Adjustable groove depth measuring device and measuring method

A groove depth, measuring device technology, applied in the field of parts processing and measuring, can solve the problems of increasing the measurement work cost, disadvantageous measurement efficiency, measurement error, etc., and achieve the effects of convenient adjustment and locking, improved measurement efficiency, and convenient and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

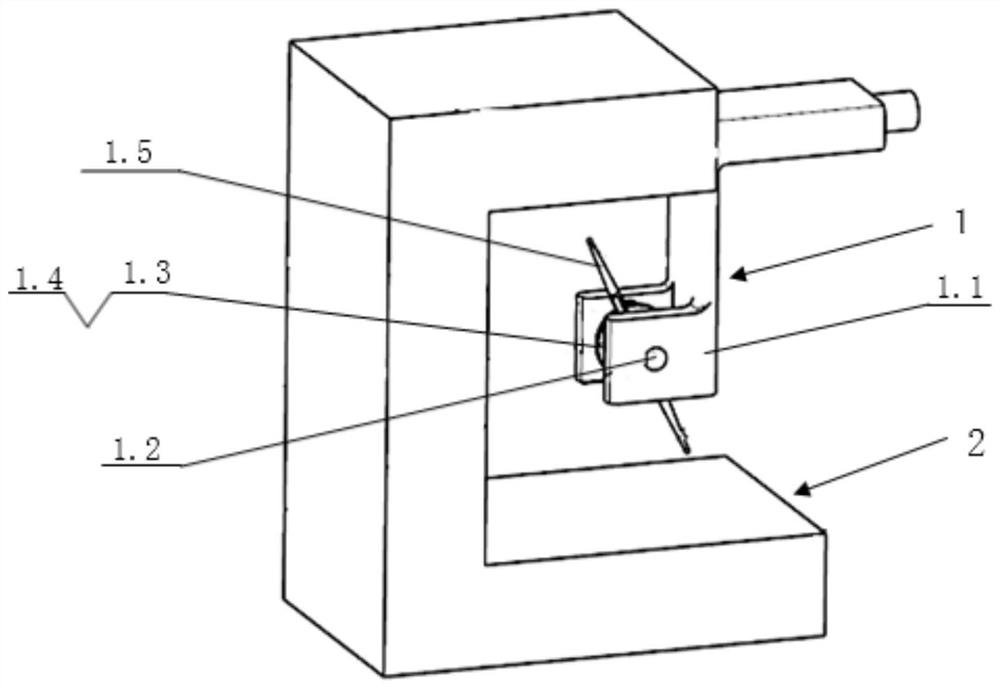

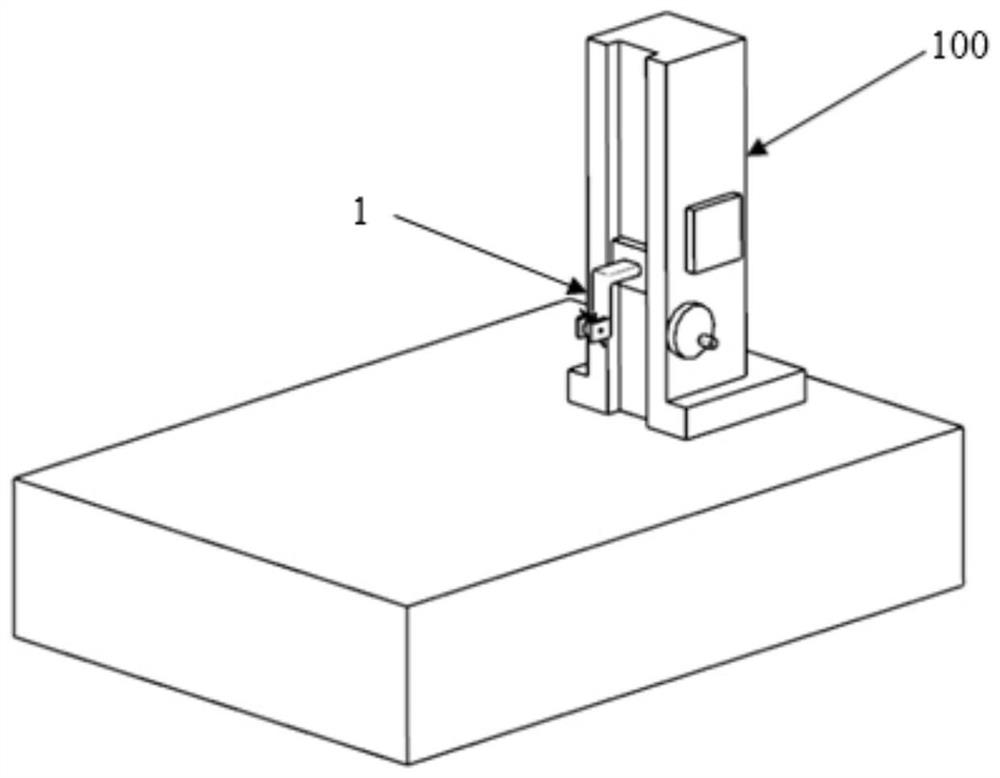

[0037] An adjustable groove depth measuring device, see Figure 1-6 , the invention point is: including a measuring head assembly 1 and a calibration gauge block 2 .

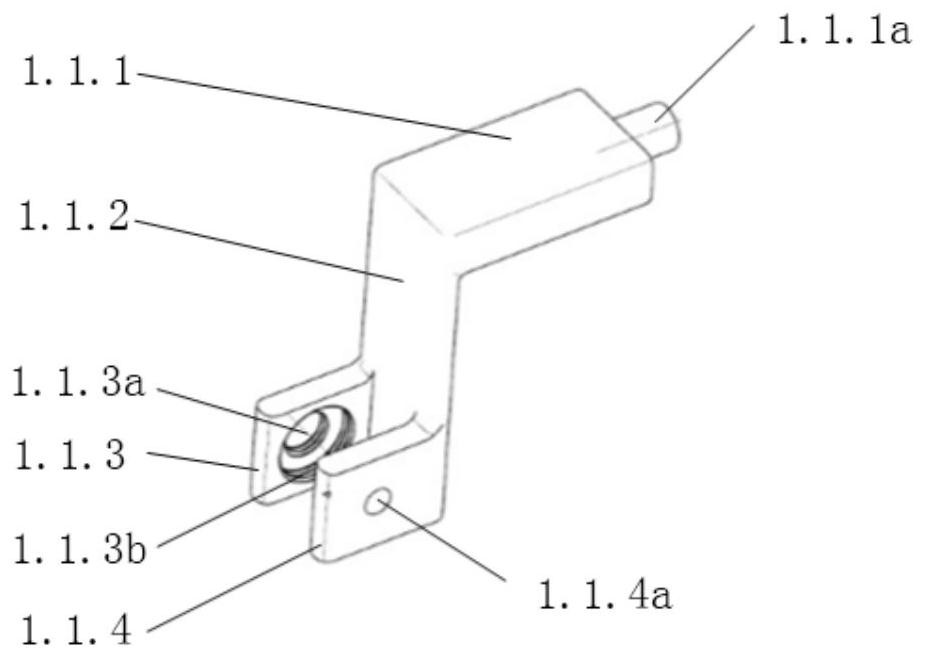

[0038] The measuring head assembly includes a frame 1.1, an insert 1.3, an adjustment block 1.4, a compression screw 1.2 and two measuring pins 1.5. The frame is composed of a tail end 1.1.1, a measuring end and a connecting arm 1.1.2 between them, the tail end is provided with a pin shaft 1.1.1a cooperating with the measuring instrument 100, and the measuring end is composed of two parallel The left and right sides of the support plate are formed, and the accommodation groove is formed between the two sides of the support plate, and the threaded hole 1.1.3a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com