Node Fault Location Method of FBG Sensor Network Based on Twin Node Auxiliary Sensing

A sensor network and fault location technology, applied in biological neural network models, neural learning methods, transmission systems, etc., can solve problems such as waste of sensor resources, increased network complexity, system laying costs, and increased special topology structures, etc., to achieve The effect of improving fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

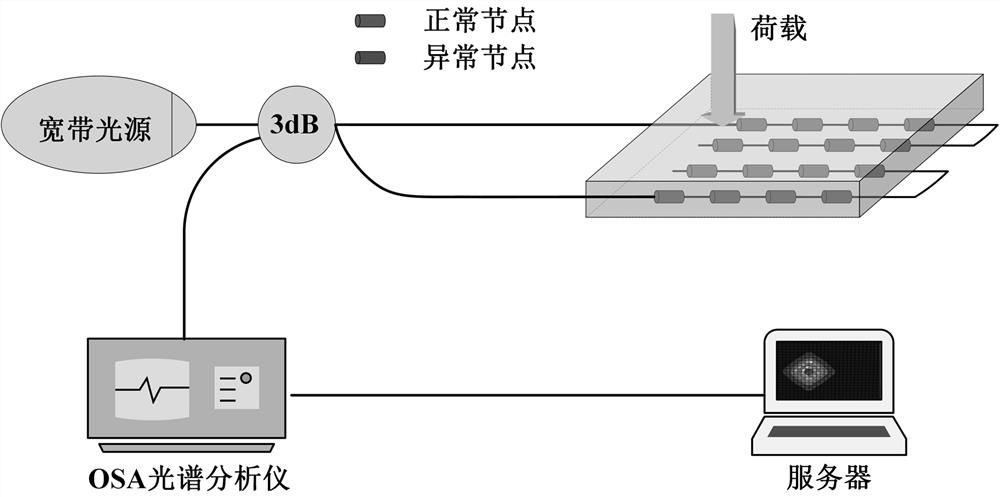

[0031] Please refer to Figure 5 , the present invention introduces twin nodes instead of compensating faulty physical nodes, and then combines the sensing information of twin nodes and normal nodes to jointly predict load point information, and specifically provides a FBG sensor network node fault location method based on twin node auxiliary sensing, Include the following steps:

[0032] Step S1: Obtain the original load data of the monitored structure by laying a preset number of FBG sensors on the monitored structure; Quantity, center wavelength shift of FBG sensors in different positions and other information,

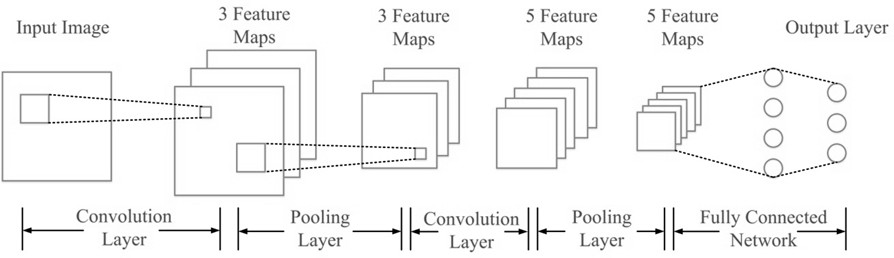

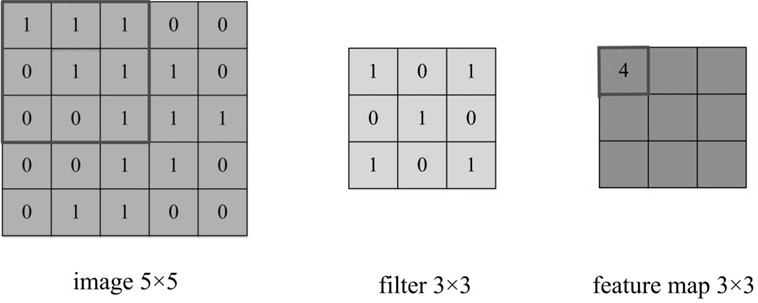

[0033] Step S2: Preprocess the original data of the load. After the original data is acquired, it cannot be directly used for model training, and preliminary processing is required. In order to ensure that the extracted feature quantity ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap