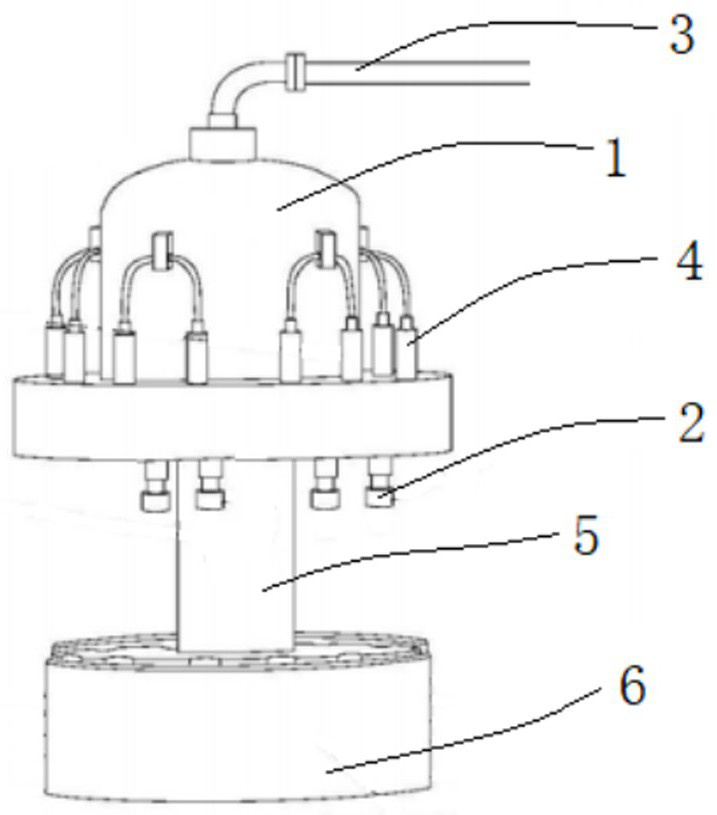

Rotary type canning equipment

A rotating and canning technology, which is applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problems of difficult canning, easy cavity formation, beverage spillage, etc., to avoid unevenness and reduce the amount of foam , the effect of reducing the amount of generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

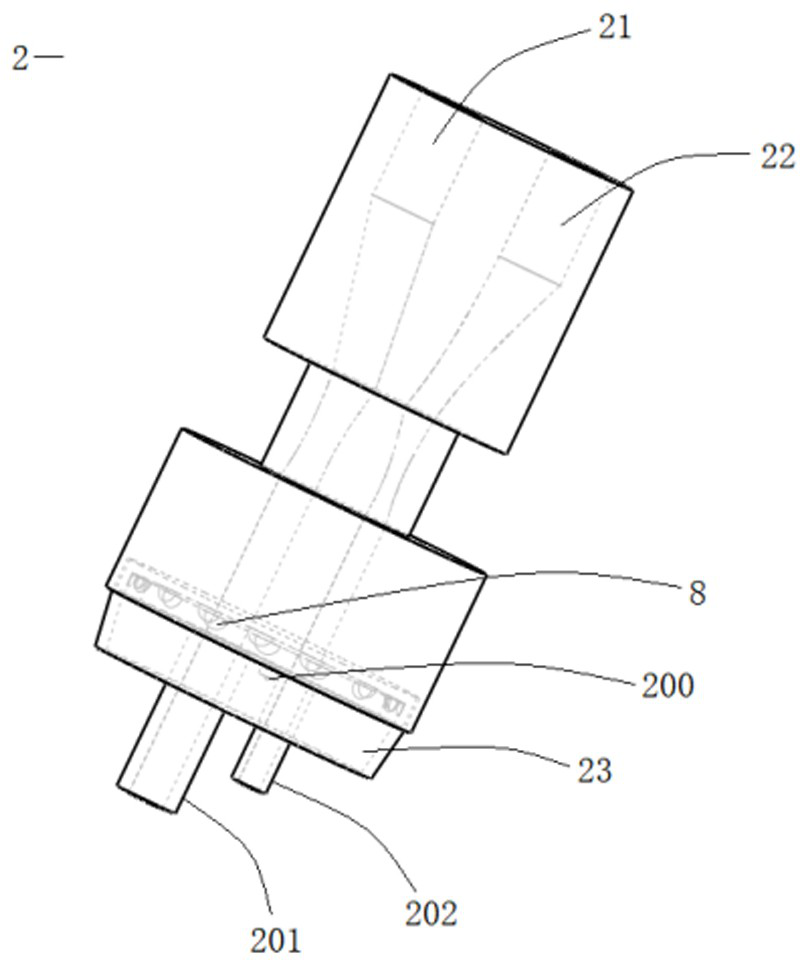

Method used

Image

Examples

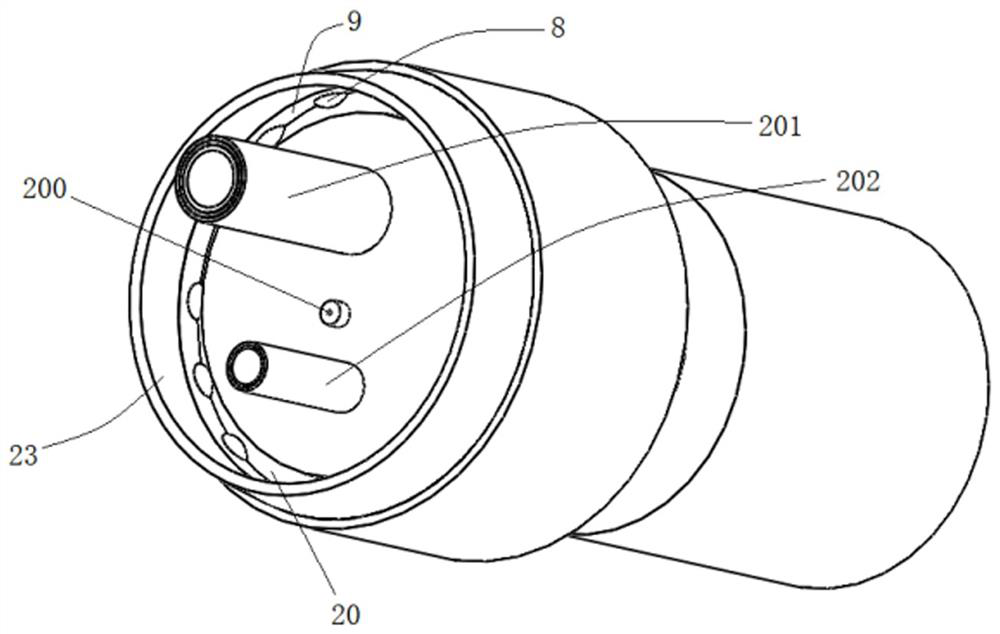

Embodiment 2

[0043] The main difference between the present embodiment and the first embodiment is that the liquid outlet faces the side wall of the beverage bottle body and is arranged obliquely downward. The liquid outlet is facing the side wall of the beverage bottle body, and is set inclined downward, so that the beverage flows from the inner wall of the bottle body to the bottom of the bottle, preventing the liquid from falling vertically from the liquid outlet, thereby reducing the generation of foam to a certain extent .

[0044] The technical solution of the rotary canning equipment disclosed in this embodiment is the same as that in the first embodiment, please refer to the description in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com