High comfort prefabricated cement concrete pavement repair structure, construction method and pavement structure overturning device

A cement concrete and pavement restoration technology, which is applied to road restoration, on-site coagulation pavement, roads, etc., can solve problems such as difficult demolition, poor pavement comfort, structural rutting, push hugging, etc., to shorten the construction period and facilitate Effect of installation and improvement of driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

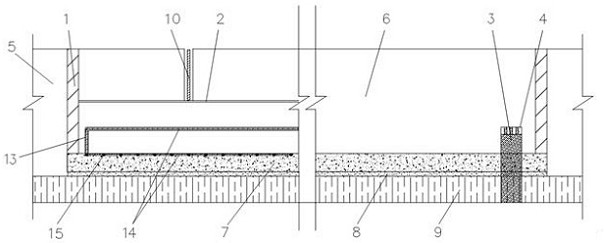

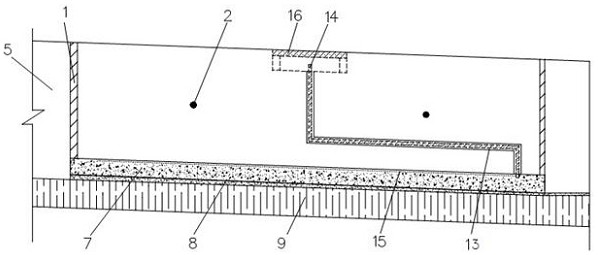

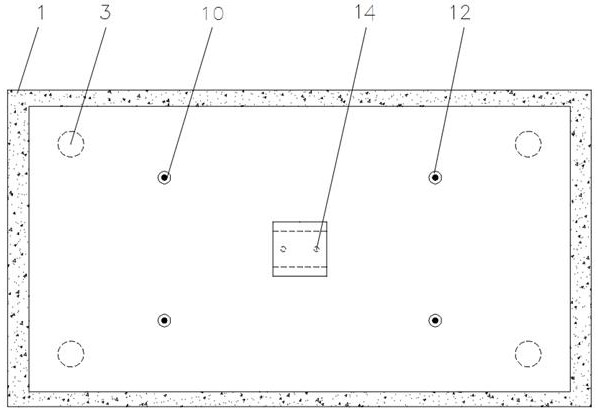

[0045] Such as Figure 1~Figure 5 As shown, a high-comfort assembled cement concrete pavement repair structure includes: asphalt 1, prestressed steel bars 2, prefabricated limit piles 3, clamping teeth 4, original asphalt concrete pavement 5, assembled cement concrete slab 6, asphalt Concrete cushion 7, waterproof layer 8, pavement base 9, hoisting screws 10, reserved holes 12, conduits 13, wires 14, heating wires 15, metal cover plates 16, wire joint boxes 17.

[0046] On the pavement base 9, four prefabricated limit piles 3 are set at the four corners corresponding to the position of the assembled cement concrete slab 6, and the tops of the prefabricated limit piles 3 are provided with locking teeth; the prefabricated limit piles 3 pass through the waterproof layer 8. Asphalt concrete cushion layer 7, the teeth provided at the top of the prefabricated limit pile 3 are embedded into the corresponding teeth 4 provided in the assembled cement concrete slab 6, which is used to i...

Embodiment 2

[0068] Such as Image 6 with Figure 7 As shown, another assembled asphalt cement concrete pavement structure, including: asphalt 1, prestressed steel bars 2, prefabricated limit piles 3, clamping teeth 4, original asphalt concrete pavement 5, assembled cement concrete slab 6, asphalt concrete pad Layer 7, waterproof layer 8, pavement base 9, lifting screw 10, reserved hole 12, conduit 13, wire 14, heating wire 15, metal cover plate 16, wire joint box 17, asphalt concrete surface layer 26.

[0069] Different from Example 1, the prefabricated cement concrete slab 6 of this example is a prefabricated upper and lower parts made of different materials. Be the ordinary concrete layer that thickness is 15cm, spray concrete retarder 27 on the surface of the ordinary concrete layer of top, then pave asphalt concrete surface course 26 on the ordinary concrete layer top that sprayed concrete retarder 27 again.

[0070] The construction method of the above-mentioned prefabricated cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com