Solid dust sampling probe for use in pipeline

A technology for sampling probes and solids, applied in the direction of sampling devices, etc., can solve problems such as failure to work, errors, and pressure values that are not average values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

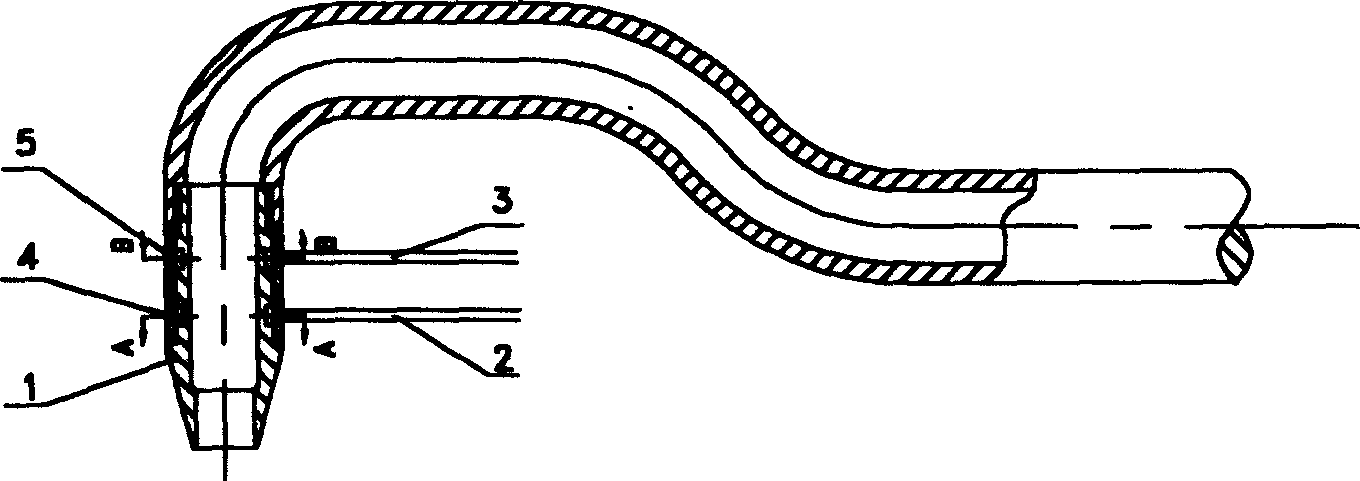

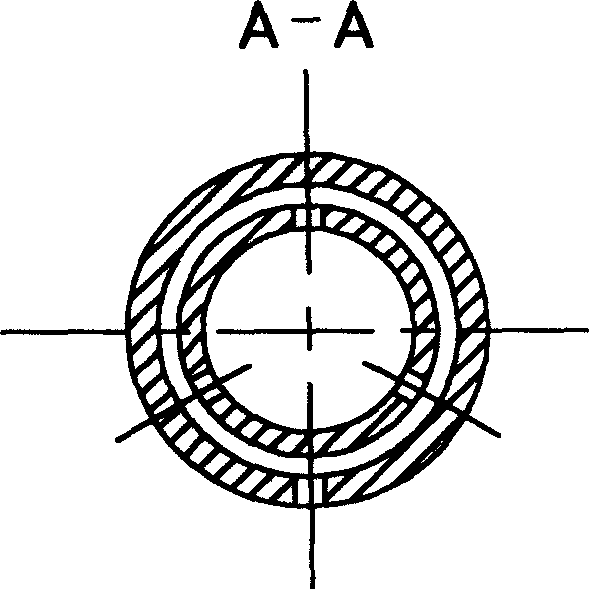

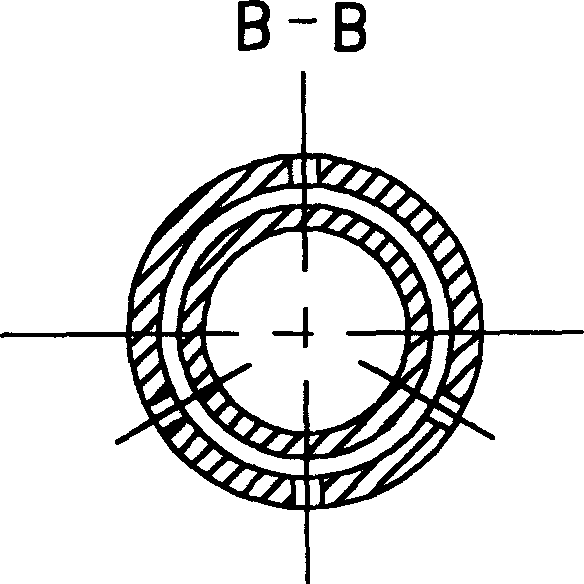

[0007] Embodiment: sampling probe structure such as figure 1 shown. The inner diameter of the sampling probe 1 is 6mm, the inner diameter of the diffuser section is 6.7mm, and the outer diameter is 20mm; the inner and outer pressure ring chambers 4 and 5 are 3mm wide and 2mm high, the inner and outer pressure holes 6 and 8 are 1mm in diameter, and the pressure measuring holes The diameter of 7 and 9 is 2mm, the diameter of pressure pipe 2 and 3 is 8mm, and the wall thickness is 4mm.

[0008] The technical parameters of the sampling device designed in this way are: non-uniform velocity coefficient 3 , The measurement error is less than 5%.

[0009] In the present invention, because the expansion section, the inner and outer pressure ring chambers 4, 5 and the inner and outer pressure taking tubes 2, 3 are added to the sampling inner tube of the sampling probe 1, isokinetic sampling can be realized, and the equipment is very simple. Moreover, the disturbance to the fluid in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com