Back-blowing anti-blocking multi-point constant-speed powder sampling device applied to horizontal pipeline

A technology of horizontal pipelines and sampling devices, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of easy wear, heavy workload of sampling personnel, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

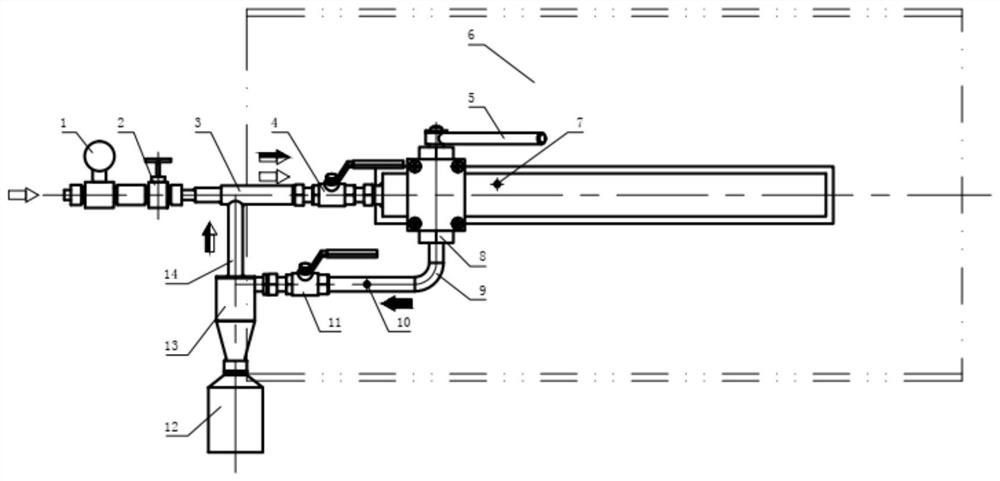

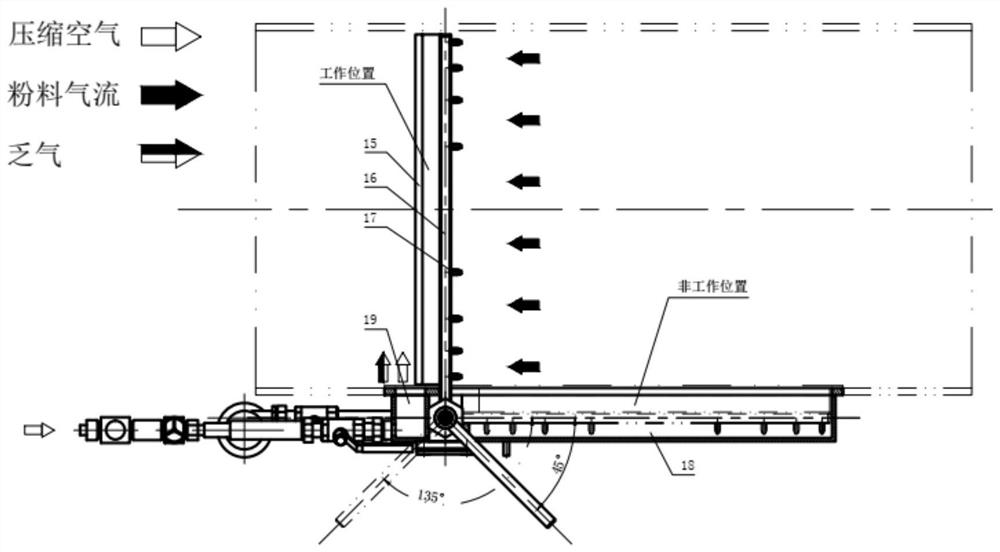

[0021] refer to figure 1 and figure 2 , the anti-blowing and anti-blocking multi-point constant velocity powder sampling device applied to horizontal pipelines according to the present invention includes a sampling pipe 16, a hollow shaft, a sampling connecting pipe 9, a cyclone separator 13, an air extractor 3, and a pressure reducing valve 2 , pressure gauge 1, housing 18 and compressed air source; one end of sampling pipe 16 is closed, and the other end of sampling pipe 16 is docked with the hollow shaft and connected, and several sampling nozzles 17 facing the direction of powder flow are installed on the sampling pipe 16 , one end of the hollow shaft is closed, the other end of the hollow shaft is connected to the inlet of the cyclone separator 13 through the sampling connecting pipe 9, the bottom outlet of the cyclone separator 13 is equipped with a collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com