Industrial tobacco logistics scheduling method based on Lagrange relaxation

A scheduling method and tobacco technology, applied in logistics, commerce, data processing applications, etc., can solve the problems of low order volume, low transportation efficiency, and high transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

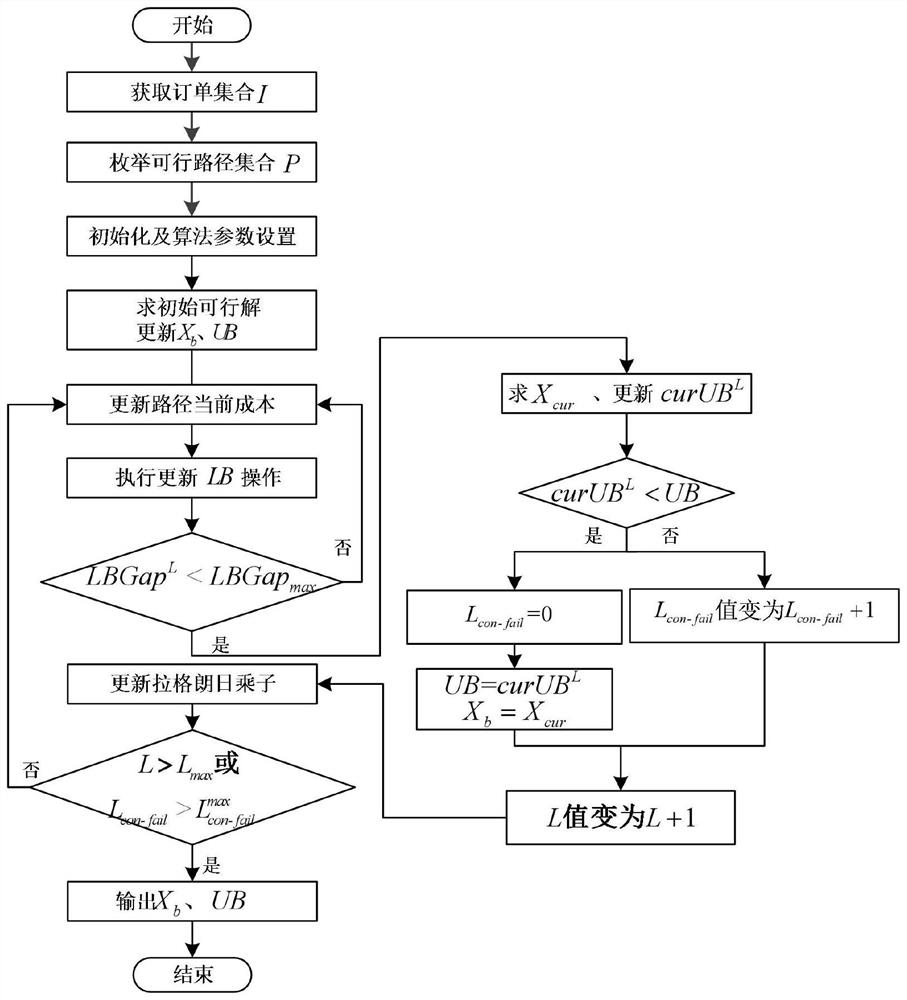

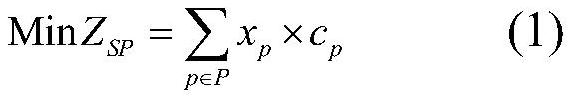

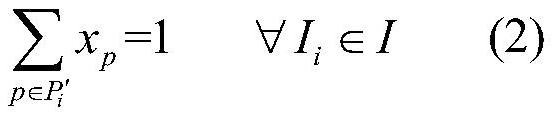

[0100] In this implementation example, an industrial tobacco logistics scheduling method based on Lagrangian relaxation is used to serve the scheduling work of cigarette transportation for industrial tobacco logistics companies. According to the characteristics of industrial tobacco logistics companies and transportation tasks, combined with industrial tobacco logistics companies and The development direction of logistics enterprises takes the important research results of vehicle routing problems as the main means, establishes corresponding mathematical models by analyzing the current situation of industrial tobacco logistics, and designs and formulates a scheduling method suitable for industrial tobacco logistics enterprises with obvious effects. The process is as follows figure 1 As shown, the feasible path set is enumerated according to the characteristics of the industrial tobacco logistics cigarette transportation scheduling problem, based on the set segmentation model mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com