Cloth cutting device with cloth cutting length adjusting function

A cutting device, a technology of length and length, applied in the cutting of textile materials, textiles and papermaking, etc., can solve problems such as low efficiency, waste of cloth, and risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

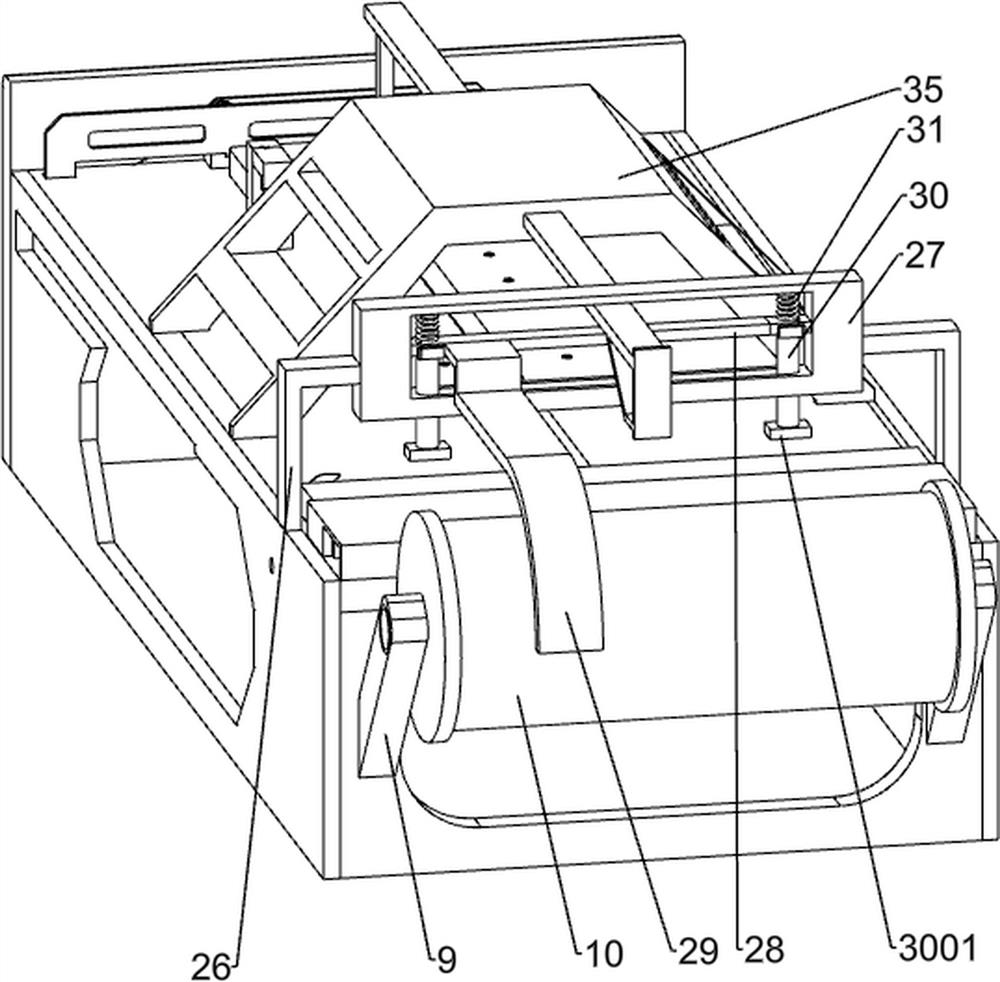

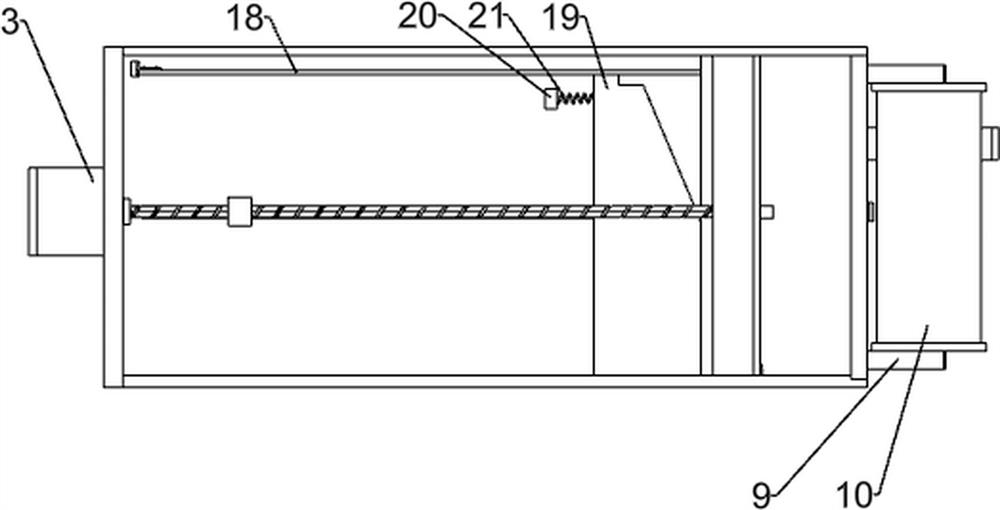

[0029] refer to Figure 1-3 As shown, a cloth cutting device with the function of adjusting the length of the cut cloth includes a mounting table 1, a mounting plate 2, a motor 3, a first connecting plate 4, a mounting block 5, a threaded rod 6, a sliding frame 7, and a sliding pressing rod 701. Pneumatic gripper 8, fixed rod 9, cloth shaft 10, connecting rod 11, second connecting plate 12, adjustment device and cutting device, mounting plate 2 is fixedly installed on the left side of mounting table 1, and a motor is provided on the top of mounting plate 2 3. The output shaft of the motor 3 passes through the left side of the installation platform 1, the output shaft of the motor 3 is connected to the installation platform 1 in rotation, and the middle part of the inner wall on the right side of the installation platform 1 away from the motor 3 is fixedly connected with the first connecting plate 4, the second A mounting block 5 is fixedly installed in the middle of the top of...

Embodiment 2

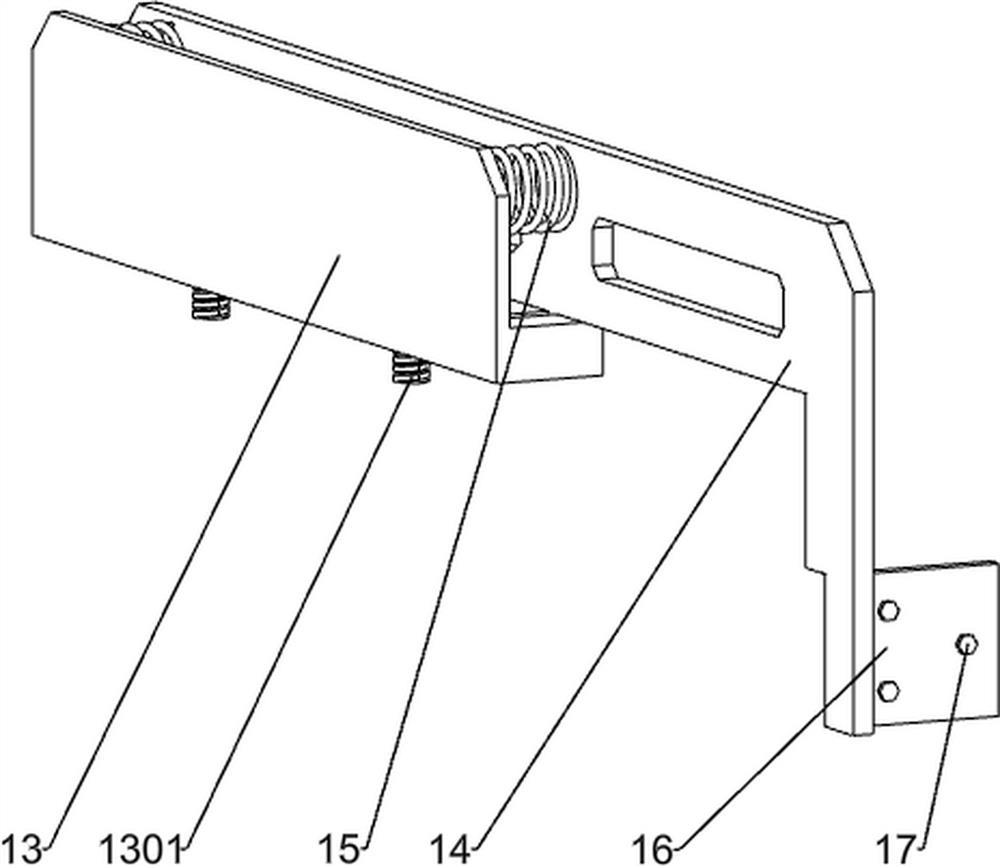

[0032] On the basis of embodiment 1, refer to Figure 4 and Figure 6 As shown, the adjustment device includes an L-shaped connecting frame 13, a first screw 1301, a sliding plate 14, a spring 15, a connecting piece 16, a second screw 17 and a fastening assembly, and multiple pairs are arranged at intervals on both sides of the top opening of the mounting table 1. Threaded hole, the left side of the top of the mounting table 1 is detachably installed with an L-shaped connecting frame 13 through the first screw 1301, the L-shaped connecting frame 13 is slidably connected with a sliding plate 14, and the upper right side of the L-shaped connecting frame 13 is fixedly connected with a spring 15, the right end of the spring 15 is fixedly connected with the upper left side of the sliding plate 14, and the lower part of the right side of the sliding plate 14 is fixedly connected with a connecting piece 16, and the connecting piece 16 is provided with three second screws 17, and the ...

Embodiment 3

[0037] On the basis of embodiment 2, with reference to Figure 5-6 As shown, the cutting device includes a second hook 22, a cutting piece 23, a connecting column 24, a second tension spring 25 and a reset assembly, and the front side of the second connecting plate 12 is slidably connected with the second hook 22, and the second hook 22 is on the top. The cutting piece 23 is fixedly connected, the inner side of the right end of the connecting rod 11 is fixedly connected with the rear end of the connecting column 24, the front end of the connecting column 24 is fixedly connected with the inner wall of the front side of the installation table 1, the second hook 22 is slidingly connected with the connecting column 24, and the connecting rod 11 inner right end is fixedly connected with the rear end of the second extension spring 25, the front end of the second extension spring 25 is fixedly connected with the inner side of the second hook 22, and a reset assembly is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com