Telescopic pin

A telescopic pin and telescopic technology, applied in the direction of contact parts, etc., can solve the problems that the factory cannot be tinned, the welding column is too short to be soldered, and the scraper cannot be used, so as to improve the tinning rate, improve the connection versatility, and reduce design changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

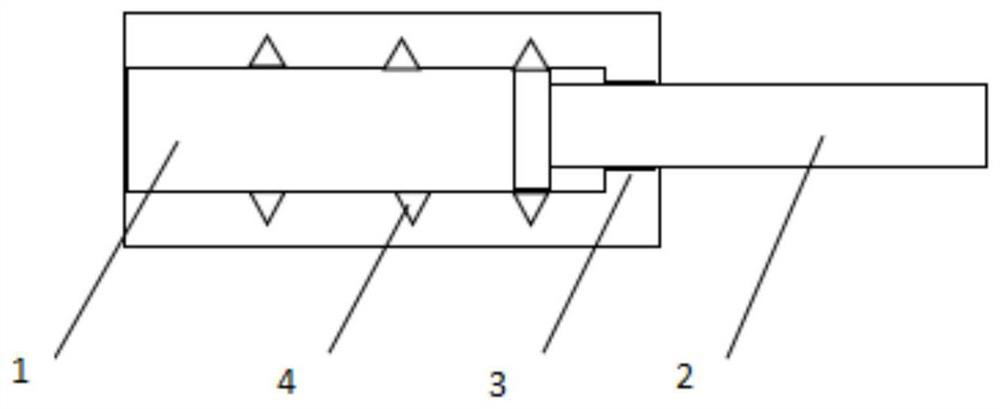

[0018] This embodiment provides a retractable pin, such as figure 1 As shown, it includes: a fixed cylinder 1 and a telescopic pin 2, wherein the telescopic pin 2 is socketed with the fixed cylinder 1, and the fixed cylinder 1 is welded on the board. The contact surface between the fixed cylinder 1 and the telescopic pin 2 is provided with an anti-pull-off buckle 3 to prevent the telescopic pin 2 from being pulled off from the fixed cylinder 1 . The fixed cylinder 1 is provided with a plurality of positioning grooves 4, and the telescopic pins 2 are provided with elastic positioning protrusions matching the positioning grooves 4, so that the length of the telescopic pins can be adjusted, and the length of the telescopic pins is avoided Change by mistake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com