Equipment for sorting metal in garbage

A garbage and metal technology, applied in the field of equipment for sorting metals in garbage, can solve the problems of inability to guarantee the sorting effect and low sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

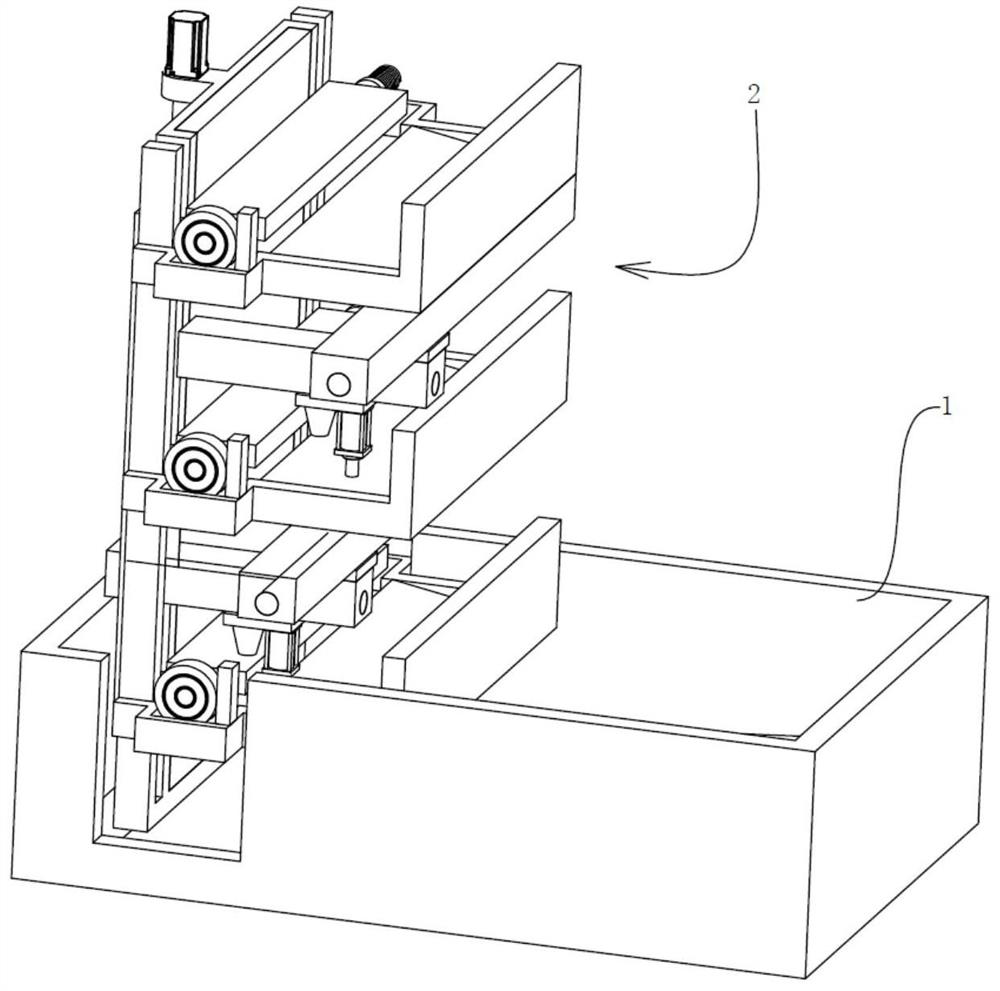

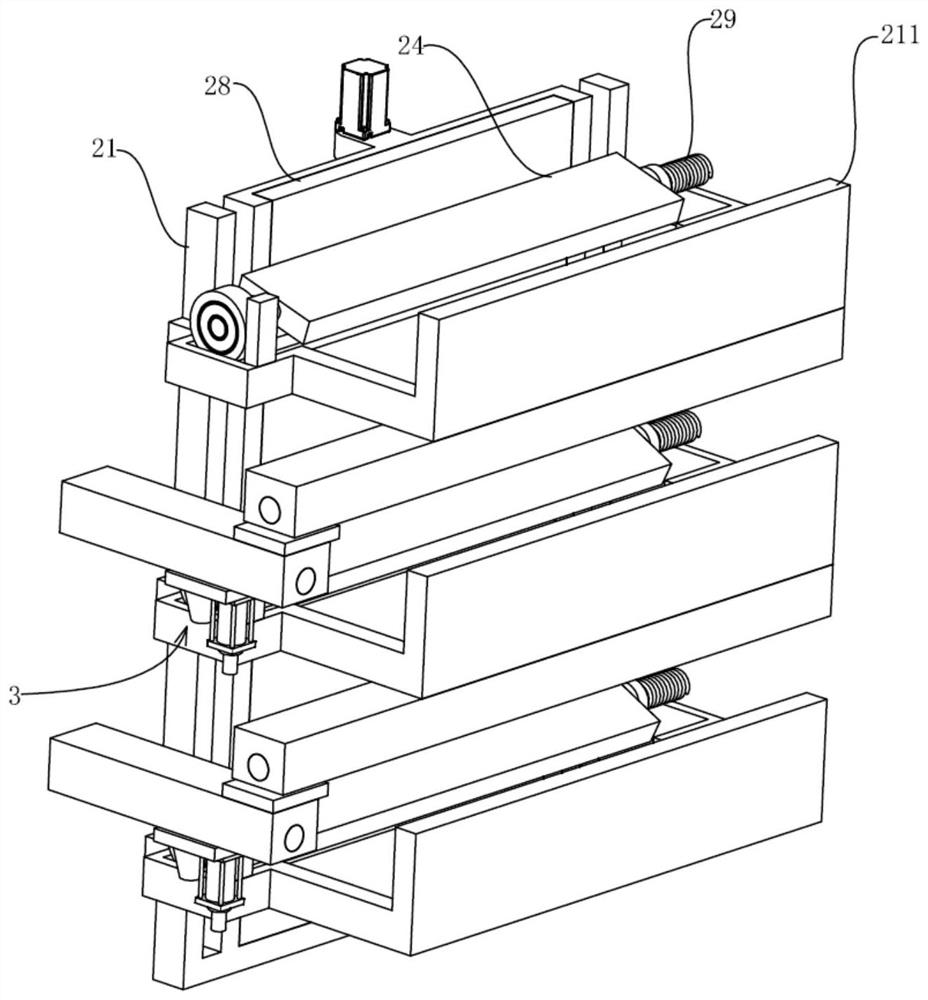

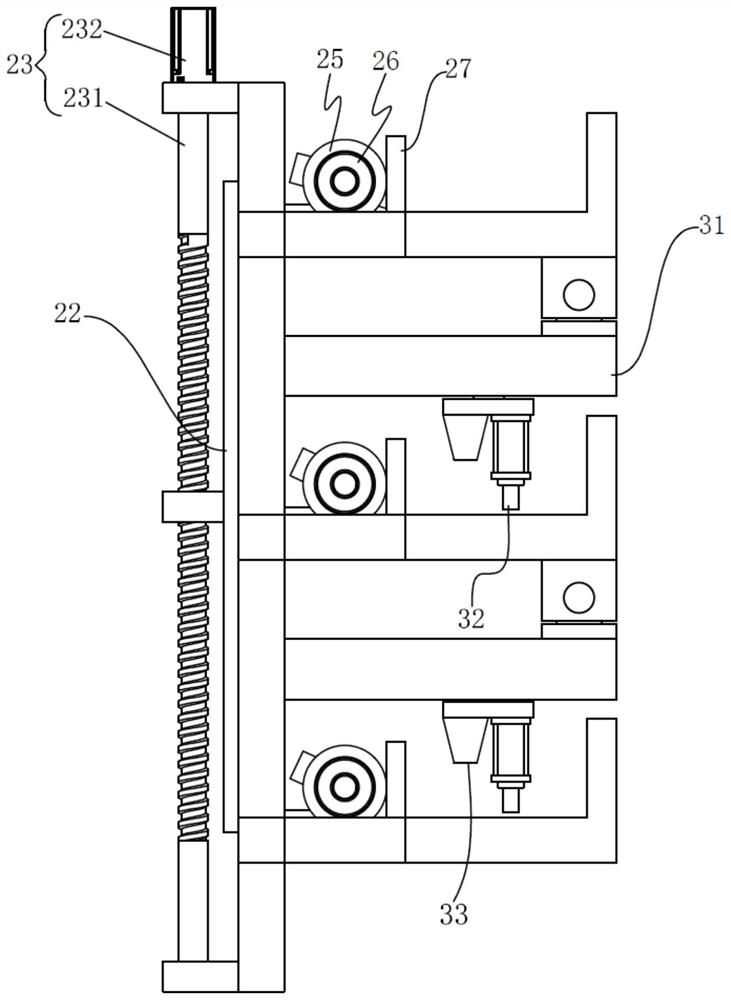

[0023] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0024] A device for sorting metals in garbage, including a storage box 1, a conveying separation component 2 and an optical selection component 3, wherein:

[0025] The inner bottom of the storage box 1 is inclined, and the conveying and separating assembly 2 includes a vertical support 21, an I-shaped frame 22, a linear drive mechanism 23, a feeding plate 24, a friction wheel 25, a one-way bearing 26, a friction plate 27, and a magnet type Suction plate 28 and torsion spring 29, vertical support 21 are arranged in storage box 1, and vertical support 21 is provided with at least two collection boxes 211, and wherein the inner bottom plate of collection box 211 is for inclined setting, and inclination direction is away from vertical In the direction of the side wall of the straight support 21, the I-shaped frame 22 is movably installed in the vertical guide groove in the vertical support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com