Hydraulic lifting trolley for loading, unloading and transporting rolling mill bearings

A hydraulic lifting and bearing technology, which is applied to motor vehicles, multi-axis trolleys, transportation and packaging, etc., can solve the problems of high labor intensity, time-consuming and labor-intensive, large diameter, etc., to reduce labor intensity, reduce safety risks, change loading and unloading Effect of Mode and Mode of Shipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

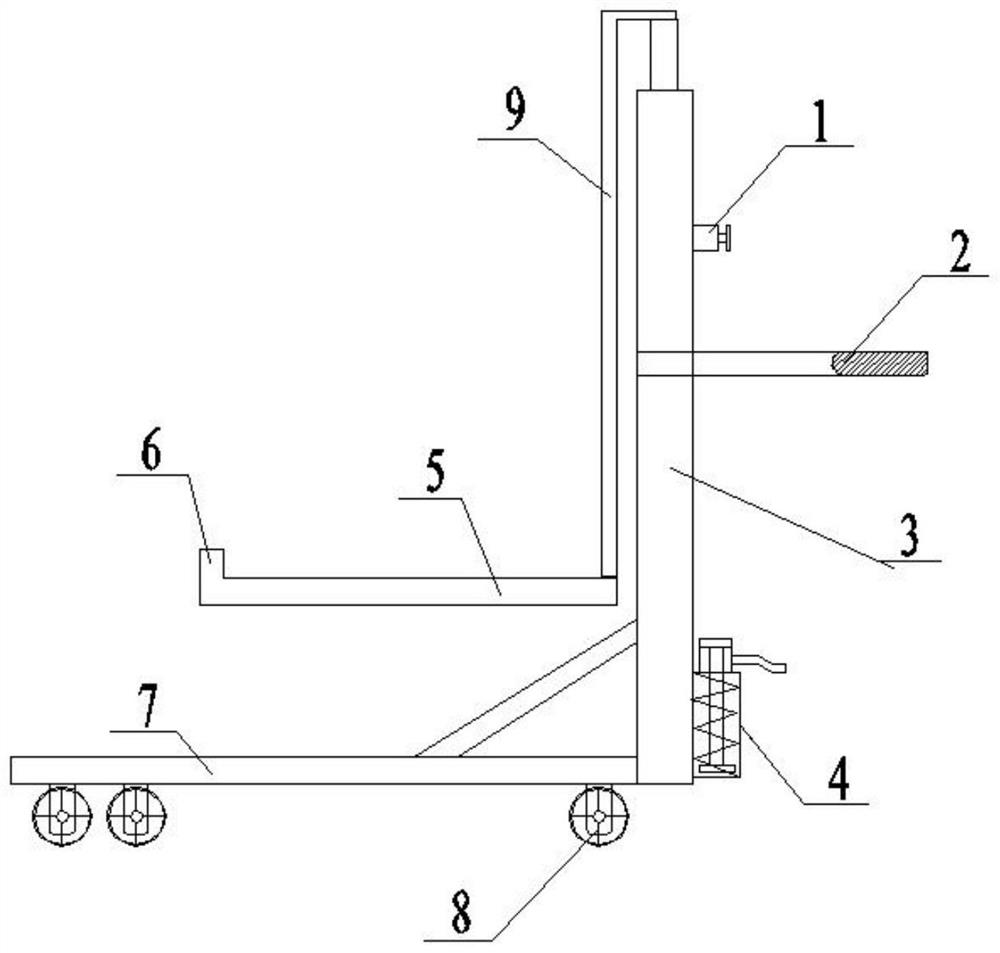

[0016] The embodiment of the invention discloses a hydraulic lifting trolley used for loading and unloading transportation of rolling mill bearings, such as figure 1 As shown, including vehicle frame 7, vehicle frame 7 is frame structure, and its rear end is equipped with vertical hydraulic cylinder 3, and the vertical of hydraulic cylinder 3 is upward; Rod 5, the bearing support rod 5 faces the front end of the vehicle frame 7, the bearing support rod 5 is used to pass through the inner ring of the bearing; Block the bearing that is sleeved on the bearing support rod 5 to prevent it from slipping; the bottom of the vehicle frame 7 is provided with wheels.

[0017] In the embodiment of the present invention, the bearing can be realized by putting the bearing on the bearing support rod, preventing it from slipping through the limit convex edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com