Screening device for preparing recycled aggregate concrete from construction waste

A technology for regenerating aggregates and construction waste, which is used in sieves, solid separation, and separation of solids from solids by air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

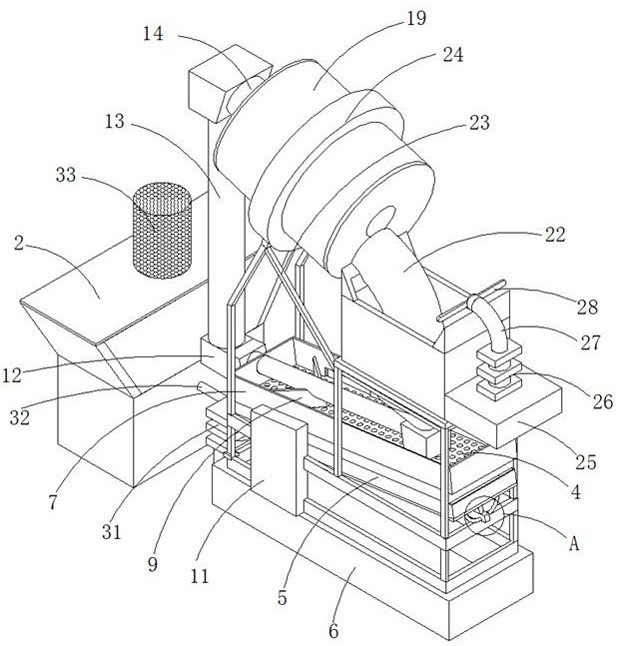

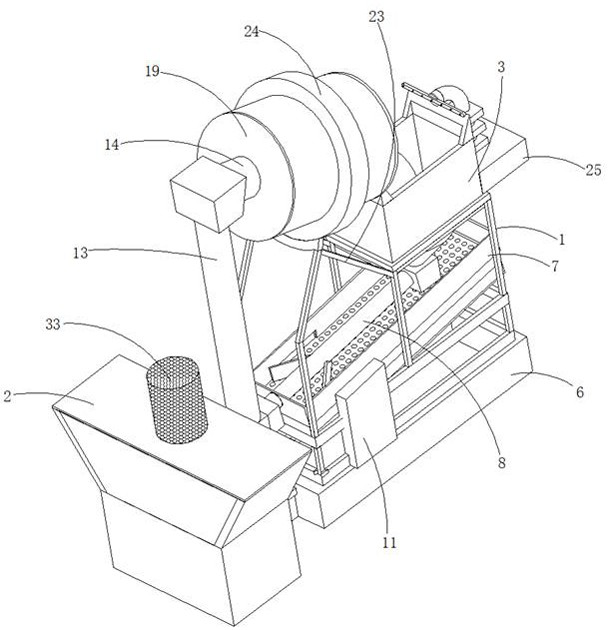

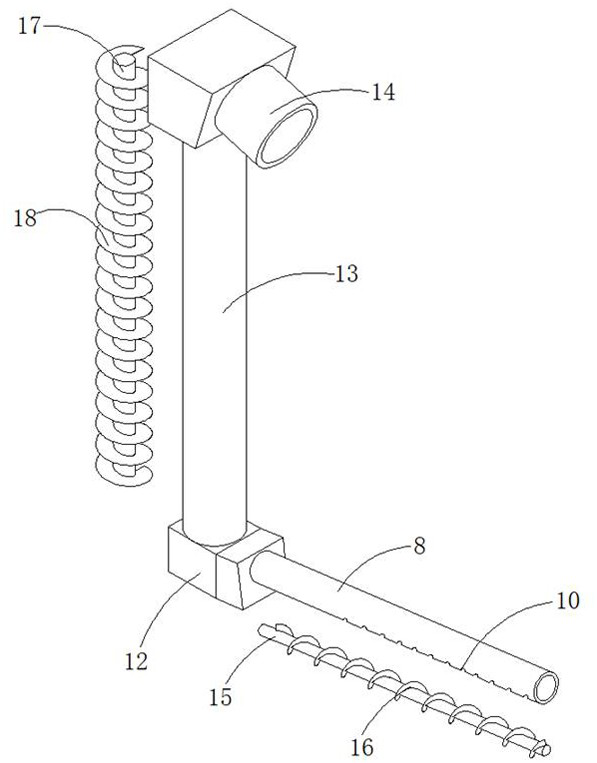

[0030] refer to Figure 1-5 , a screening device for preparing recycled aggregate concrete from construction waste, comprising a frame 1 and a stacking box 2, the frame 1 is arranged opposite to the stacking box 2, and the frame 1 is connected with a feeding box 3 in sequence along the vertical direction , vibrating screen 4, the first collection box 5 and the second collection box 6, the outer edge of the vibrating screen 4 is provided with a coaming 7, and the bottom outlet of the feeding box 3 is equipped with a vibrating screen 4 Above the first feeding cylinder 8, the first feeding cylinder 8 is equipped with a material progressive assembly, and the first feeding cylinder 8 is arranged in parallel with the vibrating screen 4, and the top of the vibrating screen 4 is fixed with a V-shaped interceptor Plate 9, the bottom of the first feeding tube 8 between the discharge port of the feeding box 3 and the V-shaped intercepting plate 9 is provided with a feeding hole 10, and t...

Embodiment 2

[0041] refer to Figure 1-5 , a screening device for preparing recycled aggregate concrete from construction waste, comprising a frame 1 and a stacking box 2, the frame 1 is arranged opposite to the stacking box 2, and the frame 1 is connected with a feeding box 3 in sequence along the vertical direction , vibrating screen 4, the first collection box 5 and the second collection box 6, the outer edge of the vibrating screen 4 is provided with a coaming 7, and the bottom outlet of the feeding box 3 is equipped with a vibrating screen 4 Above the first feeding cylinder 8, the first feeding cylinder 8 is equipped with a material progressive assembly, and the first feeding cylinder 8 is arranged in parallel with the vibrating screen 4, and the top of the vibrating screen 4 is fixed with a V-shaped interceptor Plate 9, the bottom of the first feeding tube 8 between the discharge port of the feeding box 3 and the V-shaped intercepting plate 9 is provided with a feeding hole 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com