CO2 and reservoir fluid replacement rule experimental method after dry fracturing soaking

An experimental method and well-holding technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of poor crude oil development effect, weak support, and poor flowback efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A dry fracturing CO2 2 The experimental method of the law of replacement with the reservoir fluid comprises the following steps

[0036] Step 1: Select the plunger core sample in the target area, and manually press it into cracks and install it into the CT holder;

[0037] Step 2: saturate the plunger core sample treated in step 1 with formation water, and use the formation water in the fractured core to displace the formation water to establish irreducible water saturation;

[0038] Step 3: For the plunger core sample saturated formation crude oil processed in step 2, measure the volume V of the original saturated crude oil under the experimental temperature and pressure conditions 0 ;

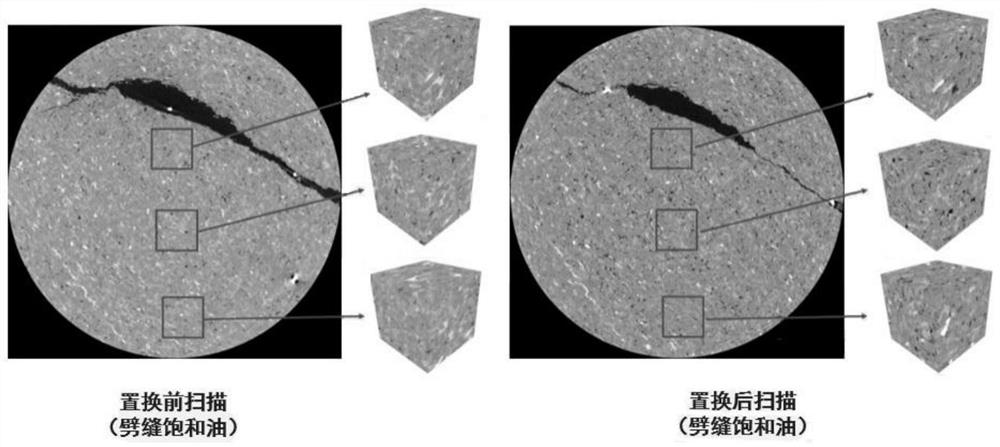

[0039] Step 4: Obtain the initial pore structure characteristics and fluid distribution characteristics of the plunger core sample processed in step 3 by CT scanning;

[0040] Step 5: Inject CO at preset pressure 2 Afterwards, CT scanning is performed, and at the same time, the wel...

Embodiment 2

[0048] A dry fracturing CO2 2 The difference from the first embodiment is that the experimental method of reservoir fluid replacement law is that in the second step, the method of saturating the plunger core sample treated in the first step with formation water is evacuated and pressurized.

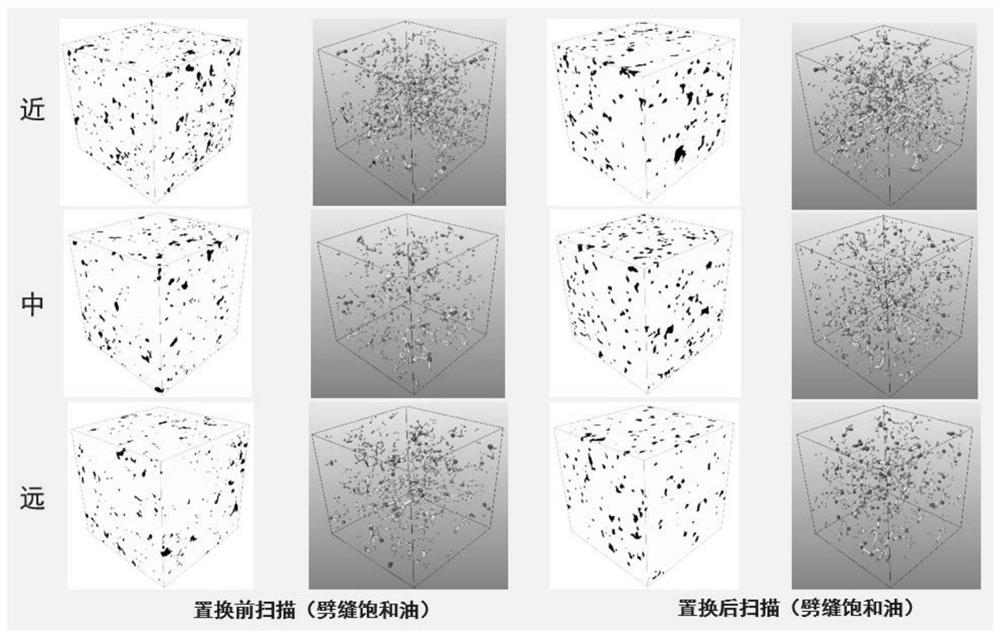

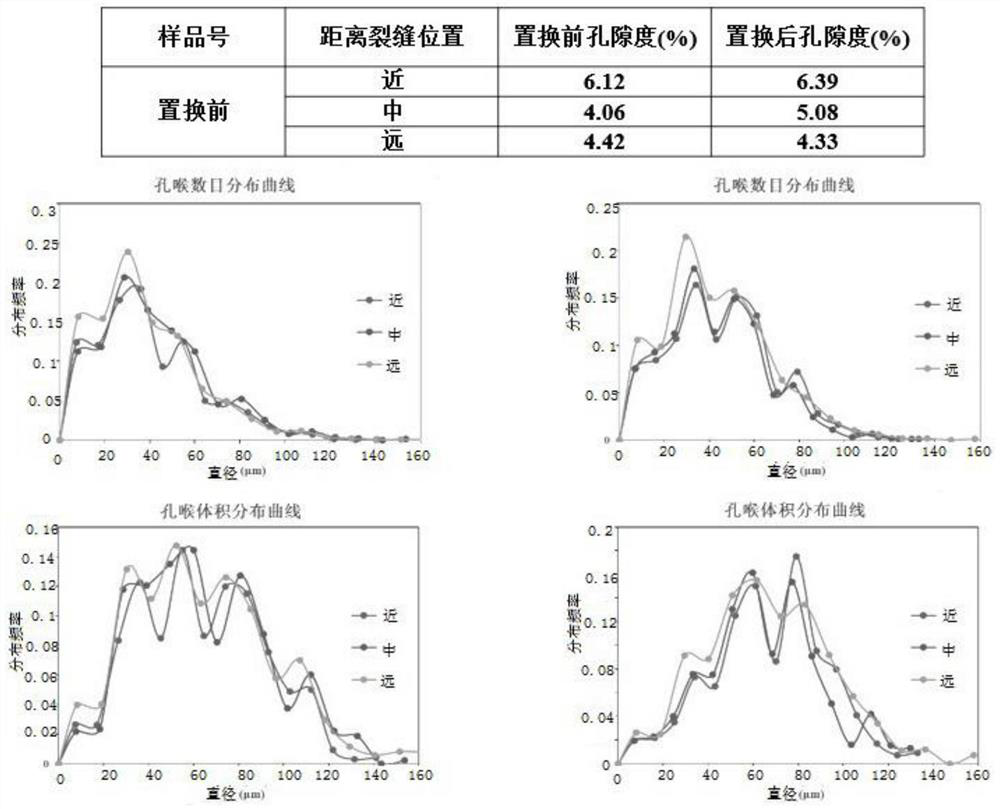

[0049] Further, the initial pore structure characteristics in Step 4 and Step 7 include pore size distribution and throat size distribution; fluid distribution characteristics include oil, gas, and water saturation in the pores.

[0050] Further, the setting of different scanning times in step 5 is set at equal intervals within the preset soaking time.

[0051] Further, the CO injected in the step five 2 99.999% pure.

[0052] Further, the calculation of replacement efficiency in step six of the step is calculated using the following formula to obtain

[0053]

[0054] Among them: E D is the replacement efficiency;

[0055] B 0 is the formation crude oil volume factor;

[0056] V ...

Embodiment 3

[0063] refer to Figure 1-Figure 3 As shown, a dry fracturing CO 2 Experimental method of replacement law with reservoir fluid,

[0064] Step 1: Select a plunger core sample in a target area, and manually press it into cracks and install it into the CT holder;

[0065] Step 2: saturate the plunger core sample treated in step 1 with formation water, and use the formation water in the fractured core to displace the formation water to establish irreducible water saturation;

[0066] Step 3: For the plunger core sample saturated formation crude oil processed in step 2, measure the volume V of the original saturated crude oil under the experimental temperature and pressure conditions 0 , V 0 =1.216mL;

[0067] Step 4: Obtain the initial pore structure characteristics and fluid distribution characteristics of the plunger core sample processed in step 3 through CT scanning; the pore throat size distribution is obtained as 0-158 μm, mainly distributed between 20-100 μm, and 5 mm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com