Sludge drying device and using method thereof

A sludge drying and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high viscosity, easy to block ventilation holes, high sludge viscosity, etc., and improve the sludge reduction ratio , speed up the drying process, increase the effect of contact frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

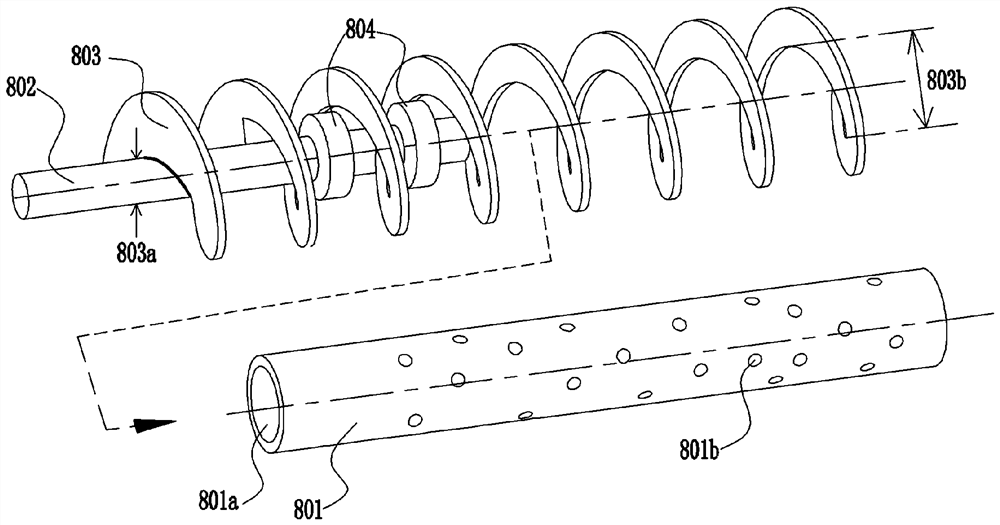

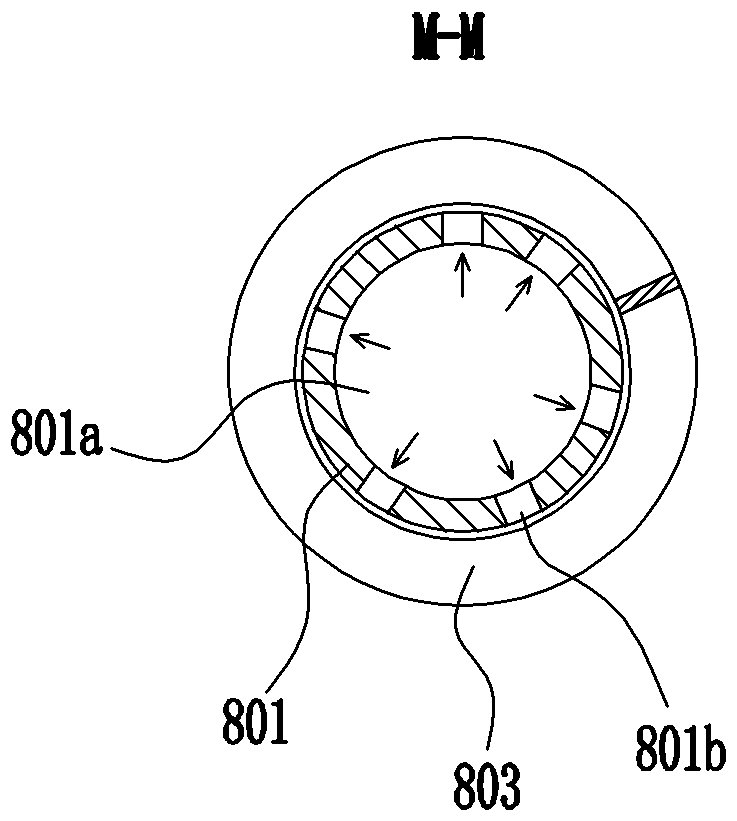

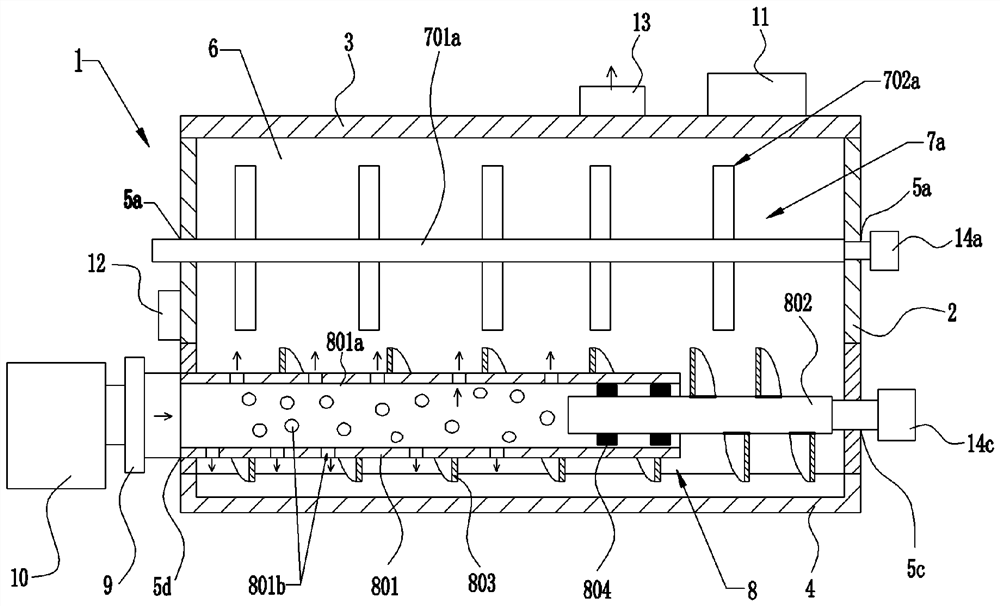

[0042] figure 1 An embodiment of a fluid conveying arrangement according to the application for a sludge treatment plant is shown in a partially cutaway perspective view. figure 2 Shown in cross section figure 1 The structure of the fluid transport assembly at the M-M position, while image 3 Shown in cross section figure 1 The structure of the fluid delivery assembly at the N-N position with the rotation axis. As shown, the fluid delivery assembly S includes a fluid delivery tube or barrel 801 , a rotating shaft 802 and a screw 803 . The screw 803 can also be called a screw or a screw blade, and one end of the screw 803 is fixedly connected to the rotating shaft 802, and the other end is sleeved on the delivery pipe 801, wherein the rotating shaft 802 is connected to the part of the screw 803 Located outside the fluid delivery tube 801, another part of the rotating shaft 802 is rotatably disposed inside the fluid delivery tube 801, so that most of the screw 803 can rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap