Grease injection device and method of ball screw

A ball screw and ball screw technology, which is used in quantitative devices, engine components, engine lubrication, etc., can solve problems such as inability to accurately control the amount of grease added, poor grease uniformity, and inability to effectively ensure grease cleanliness. Achieve the effect of improving quality and efficiency and reducing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

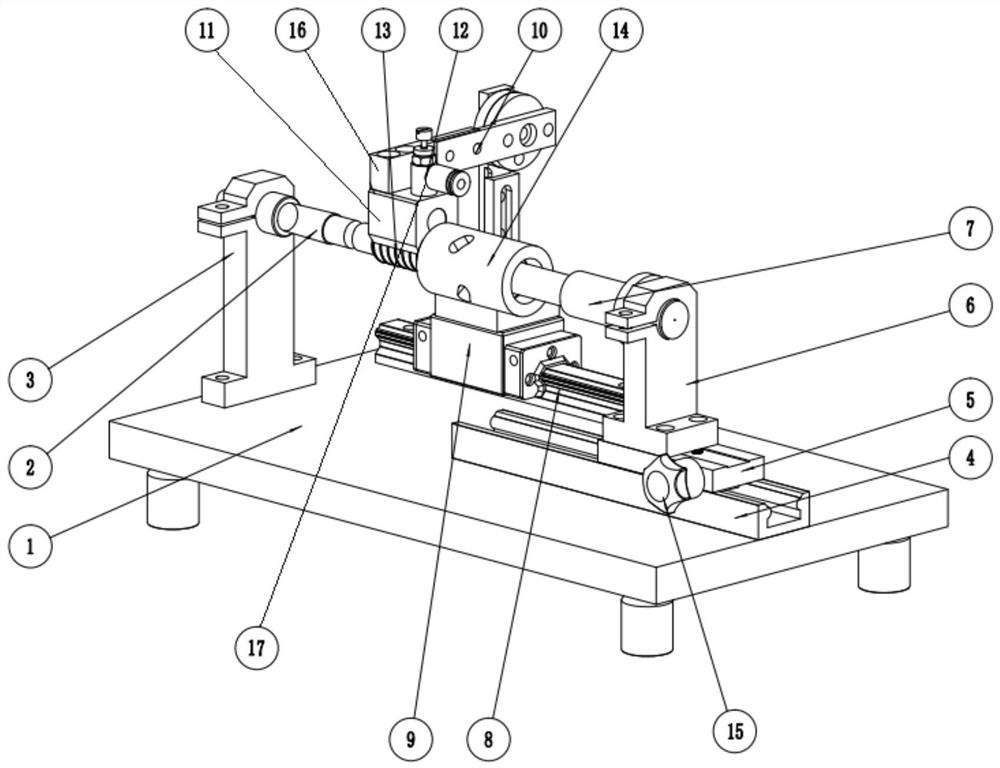

[0027] like figure 1 The shown method of injecting grease into a ball screw includes a base 1 on which first and second positioning brackets 3 and 6 are arranged, and between the first and second positioning brackets 3 and 6 there is a The supporting tip 2 of the ball screw assembly 14 to be lubricated and the base 1 are also equipped with a slider mechanism for sliding the first and second positioning brackets 3 and 6 .

[0028] Specifically, a slider mechanism is provided at the lower end of the second positioning bracket 6 . The slider mechanism includes a slider assembly 5 and a slider slide rail 4 , and a locking screw 15 is arranged on the slider assembly 5 .

[0029] The second positioning bracket 6 slides through the sliding fit of the slider assembly 5 and the slider rail 4 . ; In addition, the second positioning bracket 6 is provided with a positioning replacement rod 7 and a threaded workpiece 13 .

[0030] The grease injection part includes a grease injection par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com