Steam isokinetic sampling device

A sampling device and constant-velocity sampling technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of increasing the area of steam scouring, reducing welding strength, and affecting welding quality, so as to reduce the cross-sectional area and reduce the Fracture phenomenon, effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

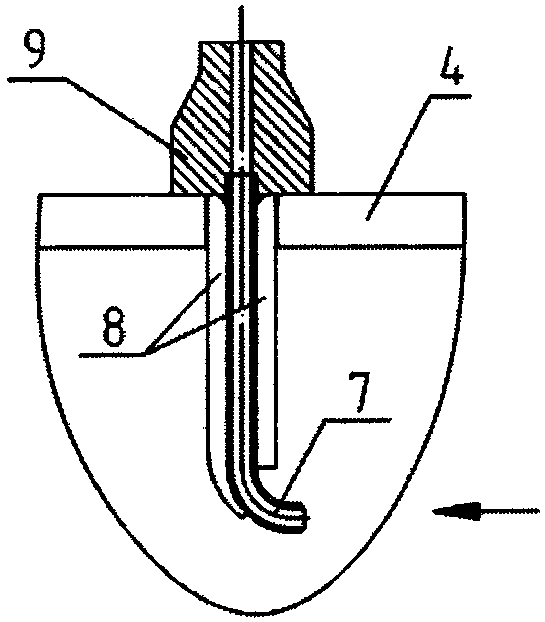

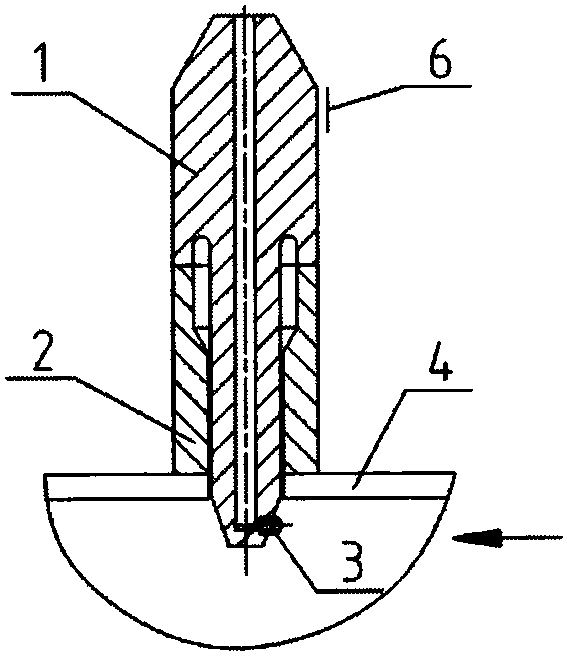

[0027] Such as figure 2 As shown, the steam isokinetic sampling device of the present embodiment comprises a transition socket 2 fixedly connected to the outer wall of the steam pipeline 4, the sampling device 1 is fixedly connected to the transition socket 2, and the lower end of the sampling device 1 extends into the steam pipeline 4, and the sampling device The upper end of the sampling device 1 is provided with an opening, the lower end of the sampling device 1 is closed, and the side wall of the sampling device 1 located in the steam pipeline 4 is provided with a hole facing the flow direction of the working fluid, and the hole and the opening at the upper end of the sampling device 1 are arranged through the device. The pipelines inside the sampling device 1 are connected. The hole facing the flow direction of the working fluid, the opening at the upper end of the sampling device 1 and the axis of the pipeline inside the sampling device 1 form an "L" shape. In the rang...

Embodiment 2

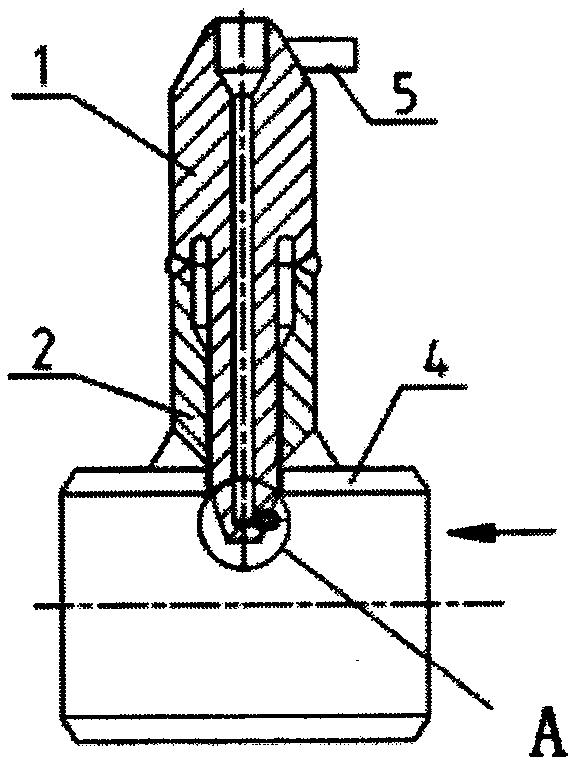

[0035] Such as Figure 5 As shown, the steam isokinetic sampling device of this embodiment is similar to Embodiment 1, the difference is that the lower end of the sampling device 1 is cylindrical, and the hole facing the flow direction of the working fluid is cylindrical, and the sampling probe 3 is not provided therein. , the circumference of the hole facing the flow direction of the working fluid is slightly raised, and the outer edge of the circumference is smoothly transitioned to the side wall of the sampling device 1 .

[0036] When in use, the steam in the steam pipe 4 is sampled through the hole facing the flow direction of the working fluid, and enters the sampling system connected to the upper end of the sampling device 1 after passing through the sampling device 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com