Injection molding machine

An injection molding machine and plastic technology, applied in the field of injection molding machines, can solve the problems of increasing the difficulty of the work of the staff, low injection molding effect, and difficulty in moving the injection molding machine, so as to improve the efficiency of injection molding, improve the effect of injection molding, and facilitate movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

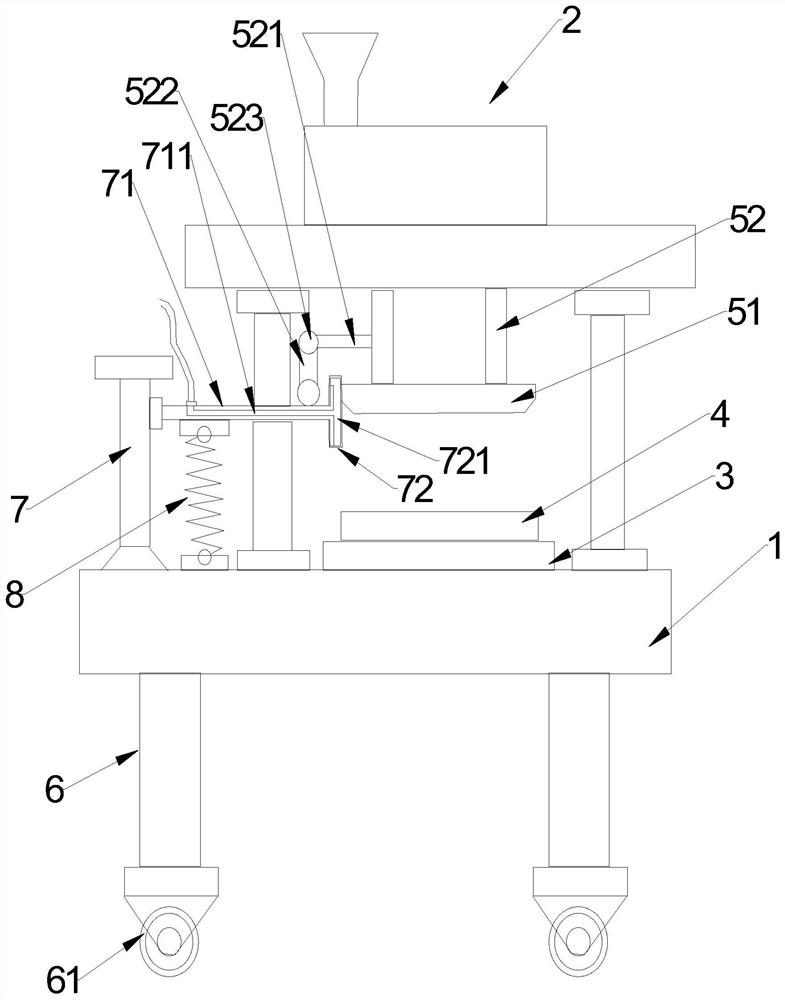

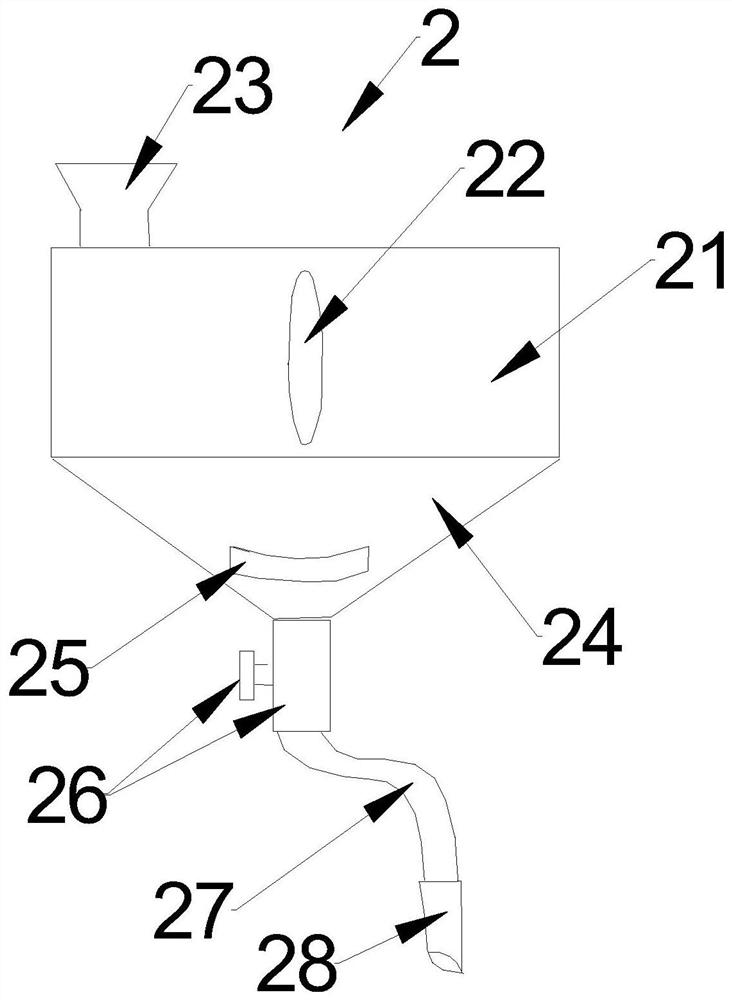

[0014] Such as figure 1 and 2 As shown, a kind of injection molding machine comprises workbench 1, and described workbench 1 is provided with useful injection mechanism 2, injection mold, clamping mechanism 3 and driving mechanism. Said injection mold comprises movable mold assembly and fixed mold assembly 4. The movable mold assembly includes a movable mold 51 and a support rod 52 connected with the movable mold 51, and the injection mechanism 2 includes a plastic storage box 21, an observation window 22, a hopper 23, a funnel hopper 24, and a fixed card 25 And the material guide pipe 26, the observation window 22 is inlaid in the middle of the front surface of the plastic storage box 21, the hopper 24 is inlaid in the left side of the upper surface of the plastic storage box 21, and the funnel 24 is connected by bolts On the lower surface o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap