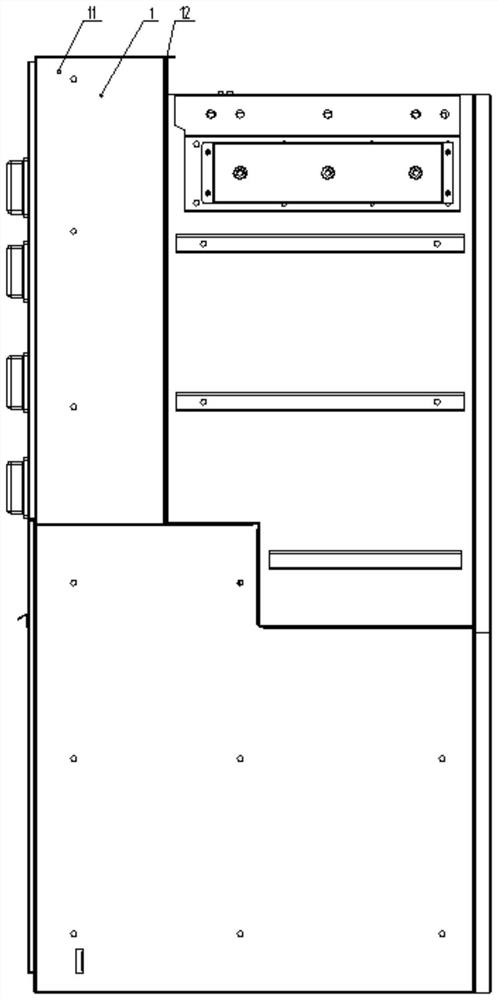

[0029] combined with Figure 1-4 , a sealed AC metal switchgear mechanism room, the sealed AC metal-enclosed switchgear includes a switch room, a mechanism room and a cable room, and the mechanism room includes a mechanism room body unit 11, a mechanism room panel 3 and an operating mechanism 2;

[0030] The rear part of the mechanism room body unit 1 is fixed on the switch room, and the space between the mechanism room body unit 1 and the switch room is sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com